Temperature-insensitive elliptical hinge fiber Bragg grating acceleration sensor

An acceleration sensor, fiber grating technology, applied in the direction of velocity/acceleration/shock measurement, acceleration measurement, acceleration measurement using inertial force, etc., can solve the problems of increasing the difficulty of signal detection, large volume and weight, low natural frequency, etc. Achieve the effect of reducing the overall packaging process, multiplying the sensitivity, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention and its beneficial effects will be clearer and clearer by further describing the specific embodiments of the present invention in conjunction with the accompanying drawings of the specification; and it is intended to explain the present invention and not be construed as a limitation of the present invention.

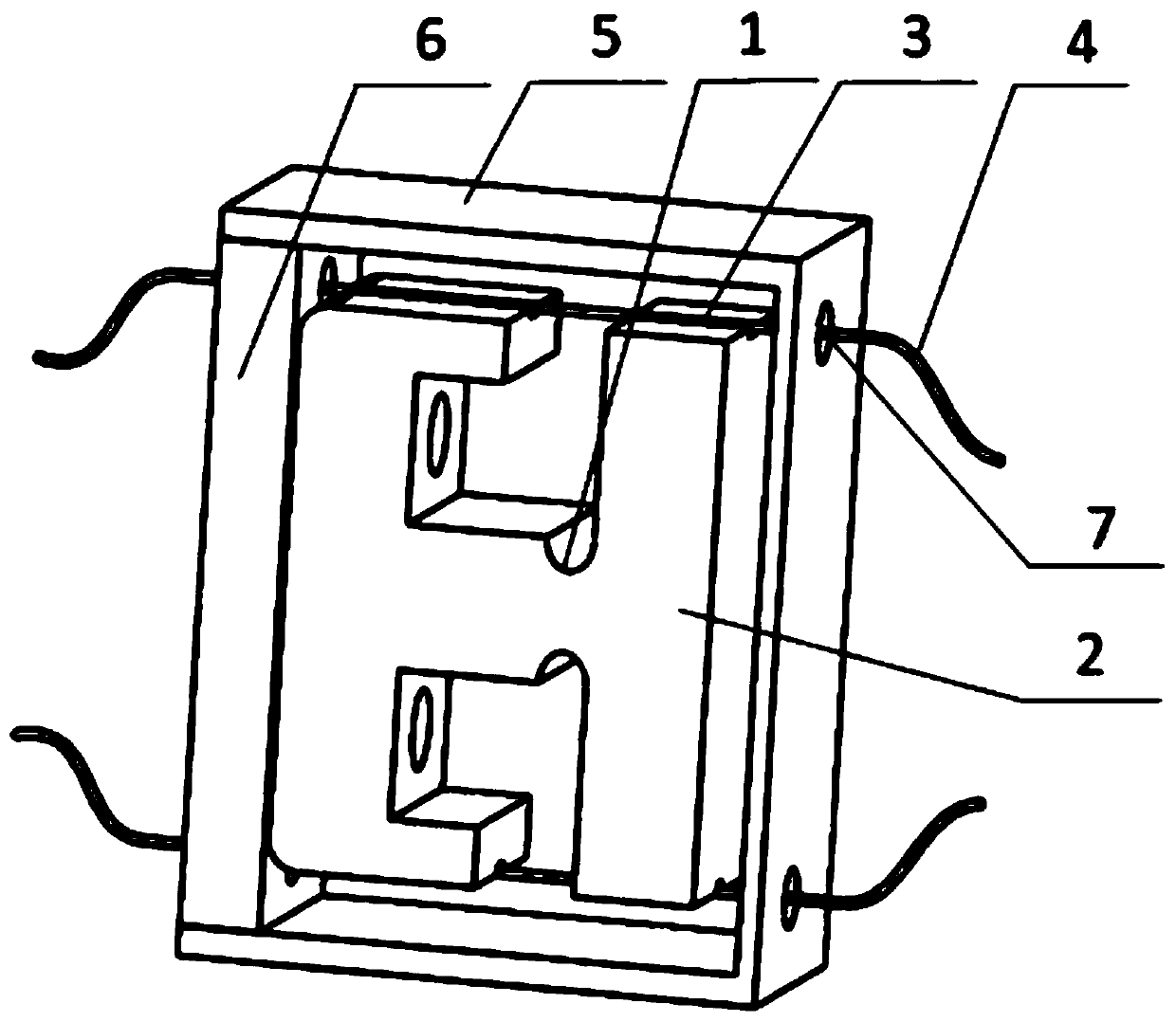

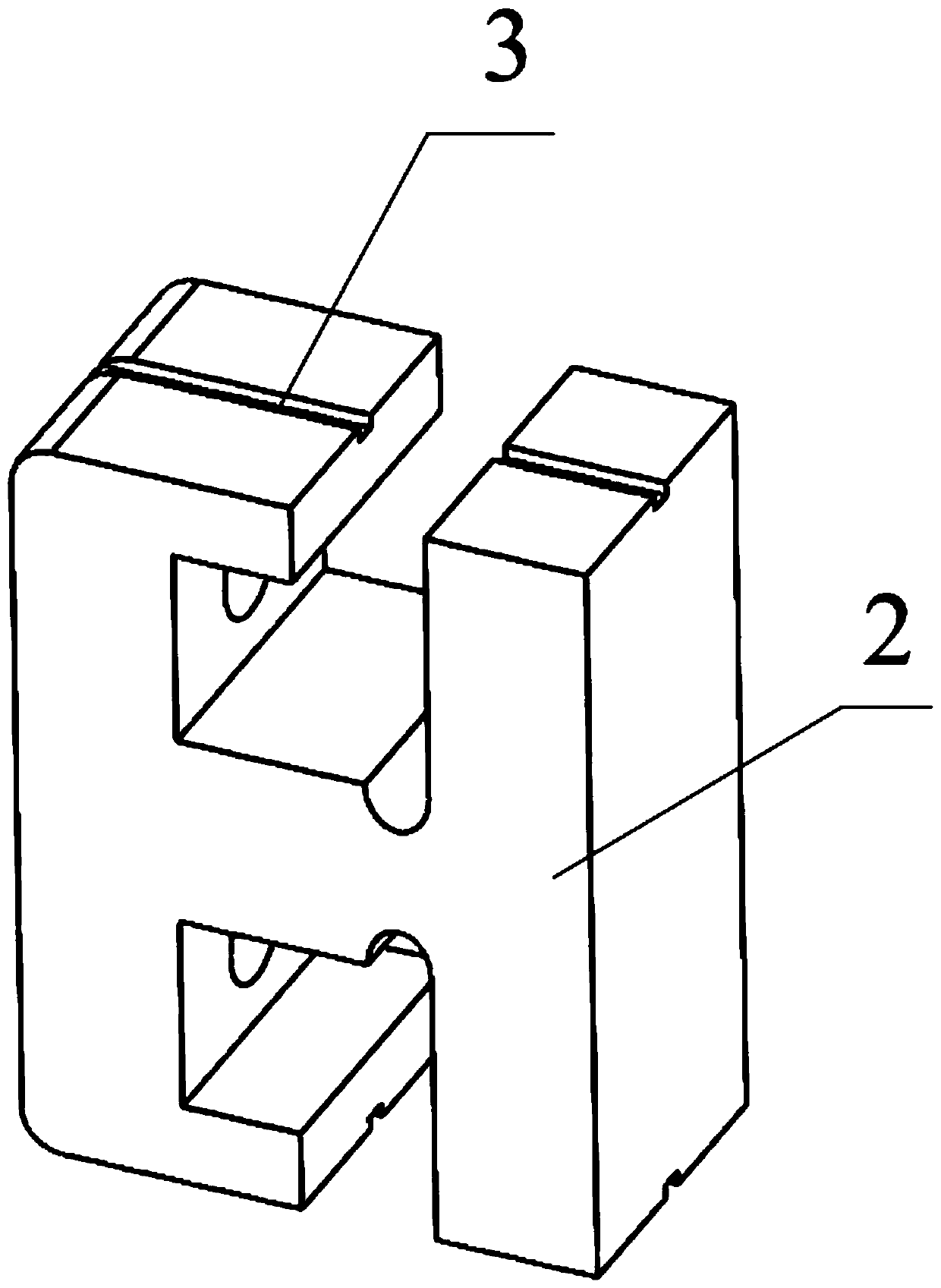

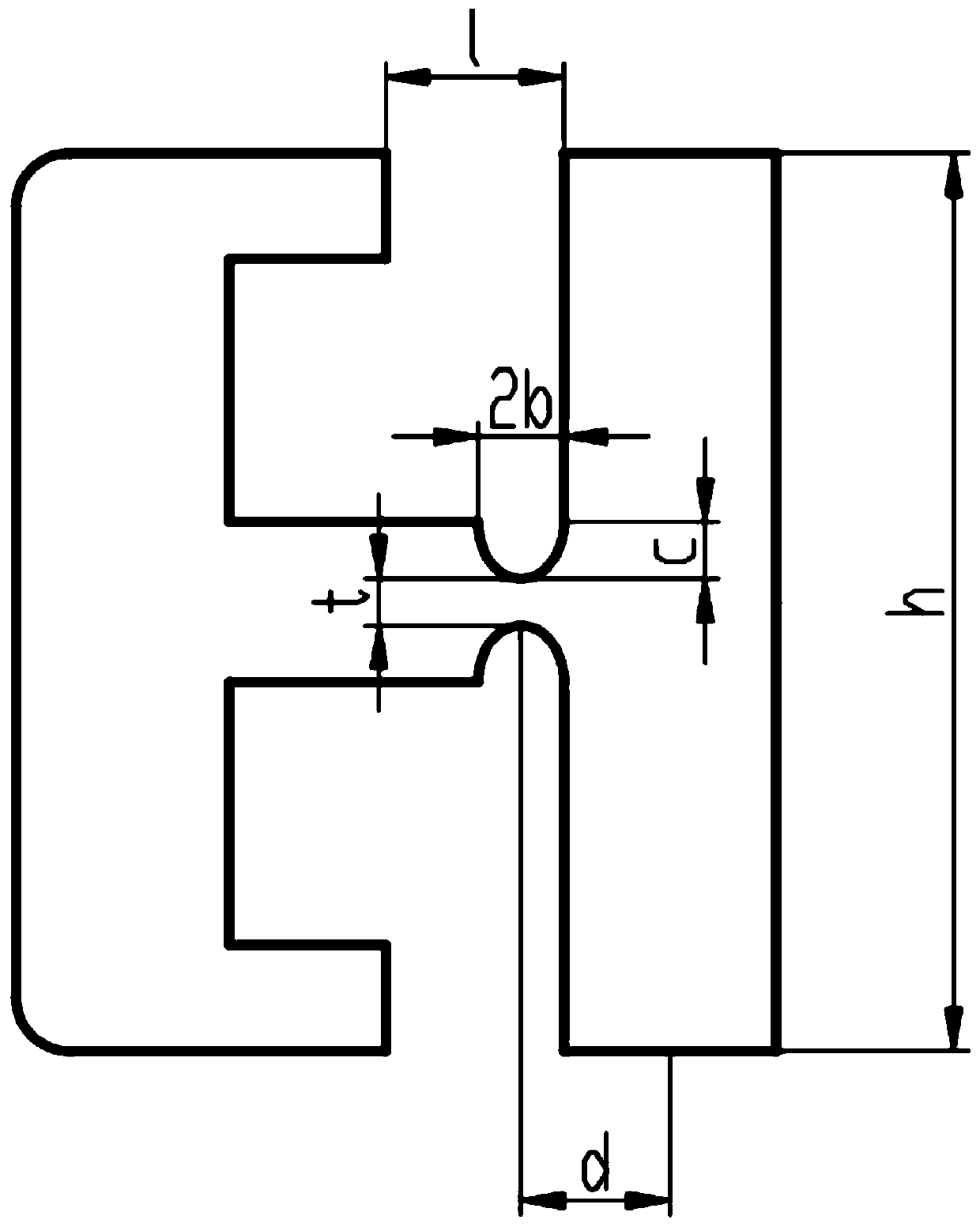

[0024] refer to Figure 1-4 As shown, the embodiment of the present invention preferably provides a temperature-insensitive elliptical hinge fiber grating acceleration sensor, including a sensor housing 5, a core body and two optical fibers 4, and the core body includes an inertial mass 2, The elliptical flexible hinge 1 and the inertial mass 2 are symmetrical with respect to the flexible hinge and are higher than the other side connected by the flexible hinge to achieve sensitivity enhancement. The inertial mass 2 and the upper and lower tops of the base opposite to it are provided with optical fiber grooves 3, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Center wavelength | aaaaa | aaaaa |

| Thin wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com