Disassembling and assembling robot for high-temperature connecting pipe

A technology for connecting pipes and robots, which is applied in the direction of manipulators, chemical instruments and methods, and cleaning hollow objects, etc. It can solve problems such as high temperature of argon gas pipelines, obstruction of joint insertion and removal, and dangerous operation, so as to improve operating efficiency and integration. High, the effect of eliminating hidden dangers in the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings. The embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

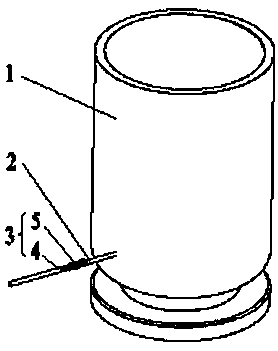

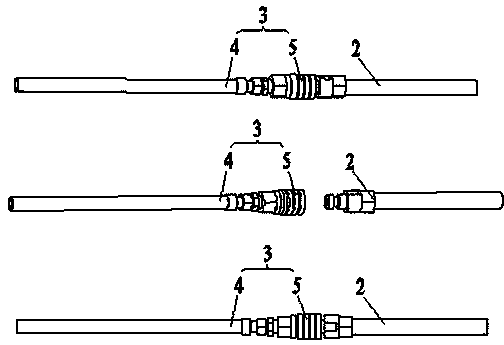

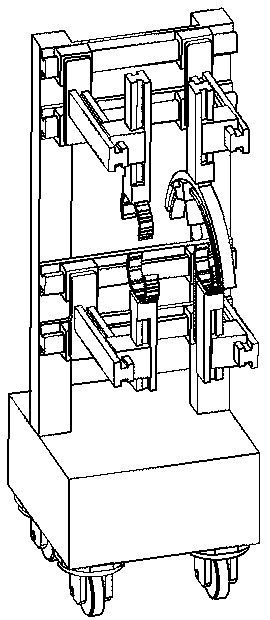

[0044] The function of the robot in this application includes the knocking of condensed steel slag at the pipeline joints and the disassembly and assembly of high-temperature pipeline quick connectors. The structure includes a base mechanism 13, a support mechanism 12, four stations ABCD and an actuator. Wherein the base mechanism 13 comprises a counterweight base plate 8 and a universal power wheel 9 ( Figure 5 ). Support mechanism 12 comprises vertical support 7, upper one-level slide rail 10 and lower one-level slide rail 11 ( Figure 5 ). The four stations of ABCD are set in the counterclockwise direction, the slide rails and sliding sleeves of the four stations of ABCD ( Image 6 , Figure 7 ),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com