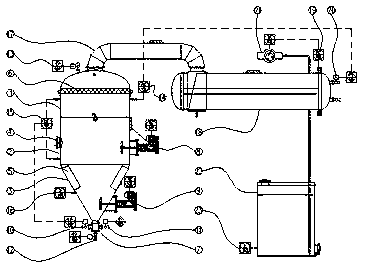

Indirect condensation and vacuum freezing crystallizer

A technology of vacuum freezing and crystallizer, which is applied in the directions of heat exchange cooling crystallization, solution crystallization, evaporation separation crystallization, etc., which can solve the problems of low energy efficiency, high cost, and large amount of steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: feed material liquid comprises following raw material by weight: LiOH 4.0%, NaOH 1.0%, NaOH 2 SO 4 30.0%, the temperature rise of the boiling point is about 10°C, and the feed temperature is 30°C;

[0044] When P1=2300Pa(A), the gas-liquid reaches equilibrium and starts to boil;

[0045] When P2=1700Pa(A), T2=25℃, Na starts to precipitate 2 SO 4 ﹒ 10H 2 O;

[0046] When P3=610(A), T3=10℃, reaching the crystallization end point;

[0047] At this time, the feed liquid contained the following raw materials in parts by weight: LiOH 11.7%, NaOH 2.9%, NaOH 2 SO 4 7.1%. Na 2 SO 4 ﹒ 10H 2 The O crystallization rate is 91.9%, the evaporation rate is 3.4%, and the LiOH concentration ratio is 2.9 times.

Embodiment 2

[0048] Embodiment 2: feed material liquid comprises following raw materials in parts by weight: LiOH 3.0%, NaOH 0.6%, NaOH 2 SO 4 30.0%, the temperature rise of the boiling point is about 5°C, and the feed temperature is 28°C;

[0049] When P1=2800Pa(A), the gas-liquid reaches equilibrium and starts to boil;

[0050] When P2=1800Pa(A), T2=21℃, Na starts to precipitate 2 SO 4 ﹒ 10H 2 O;

[0051] When P3=610(A), T3=5℃, reaching the end point of crystallization;

[0052] At this time, the feed liquid contained the following raw materials in parts by weight: LiOH 9.2%, NaOH 1.8%, NaOH 2 SO 4 4.2%. Na 2 SO 4 ﹒ 10H 2 The O crystallization rate is 95.6%, the evaporation rate is 3.9%, and the LiOH concentration ratio is 3.1 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Evaporation rate | aaaaa | aaaaa |

| Evaporation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com