Air particle dust pumping and discharging device and method of polishing equipment

An air particle and equipment technology, applied in the field of polishing equipment air particle dust extraction, polishing equipment air particle dust extraction device field, can solve the problem of ineffective removal of particles, scratches, affecting the substrate wafer polishing yield, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

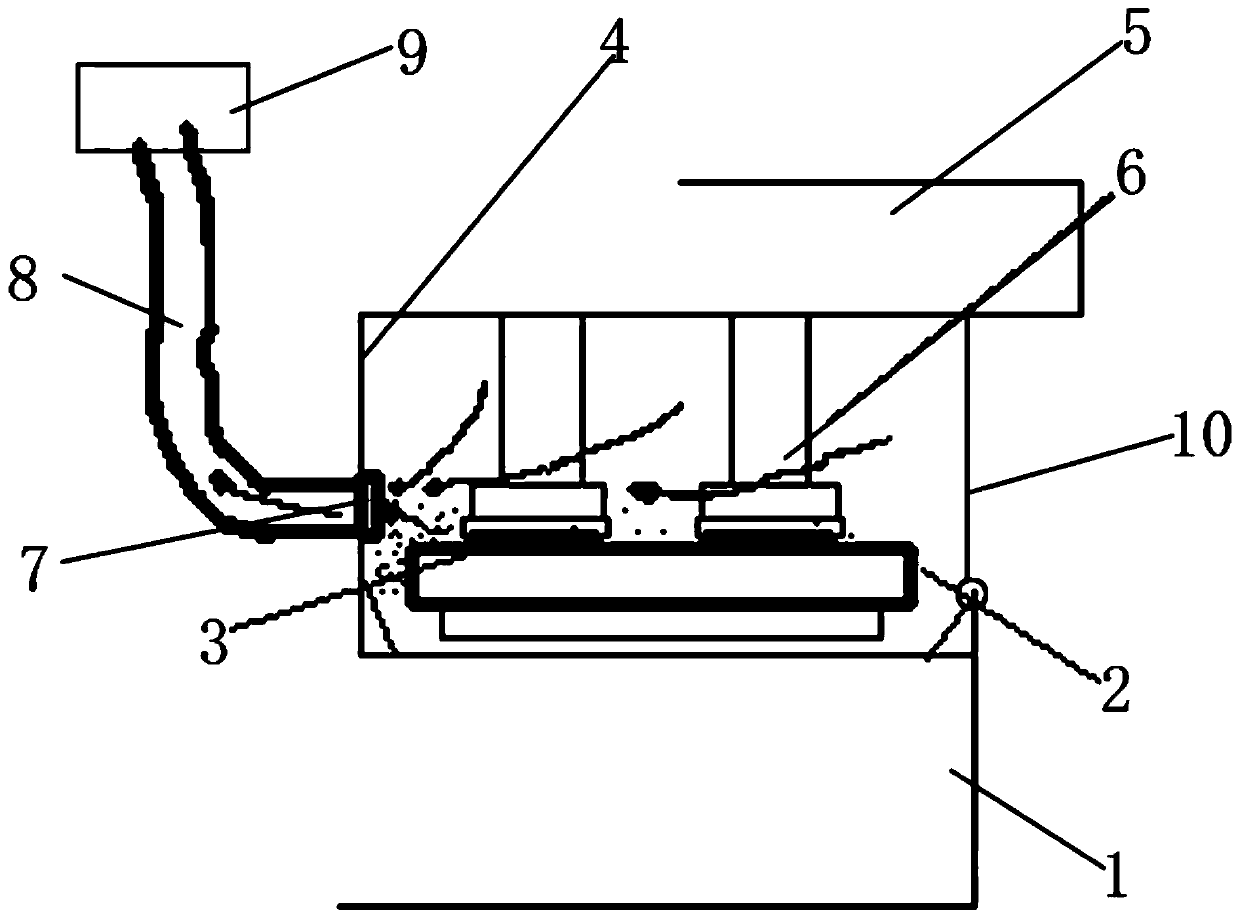

[0019] A polishing equipment air particle dust extraction device, see figure 1 , figure 2 : It includes a polishing equipment base 1, a fixed plate turntable 2 is arranged on the polishing equipment base 1, a ceramic disk wafer carrier 3 is placed on the fixed plate turntable 2, the polishing equipment base 1 is connected to an upper mounting frame 5 through an upwardly convex arc plate 4, The upper mounting frame 5 is provided with several exposed polishing turntables 6, the polishing turntable 6 is used for the polishing of the wafer on the ceramic disk wafer carrier 3, and the arc plate 4 is provided with at least one exhaust air outlet 7, each exhaust The tuyere 7 is externally connected to the exhaust power device 9 through the exhaust pipe 8, and closes the original vertical exhaust outlet.

[0020] In a specific embodiment, two suction and exhaust outlets 7 are symmetrically arranged on the arc plate 4 with respect to the vertical plane of the arc plate 4;

[0021] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com