Coaxial opposite rotor differential motor and new energy automobile

A coaxial pair and differential motor technology, applied in electric vehicles, motors, motor vehicles, etc., can solve the complex structure of the hub motor and its control system, the limitation of the driving mode of the hub motor wheel side motor, the increase of vehicle structure cost and Operating costs and other issues, to achieve cost savings and process difficulty, is conducive to lightweight, save the effect of mechanical differential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

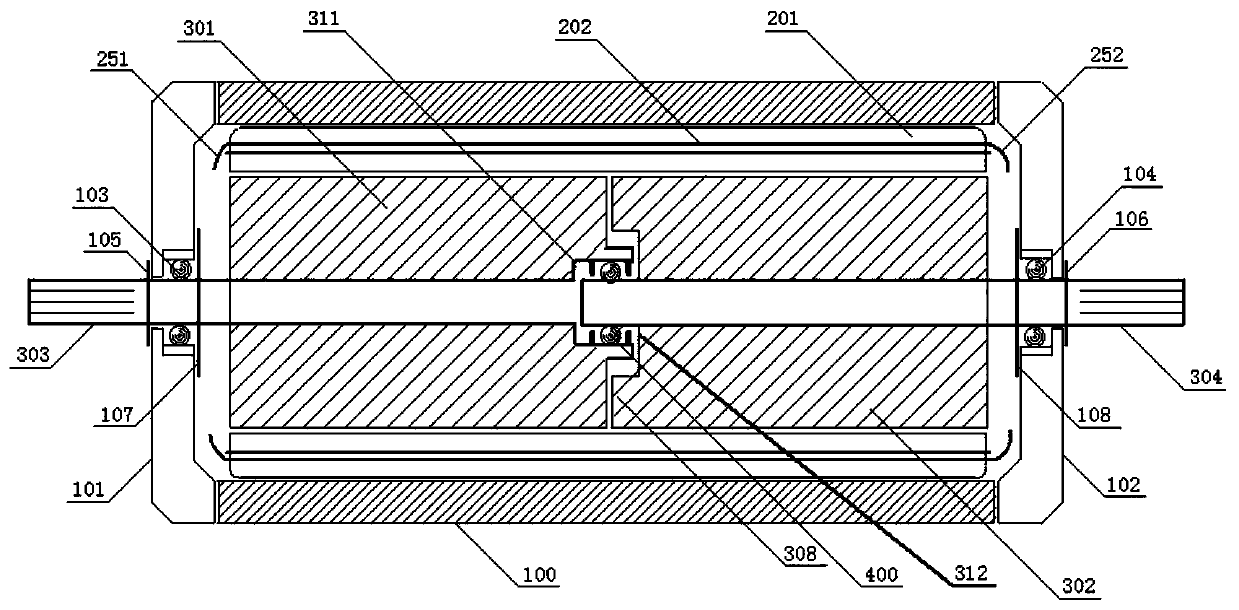

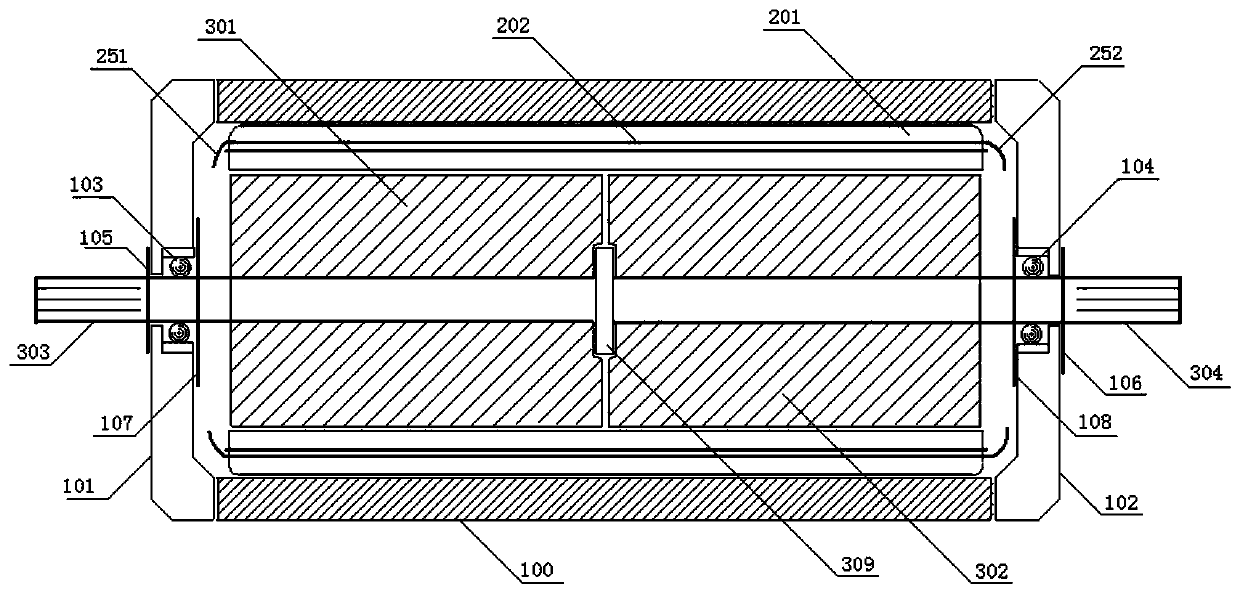

[0040] Such as figure 1 As shown, a coaxial opposed rotor differential motor includes a motor casing 100, a stator 201, a first rotor 301 and a second rotor 302 in the form of a coaxial assembly, wherein the casing part includes a left end cover 101 and right end cap 102.

[0041] The stator 201 is the stator of an asynchronous motor, including a stator core and a stator winding 202 (a part of the winding end is also shown in the figure, such as 251 and 252), the stator is assembled in the motor casing, and the stator winding is assembled on the stator core. In the slot circuit, the length of the straight conductor part of the stator winding is equal to the sum of the axial length of the effective magnetic core of the first rotor and the axial length of the effective magnetic core of the second rotor, and the magnetic field generated by the stator winding is generated by the first winding and the second winding Shared, both the first rotor and the second rotor are the rotor s...

Embodiment 2

[0049] A coaxial opposed rotor differential motor, comprising the aforementioned coaxial opposed rotor differential motor, the first output shaft of the differential motor outputs power through a speed reducer, and the second output shaft passes through another speed reducer External output power, such as Figure 8 As shown,.

[0050] It is easy to understand that the present invention also provides a coaxial opposed rotor differential motor, and an electronic control module is installed in the motor casing, which is beneficial to detect and control the current of the stator winding, realize a compact integrated design, reduce the Small electromagnetic pollution and signal and energy transmission loss.

[0051] In a second aspect, a voltage control method for a coaxial opposed-rotor differential motor is provided.

Embodiment 3

[0053] The voltage control method includes the following steps, such as Figure 9 Shown:

[0054] ① Obtain the first output shaft speed signal SP1 and the second output shaft speed signal SP2 by detecting the speed of the first output shaft and the second output shaft of the coaxial opposite rotor differential motor, and transmit the signals SP1 and SP2 to a Electronic Control Unit ECU,

[0055] ②The electronic control unit ECU compares the signals SP1 and SP2, and judges whether the speed difference reflected by the two signals exceeds the preset set value,

[0056] ③ When the speed difference reflected by the two signals does not exceed the preset set value, the electronic control unit ECU defaults to the speed difference, continues to monitor the two speed signals SP1 and SP2, and does not regulate the power supply voltage; when the speed reflected by the two signals When the difference exceeds the preset set value, the electronic control unit ECU regulates the power supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com