Rotating blade capable of improving stirring efficiency

A technology of rotating blades and blades, which is applied to mixers, dissolvers, mixers and other directions with rotating stirring devices to achieve the effects of stable chemical and physical properties, simple loading and unloading process, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

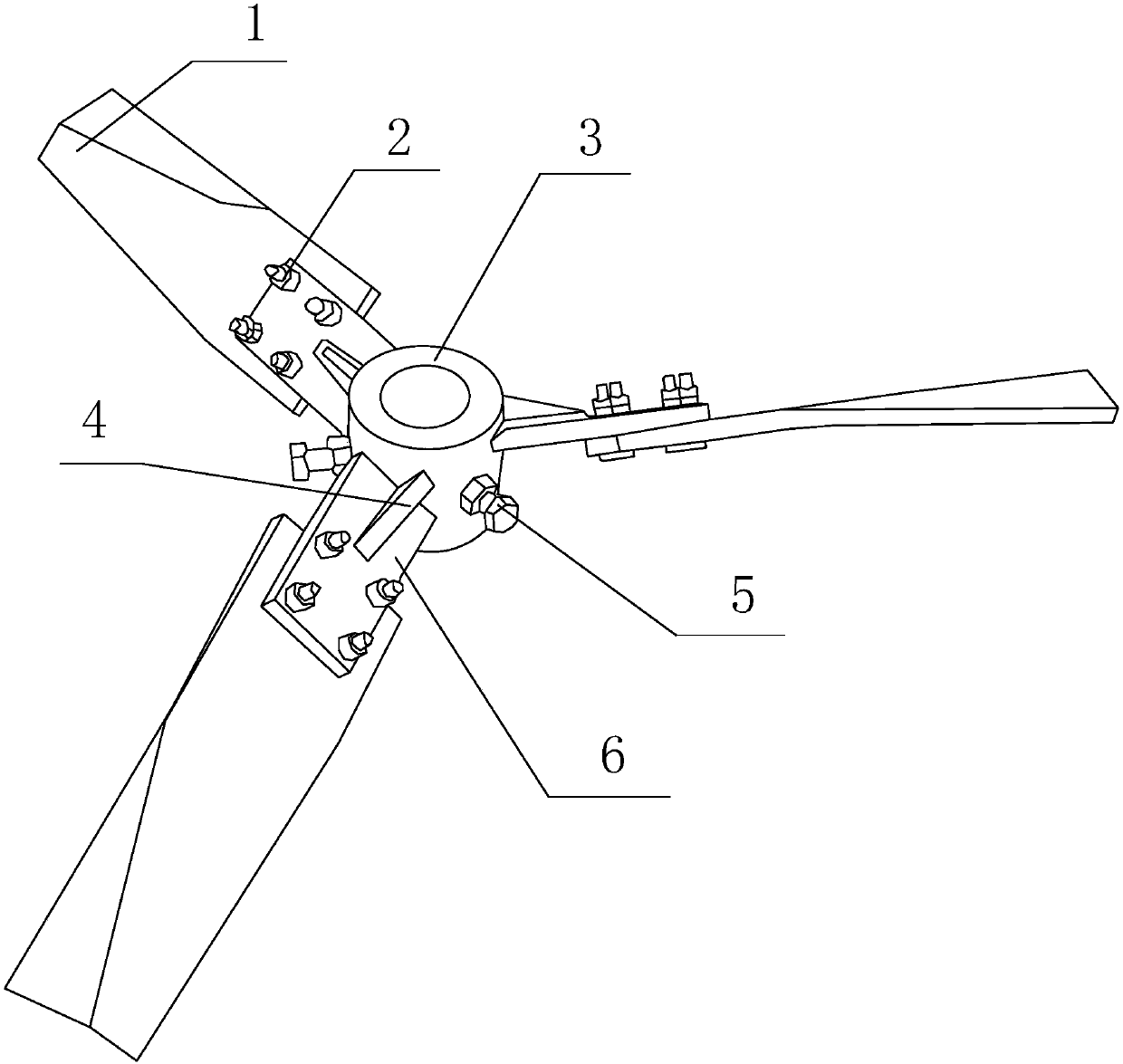

[0016] Such as figure 1 As shown, the rotating blade that can improve the stirring efficiency includes a mounting ring 3 with several threaded holes on the outer wall, and several blades 1 are provided on the side wall of the mounting ring 3 . During use, the mounting ring 3 drives the rotation of the blade 1 along with the rotation of the rotating shaft.

[0017] Several mounting plates 6 are arranged on the side wall of the mounting ring 3 , one end of the mounting plate 6 is connected to the side wall of the mounting ring 3 , and the other end is connected to the blade 1 .

[0018] A rib 4 is arranged between the installation plate 6 and the installation ring 3 , one side of the rib 4 is in contact with the outer wall of the installation ring 3 , and the other side is in contact with the installation plate 6 . By setting the rib plate 4, the firmness between the mounting plate 6 and the mounting ring 3 is increased, making it more stable during the working process.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com