Method for cutting glass

A glass and glass cutting technology, which is applied in the direction of glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., can solve the problems of affecting operators and splashing of glass slag, and achieve the effects of avoiding splashing, high degree of automation, and easy adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

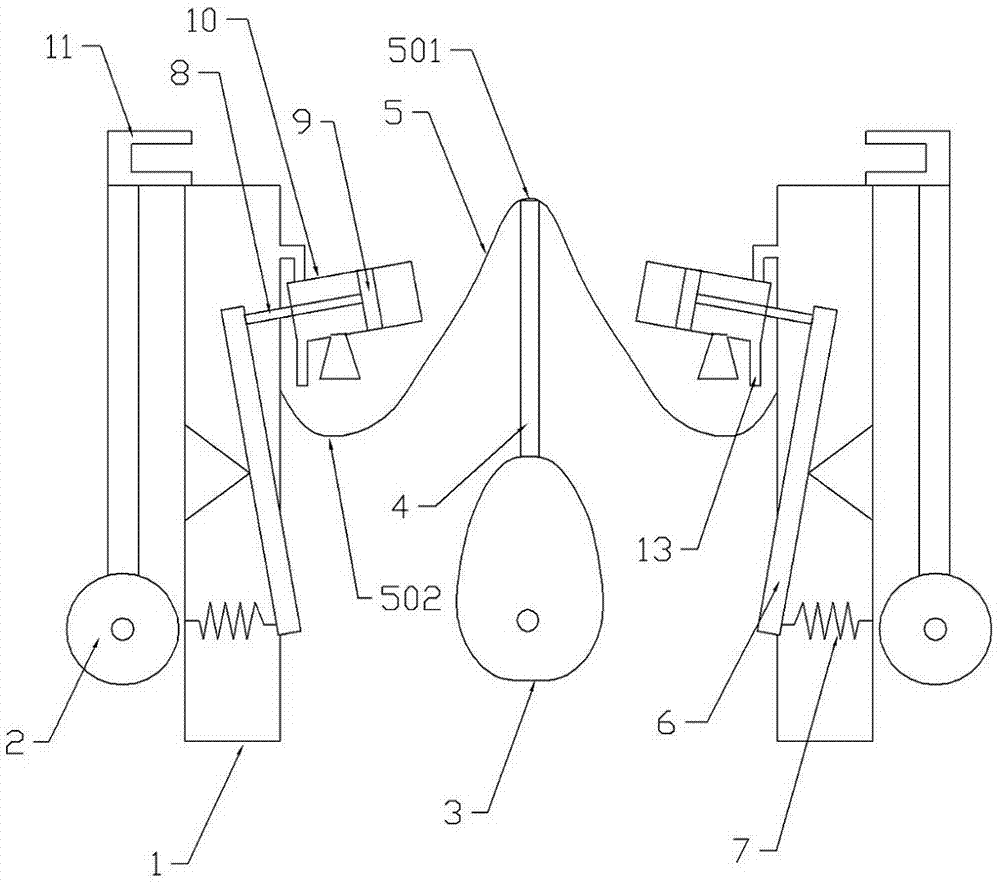

[0021] The reference signs in the drawings of the description include: support frame 1, rotary cylinder 2, cam 3, ejector rod 4, cloth 5, convex surface 501, concave surface 502, lever 6, spring 7, piston rod 8, piston 9, cylinder body 10 , Holder seat 11, cover plate 12, collection box 13.

[0022] The embodiment is basically as figure 1 Shown: a kind of method for cutting glass of the present invention, comprises the steps:

[0023] Step 1. Prepare the glass cutting device. The glass cutting device includes a motor, a pair of support frames 1 and a pair of rotary cylinders 2. The support frames 1 are arranged opposite to each other. The inside of the support frame 1 is sequentially installed with a cam 3 and a push rod from bottom to top. 4 and cloth 5, the output end of the motor is connected to the cam 3, the ejector rod 4 cooperates with the cam 3, the support fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com