Process step correctness automatic detection method and system

An automatic detection and correctness technology, applied in character and pattern recognition, data processing applications, instruments, etc., can solve problems such as high cost and inability to detect process steps in real time, and achieve the effect of reducing labor costs and alleviating high costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

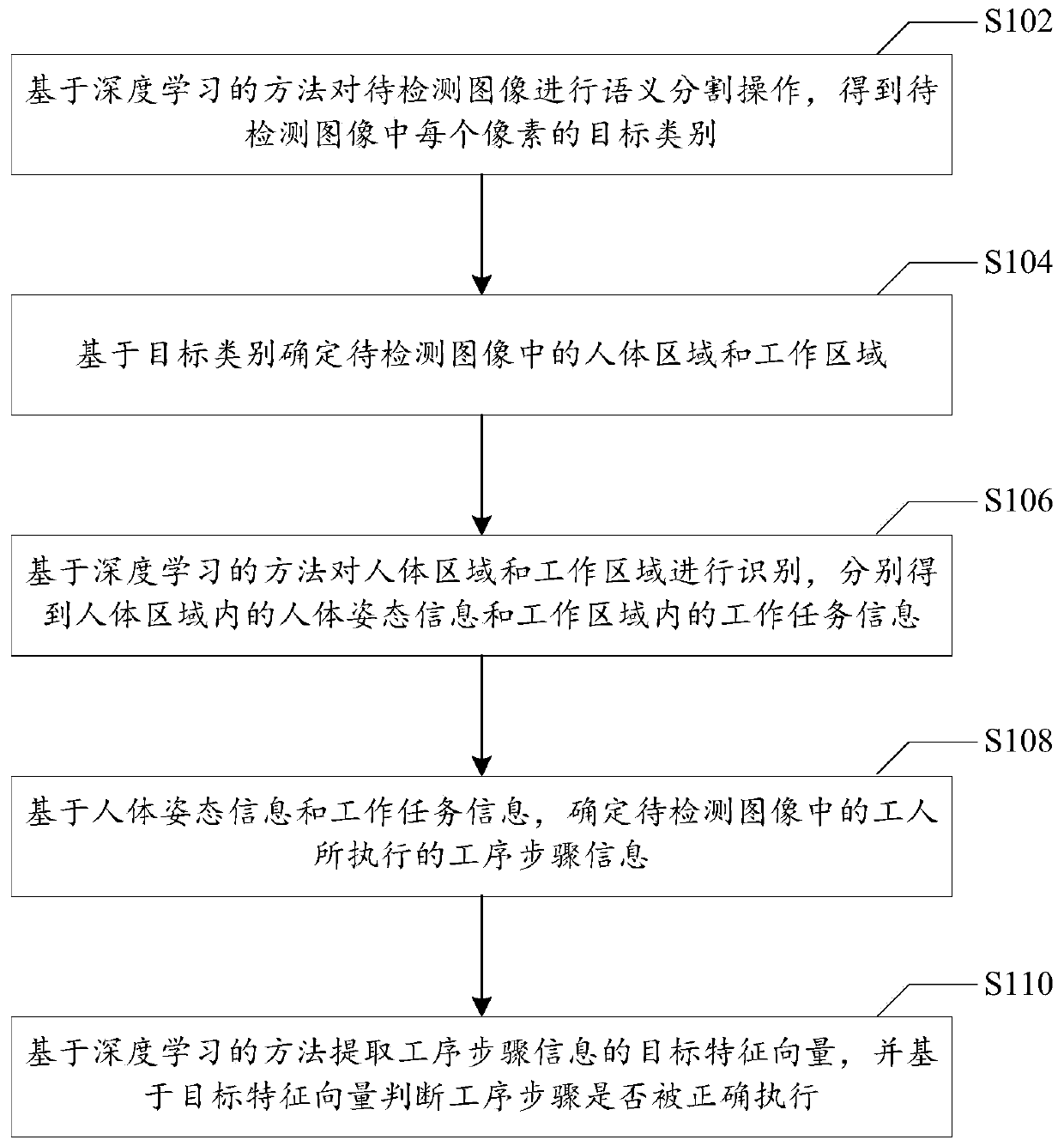

[0021] figure 1 It is a flow chart of an automatic detection method for the correctness of process steps provided according to an embodiment of the present invention, and the method is applied to a server. Such as figure 1 As shown, the method specifically includes the following steps:

[0022] Step S102, perform semantic segmentation operation on the image to be detected based on the method of deep learning to obtain the target category of each pixel in the image to be detected; the image to be detected is an image frame in a video including the execution process of the process steps. Optionally, the pixel's target class includes any of the following: human body, work area, and background.

[0023] Optionally, the video of the execution process of the process steps is acquired through a dynamic image recording device. For example, video information of the process in which workers are performing process steps in a factory can be obtained through a monitor.

[0024] Optiona...

Embodiment 2

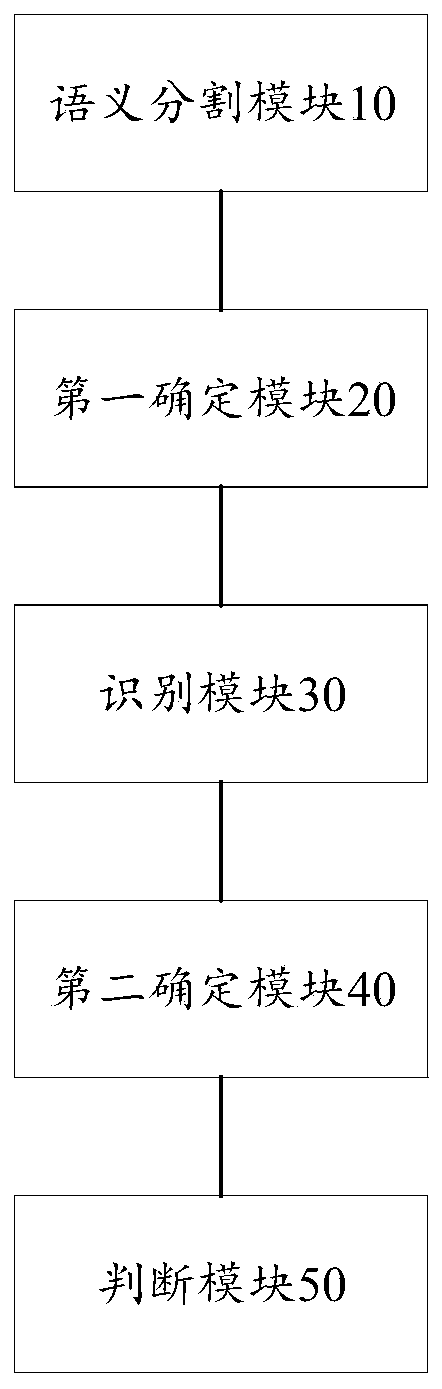

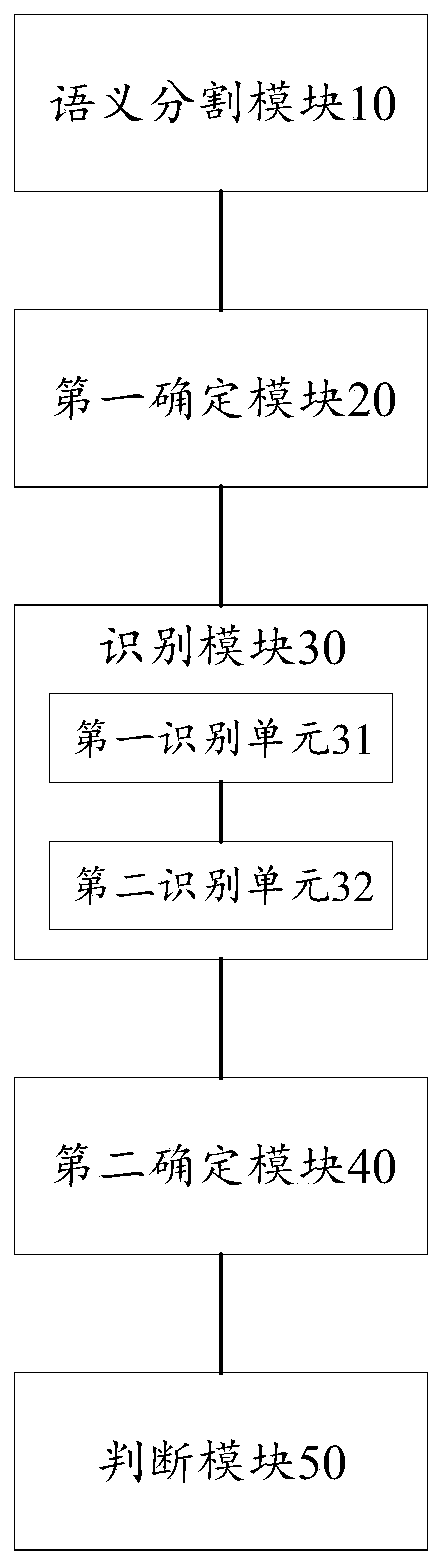

[0048] figure 2 It is a schematic diagram of an automatic detection system for process step correctness provided according to an embodiment of the present invention, and the system is applied to a server. Such as figure 2 As shown, the system includes: a semantic segmentation module 10 , a first determination module 20 , a recognition module 30 , a second determination module 40 and a judgment module 50 .

[0049] Specifically, the semantic segmentation module 10 is used to perform semantic segmentation operation on the image to be detected based on the method of deep learning, to obtain the target category of each pixel in the image to be detected; the image to be detected is an image frame in a video containing the process step execution process .

[0050] The first determining module 20 is configured to determine the human body region and the working region in the image to be detected based on the target category.

[0051] The identification module 30 is configured to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com