Recycling method of waste masks

A mask and cover body technology, applied in the field of polymer materials, can solve the problems of environmental pollution of discarded masks, achieve the effects of reducing environmental pollution, improving recycling efficiency, and reducing energy consumption and pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

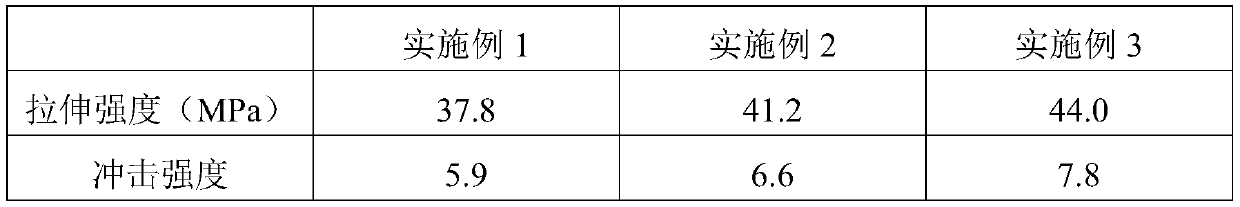

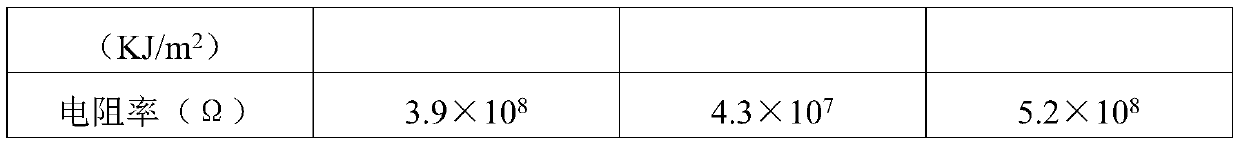

Embodiment 1

[0027] A kind of recycling method of discarded mask, described recycling method comprises the steps:

[0028] (1) The bridge of the nose strip of the discarded mask is removed, the cover body and the lanyard of the discarded mask are made into fragments, and the fragments of the mask are obtained, dried and set aside; the material of the cover body is a non-woven fabric made of polypropylene resin, The melt index of the non-woven fabric is 40g / 10min~3000g / 10min, and the material of the lanyard is polyurethane elastomer;

[0029] (2) The mask fragments after drying and coupling agent, reinforcing agent, antioxidant, pigment, antibacterial agent and antistatic agent are first carried out banburying processing with a banburying extruder, and then extrusion processing, so Described banbury extruder comprises banbury section and extrusion section, and described banbury section is banbury mixer, and described extrusion section is single-screw extruder, and the banbury rotating speed...

Embodiment 2

[0033] A kind of recycling method of discarded mask, described recycling method comprises the steps:

[0034] (1) The bridge of the nose strip of the discarded mask is removed, the cover body and the lanyard of the discarded mask are made into fragments, and the fragments of the mask are obtained, dried and set aside; the material of the cover body is a non-woven fabric made of polypropylene resin, The melt index of the non-woven fabric is 40g / 10min~3000g / 10min, and the material of the lanyard is polyurethane elastomer;

[0035] (2) The mask fragments after drying and coupling agent, reinforcing agent, antioxidant, pigment, antibacterial agent and antistatic agent are first carried out banburying processing with a banburying extruder, and then extrusion processing, so Described banburying extruder comprises banburying part and extruding part, and described banburying part is banbury mixer, and described extruding part is single-screw extruder, and the banburying rotating speed...

Embodiment 3

[0039] A kind of recycling method of discarded mask, described recycling method comprises the steps:

[0040] (1) The bridge of the nose strip of the discarded mask is removed, the cover body and the lanyard of the discarded mask are made into fragments, and the fragments of the mask are obtained, dried and set aside; the material of the cover body is a non-woven fabric made of polypropylene resin, The melt index of the non-woven fabric is 40g / 10min~3000g / 10min, and the material of the lanyard is polyurethane elastomer;

[0041] (2) The mask fragments after drying and coupling agent, reinforcing agent, antioxidant, pigment, antibacterial agent and antistatic agent are first carried out banburying processing with a banburying extruder, and then extrusion processing, so Described banbury extruder comprises banbury section and extrusion section, and described banbury section is banbury mixer, and described extrusion section is single-screw extruder, and the banbury rotating speed o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com