Lubrication structure for rotating machinery

A technology of rotating machinery and structure, applied in the field of lubricating structure of rotating machinery, can solve problems such as the limitation of the amount of lubricating oil, the scattering of lubricating oil, and achieve the effect of efficient lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

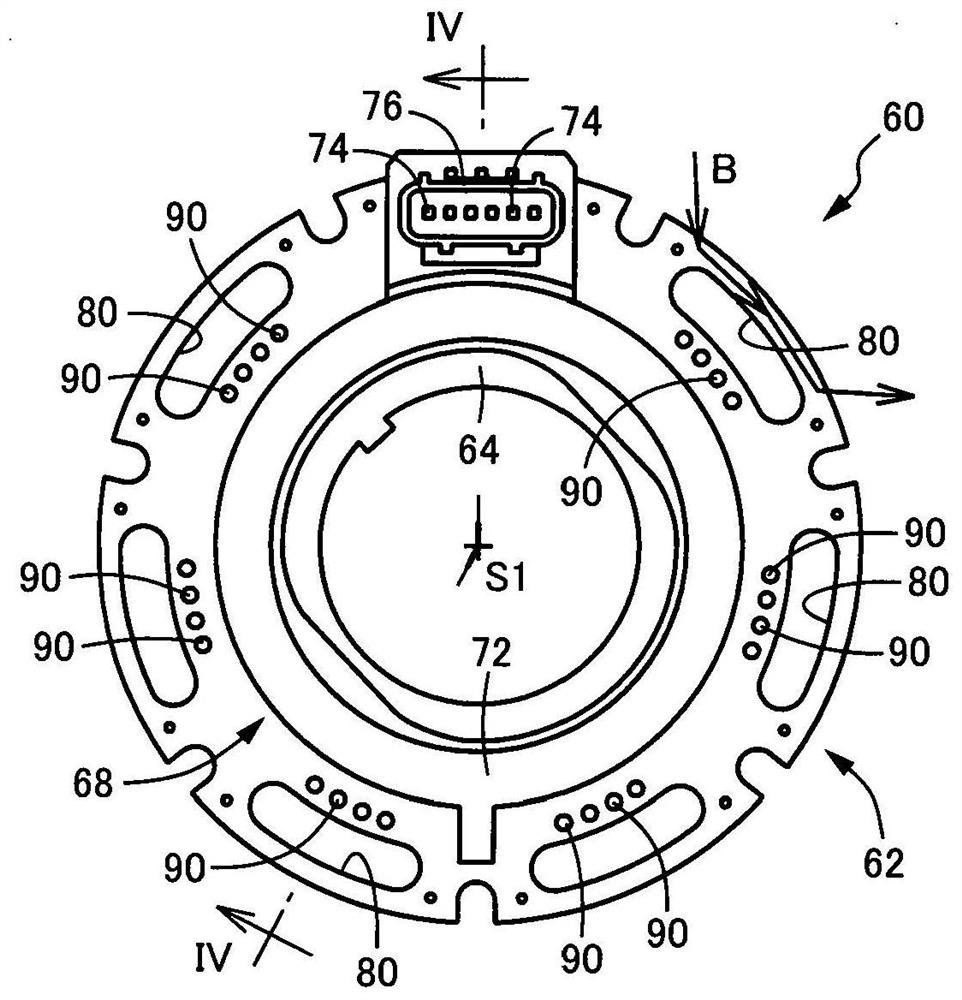

Image

Examples

Embodiment Construction

[0031] The present invention is suitably applied to, for example, a lubricating structure of a rotating machine (a motor or a motor generator) used as a driving force source of a vehicle, but can also be applied to a rotating machine other than a vehicle. It can also be applied to a rotating machine exclusively used as a generator. The lubricating oil passage may be constituted by, for example, only the fluid passage provided on the wall of the casing, but a pipe separate from the casing may be attached to the inside of the casing, and the pipe may be used as the lubricating oil passage. To this lubricating oil passage, for example, the lubricating oil cooled by the oil cooler may be supplied, but the lubricating oil may be supplied without passing through the oil cooler.

[0032] At least a part of the opening on the bearing side of the through-oil hole provided in the resolver stator may be exposed on the inner peripheral side of the fixing part to the casing, and the lubric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com