Electrolyte for wide temperature aluminum electrolytic capacitor and preparation method thereof

A technology for aluminum electrolytic capacitors and electrolytes, applied in electrolytic capacitors, liquid electrolytic capacitors, capacitors, etc., can solve the problems that it is difficult to meet the high temperature and wide temperature performance of capacitors, reduce leakage current, increase solubility, and enhance solvation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

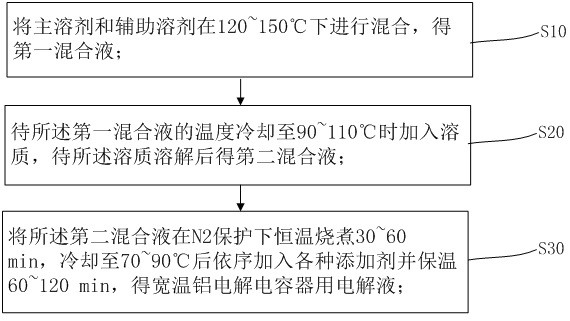

[0023] In this embodiment, an electrolyte solution for a wide temperature aluminum electrolytic capacitor and a preparation method thereof are provided, such as figure 1 As shown, it includes the following steps: S10 mixing the main solvent and the auxiliary solvent at 120-150° C. to obtain a first mixed solution. S20 Adding a solute when the temperature of the first mixed solution is cooled to 90-110° C., and obtaining a second mixed solution after the solute is dissolved. And S30 puts the second mixed solution in N 2 Cook at constant temperature under protection for 30-60 minutes, cool to 70-90°C, add various additives in sequence and keep warm for 60-120 minutes to obtain the electrolyte for wide-temperature aluminum electrolytic capacitors.

[0024] The auxiliary solvent in the step S10 is an alkoxylated sulfolane. The alkoxy chain sulfolane is preferably 3,4-dialkoxy sulfolane. The 3,4-dialkoxy sulfolane has high stability in acidic and alkaline environments due to its...

Embodiment 1

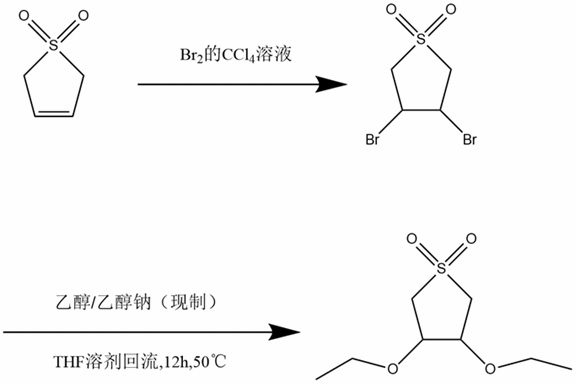

[0029] Add 3-sulfolene to bromine carbon tetrachloride to generate 3,4-dibromosulfolane, after liquid separation and distillation, add a sufficient amount of ethanol / sodium ethoxide to THF, heat and reflux at 50°C for 24 h generates 3,4-diethoxysulfolane. Then evaporate THF at 70°C, remove ethanol at 80°C, and separate 3,4-diethoxysulfolane at 200°C.

[0030]The electrolyte solution for wide-temperature aluminum electrolytic capacitors was prepared according to the following mass fractions: 10% ammonium sebacate, 35% each of ethylene glycol and N-N dimethylformamide, 5% 3-methoxypropionitrile, 3, 4-diethoxysulfolane 5%, nano silicon dioxide 4%, ammonium dihydrogen phosphate 2%, p-nitrobenzoic acid 0.5%, alkyl phosphate 2%, mannitol 1%, 8-hydroxyquinoline 0.5 %.

[0031] Mix the main solvent and auxiliary solvent at 150°C, add the solute when the temperature is cooled to 95°C, and put the solution under N 2 Boil at constant temperature under protection for 50 minutes, cool t...

Embodiment 2

[0033] Add 3-sulfolene to bromine carbon tetrachloride to generate 3,4-dibromosulfolane, after liquid separation and distillation, add a sufficient amount of ethanol / sodium ethoxide to THF, heat and reflux at 50°C for 24 h generates 3,4-diethoxysulfolane. Then evaporate THF at 70°C, remove ethanol at 80°C, and separate 3,4-diethoxysulfolane at 200°C. The synthetic route is as follows figure 2 shown.

[0034] The electrolyte solution for wide-temperature aluminum electrolytic capacitors was prepared according to the following mass fractions: 10% ammonium sebacate, 30% each of ethylene glycol and N-N dimethylformamide, 5% 3-methoxypropionitrile, 3, 4-diethoxysulfolane 15%, nano-silica 4%, ammonium dihydrogen phosphate 2%, p-nitrobenzoic acid 0.5%, alkyl phosphate 2%, mannitol 1%, 8-hydroxyquinoline 0.5 %.

[0035] Mix the main solvent and auxiliary solvent at 150°C, add the solute when the temperature is cooled to 95°C, and put the solution under N 2 Boil at constant temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com