Environment-friendly arc extinguishing gas rapid screening method based on one-dimensional arc model

A screening method and an environmentally friendly technology, applied in the field of plasma, can solve problems such as high cost, time-consuming, and inability to effectively apply search, achieve excellent arc extinguishing performance, and overcome complex and time-consuming calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solutions and beneficial effects of the present invention will be described in detail below with reference to the accompanying drawings.

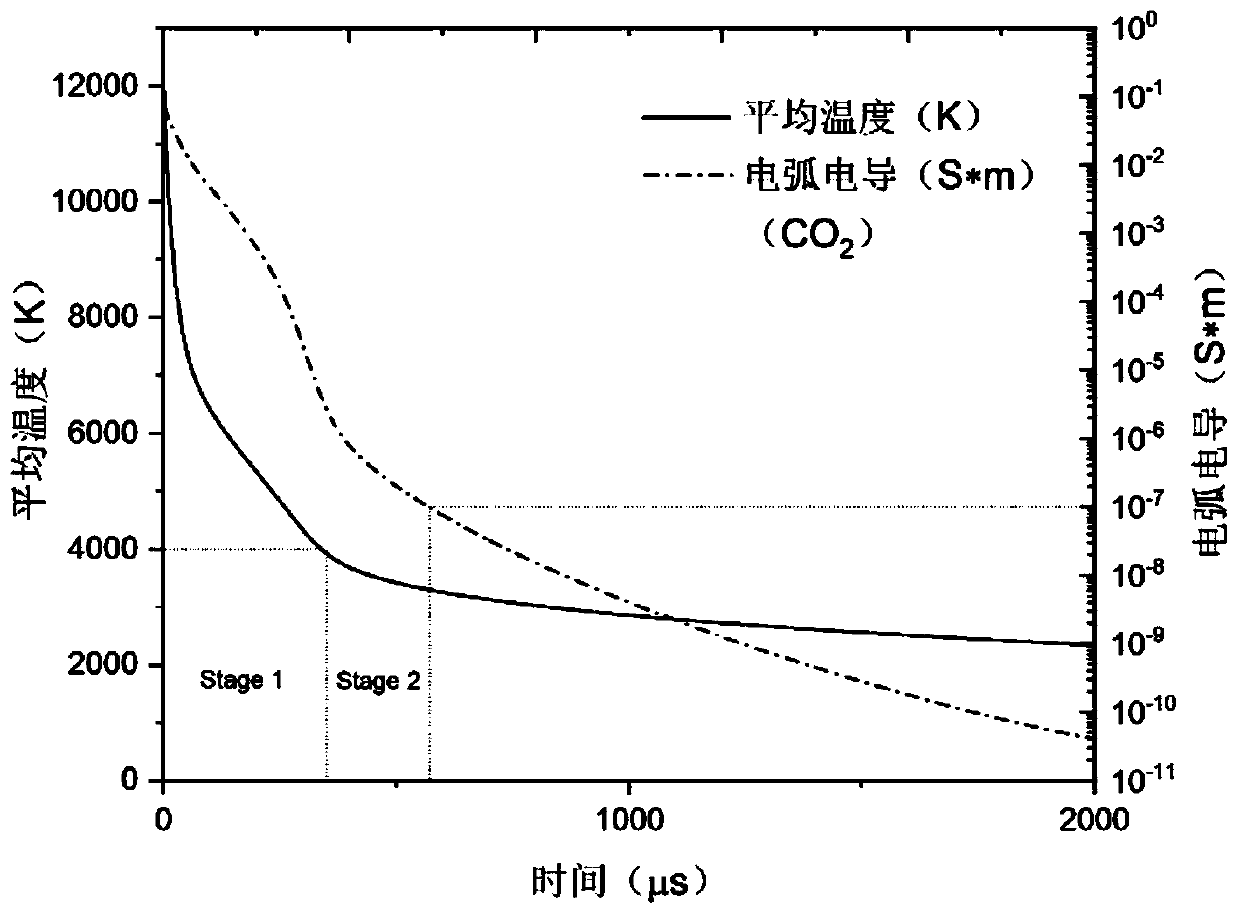

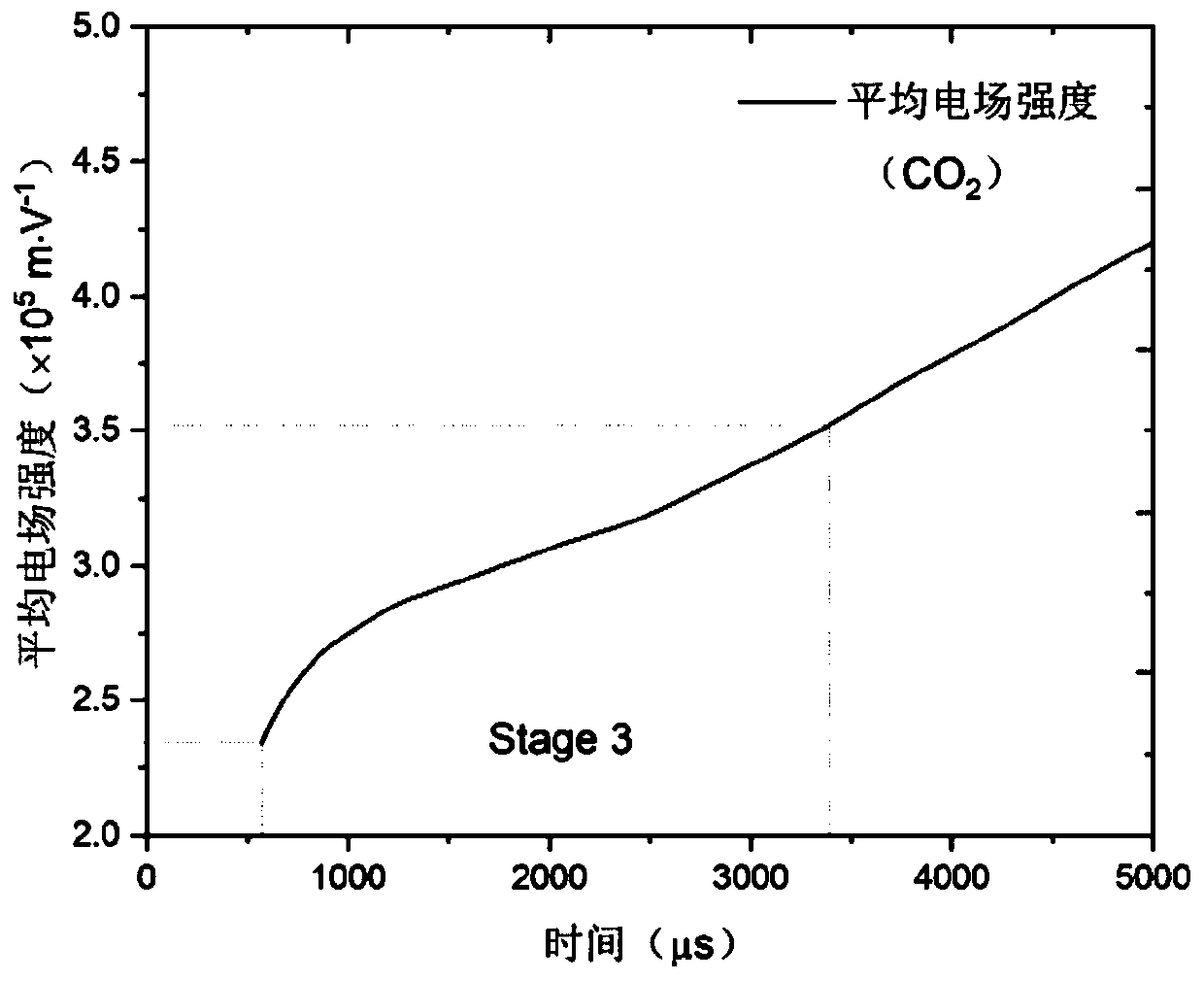

[0049] In this embodiment, the SF 6 , CO 2 , CF 4 Four gases and air were used as candidate gases to compare the arc extinguishing performance of these four gases. These four gases are selected as the research objects because they have stable properties, can be used as arc extinguishing gases, and have engineering applications. Therefore, taking these four gases as the research objects is not only representative, but also the comparison results are useful for engineering. The selection of arc extinguishing gas has certain guiding significance.

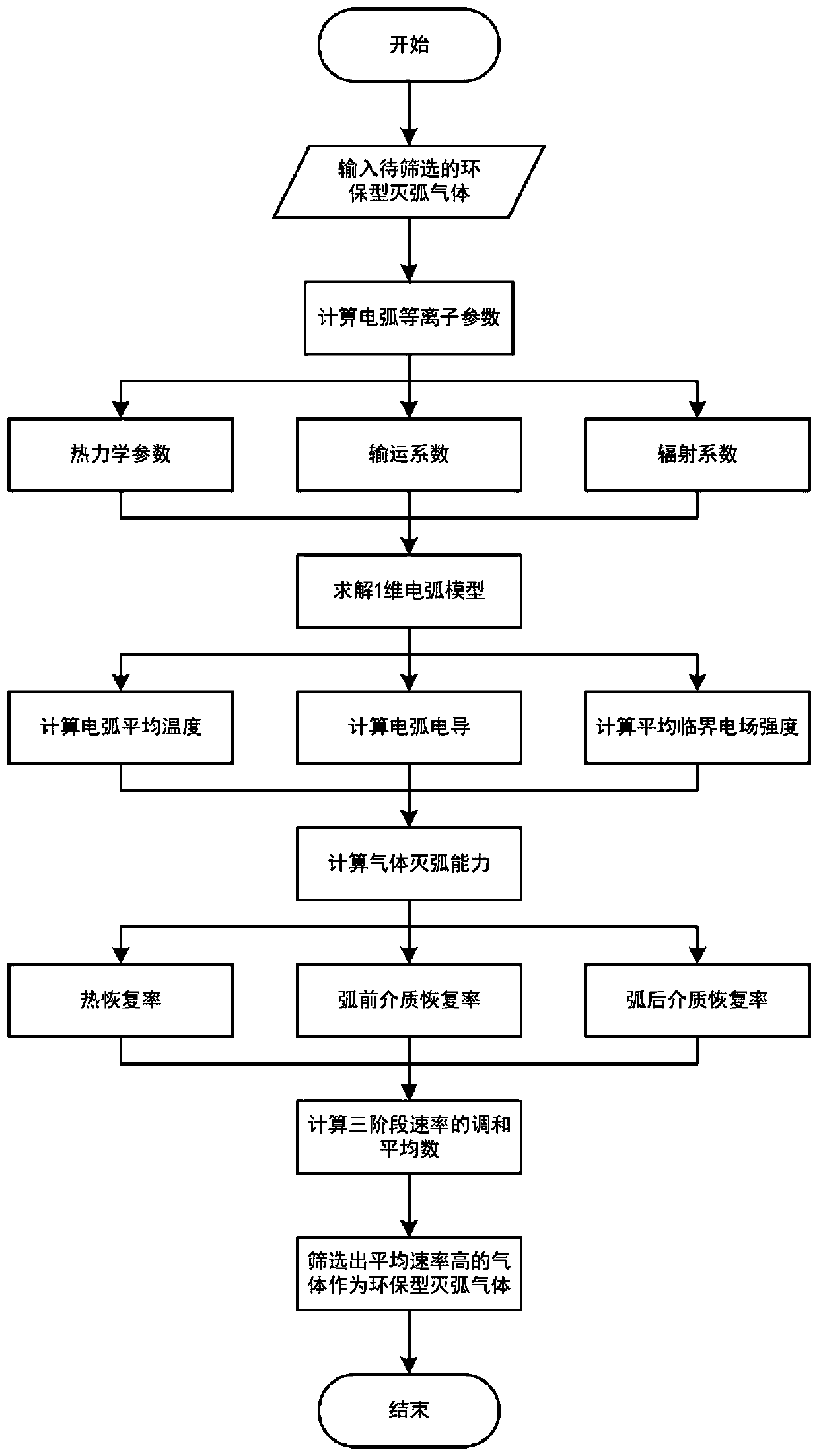

[0050] See figure 1 , which shows a flow chart of a gas arc extinguishing performance evaluation method based on a 1-dimensional arc model, and the method includes the following steps:

[0051] (1) Calculate arc plasma thermodynamic parameters, including mass density, speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com