A fully automatic dispensing machine

A glue dispenser, fully automatic technology, applied to the device and coating of the surface coating liquid, can solve the problem of consuming a lot of human resources, reducing the working efficiency of the glue dispenser, etc., to reduce the consumption of human resources, improve Contact fixing effect, effect of improving clamping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

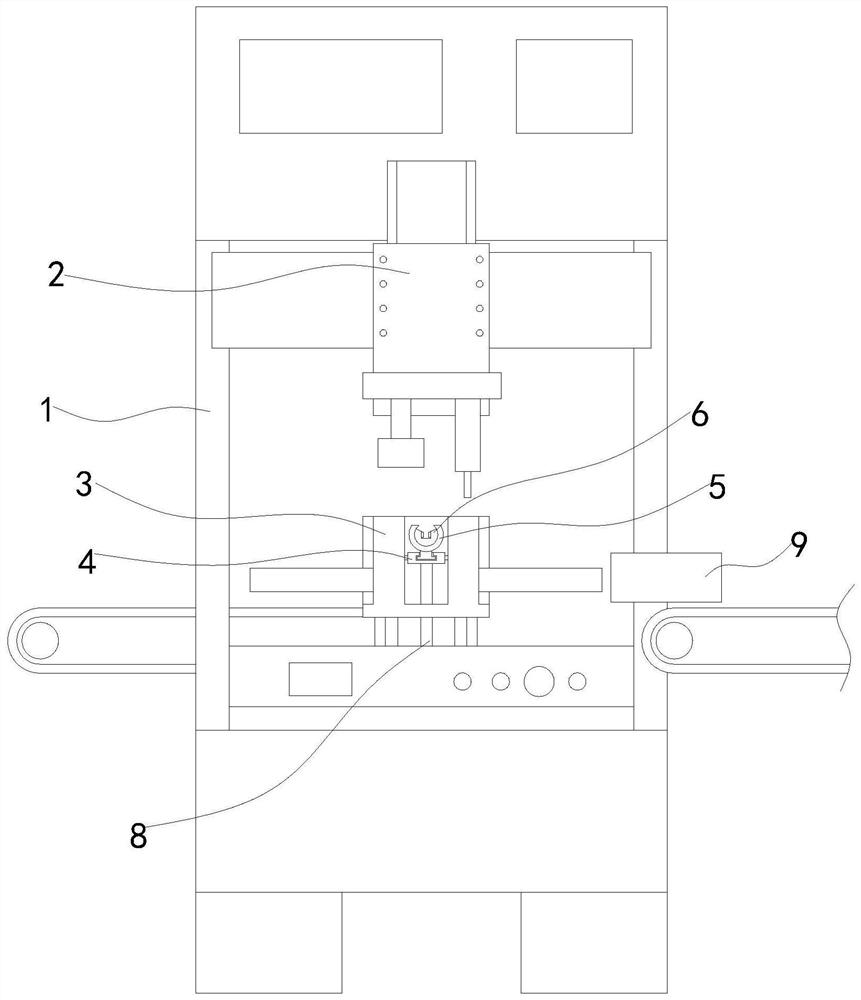

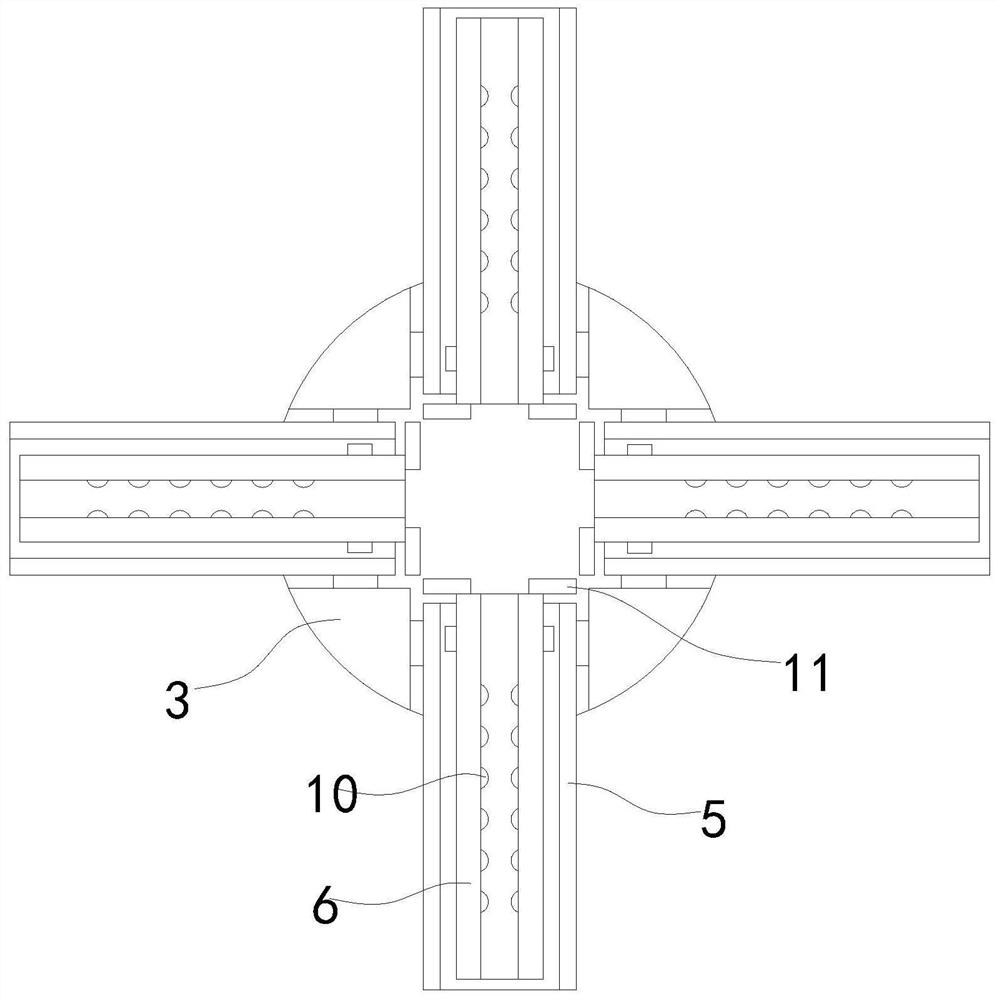

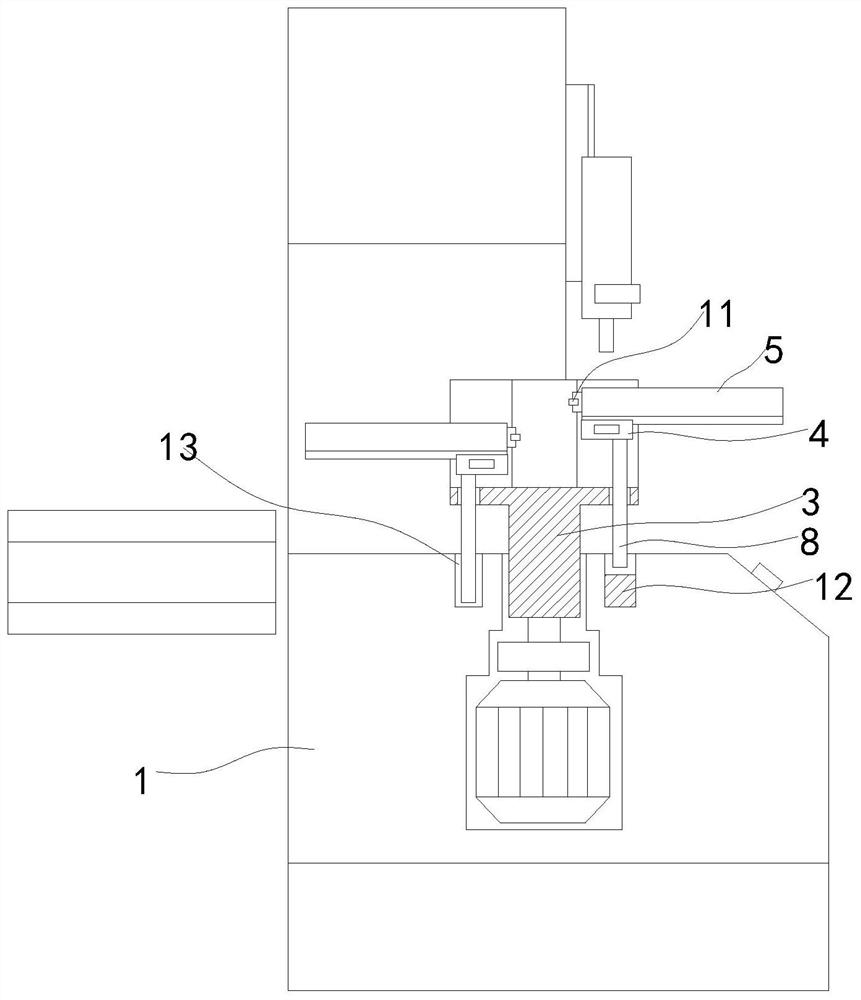

[0026] see Figures 1 to 8 , a schematic diagram of the planar structure and a schematic diagram of the three-dimensional structure of a fully automatic dispensing machine.

[0027] A fully automatic dispensing machine, comprising a device main body 1, a workpiece rotating table 3 is movably installed at the lower end of the device main body 1, an inner moving rod 5 is movably installed inside the workpiece rotating table 3, and a baffle plate 9 is fixedly installed on the right side of the device main body 1 , The workpiece guide plate 7 is fixedly installed at the rear end of the baffle plate 9 .

[0028] In the specific implementation, the workpiece holder 6 is movably installed inside the moving rod 5, the clamping block 10 is movably installed inside the workpiece holder 6, and the dispensing device 2 is movably installed on the upper end of the device main body 1, so that the required While the workpiece being processed is put into the workpiece holder 6 and fixed, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com