Preparation method of macro graphene modified electrode material

A technology of graphene modification and electrode materials, applied in battery electrodes, circuits, fuel cells, etc., can solve the problems of poor electrical conductivity of carbon felt, high cost of VRB, low chemical activity, etc., and achieve improved electrical conductivity and high power density , the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In the present embodiment, the preparation method of graphene modified carbon felt, the steps are as follows:

[0041] (1) if figure 1 As shown in (a), put a 20cm×20cm×5.5mm carbon felt on the graphite homogeneous sample stage at the bottom of the preparation chamber, and align the sample with the direction of the gas outlet at the top of the preparation chamber.

[0042] (2) Turn on the H on the preparation chamber 2 valve, clean for 2min, close H 2 Valve; further, repeat cleaning 4 times;

[0043](3) Turn on the CH on the preparation chamber 4 Valve, clean for 2min, close CH 4 Valve; further, repeat cleaning 4 times;

[0044] (4) Open the high vacuum valve on the preparation chamber, manually open the high vacuum unit, and vacuumize for 5 minutes, so that the vacuum degree in the preparation chamber is 2.5×10 -2 ~3×10 -3 Pa; close the high vacuum valve and manually close the high vacuum unit;

[0045] (5) Turn on H 2 Valve, adjust the gas flow rate to 150-200...

Embodiment 2

[0054] The difference from Example 1 is:

[0055] 1. In step (7), the time for preparing graphene-modified carbon felt by chemical vapor deposition is 10 minutes.

[0056] 2. The remaining same steps of Example 1 were used to prepare graphene-modified carbon felt, and the graphene loading on the graphene-modified carbon felt was 0.6wt%.

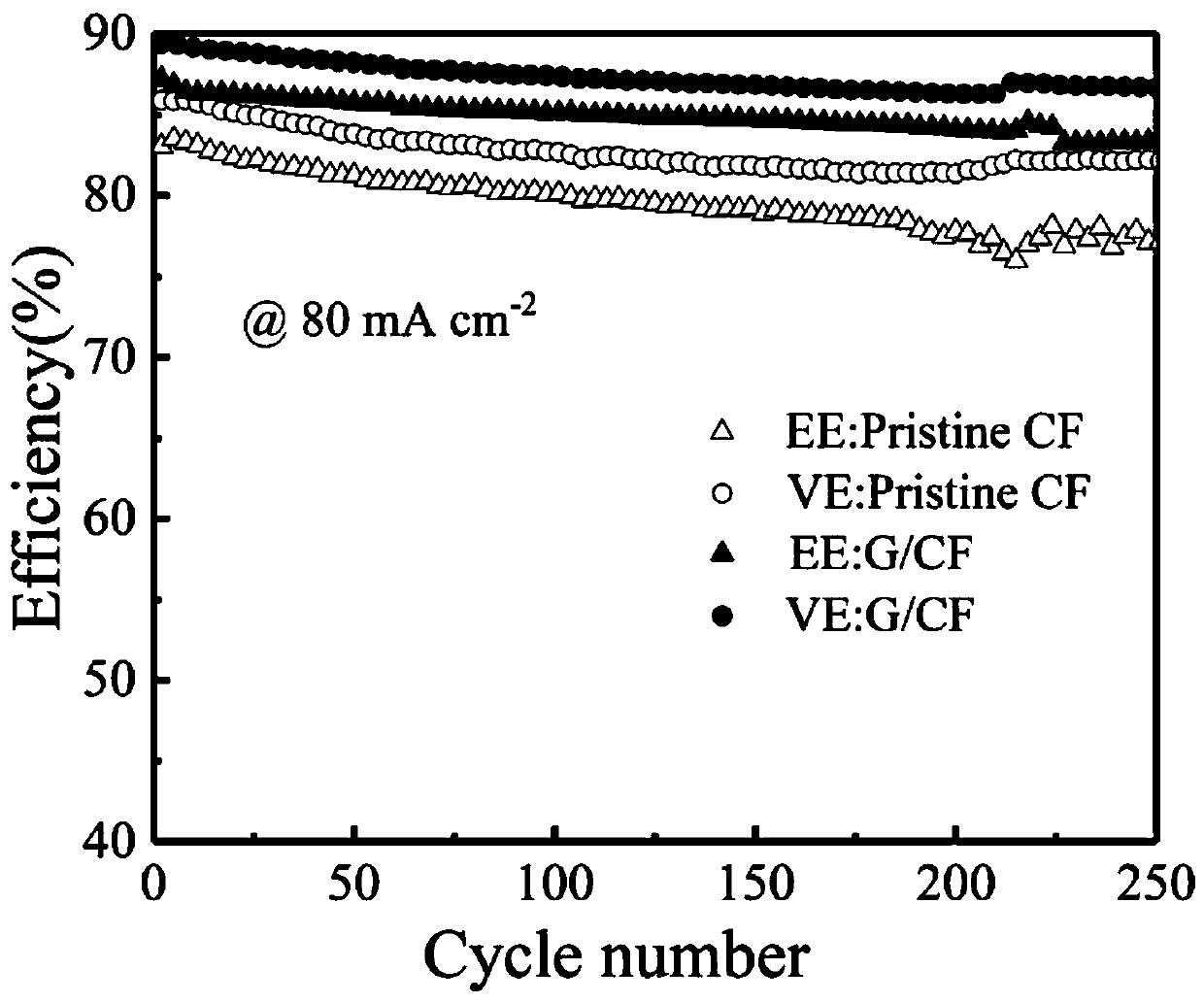

[0057] Due to the increase of the graphene deposition time, under the same conditions, the graphene load on the modified electrode increases, so the conductivity of the composite electrode is improved, which is higher than that of Example 1. Therefore, the internal resistance of the modified electrode in the all-vanadium redox flow battery is measured at room temperature to be 0.55Ω·cm 2 , the surface resistance of the composite electrode prepared at this ratio is lower than that of the original carbon felt (0.72Ω·cm 2 ), the battery energy efficiency in VRB is higher than that of pristine carbon felt, see figure 2 . Such as figure 1 As...

Embodiment 3

[0059] The difference from Example 1 is:

[0060] 1. In step (7), the time for preparing graphene-modified carbon felt by chemical vapor deposition is 15 minutes.

[0061] 2. The remaining same steps of Example 1 were used to prepare graphene-modified carbon felt, and the graphene loading on the graphene-modified carbon felt was 0.8wt%.

[0062] Due to the increase of the graphene deposition time, under the same conditions, the graphene load on the modified electrode increases, so the conductivity of the composite electrode is improved, which is higher than that of Examples 1 and 2. However, due to the increase of graphene loading, agglomeration occurs on the carbon fiber surface of the carbon felt, which affects the performance of the modified carbon felt in the vanadium battery. At the same time, due to the long deposition time, the cost of carbon felt preparation is increased, which is not conducive to the industrialization of vanadium batteries.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com