Fuel cell test system pipeline air tightness pressure maintaining test platform

A test system, fuel cell technology, applied in liquid tightness measurement using liquid/vacuum degree, fluid tightness test, machine/structural component test, etc., can solve unfavorable pipeline continuity test and low test accuracy , can not be displayed in real time and other problems, to achieve the effect of accurate and reliable test results, convenient pipeline connection, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

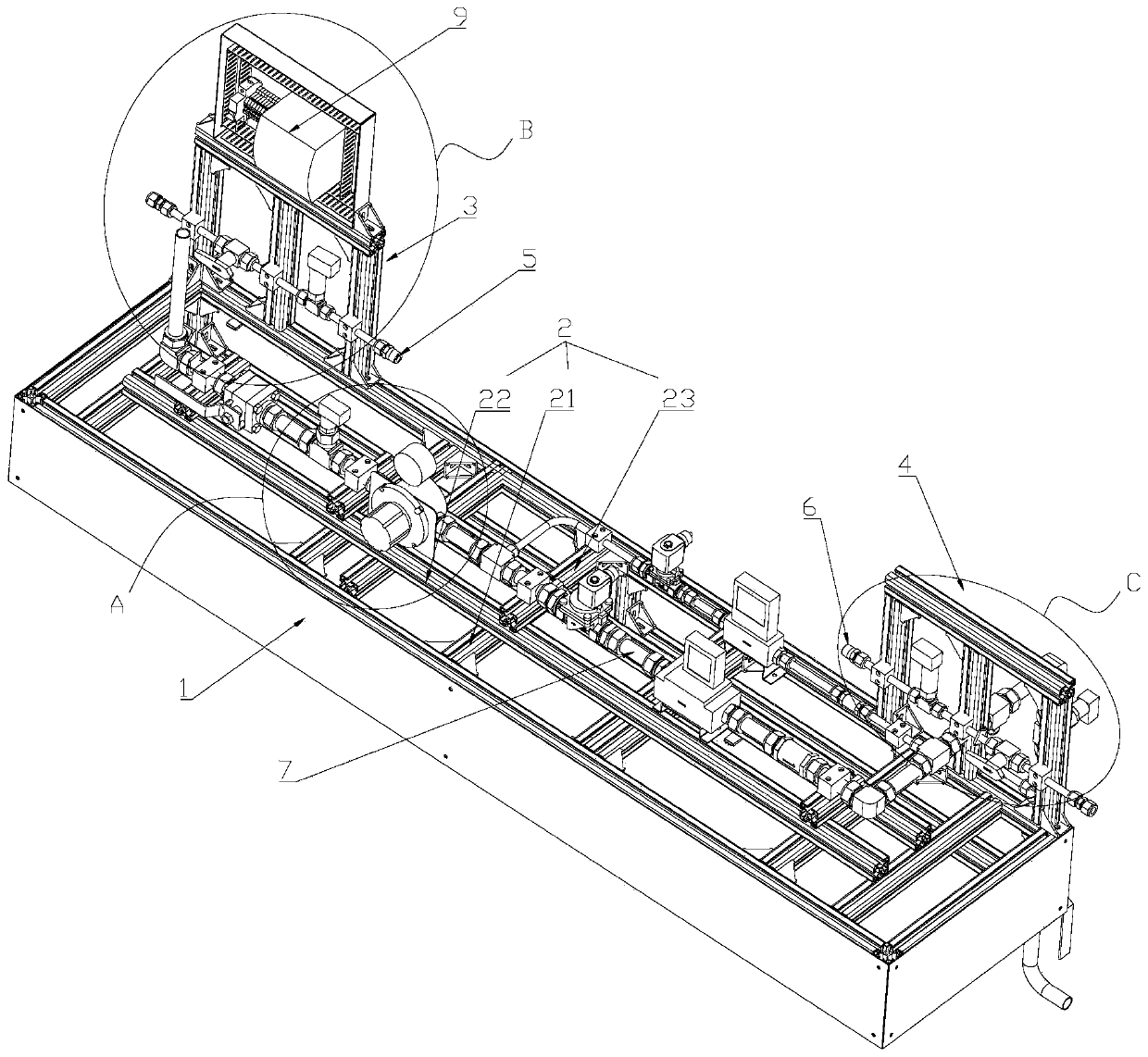

[0033] Such as figure 1 As shown, this embodiment provides a fuel cell test system pipeline airtightness pressure-holding test platform, including a base 1, the base 1 is a cylindrical structure with a hollow rectangular cross-section that penetrates up and down and is closed on the sides surrounded by four plates. . The four boards can be made of aluminum or wood, the aluminum can be fixed by welding, and the wood can be fixed by hinges or mortise and tenon structures. The upper surface of the base 1 can be covered with a layer of panels. In order to make the test platform light and easy to manufacture, the present embodiment adopts a structure that penetrates up and down.

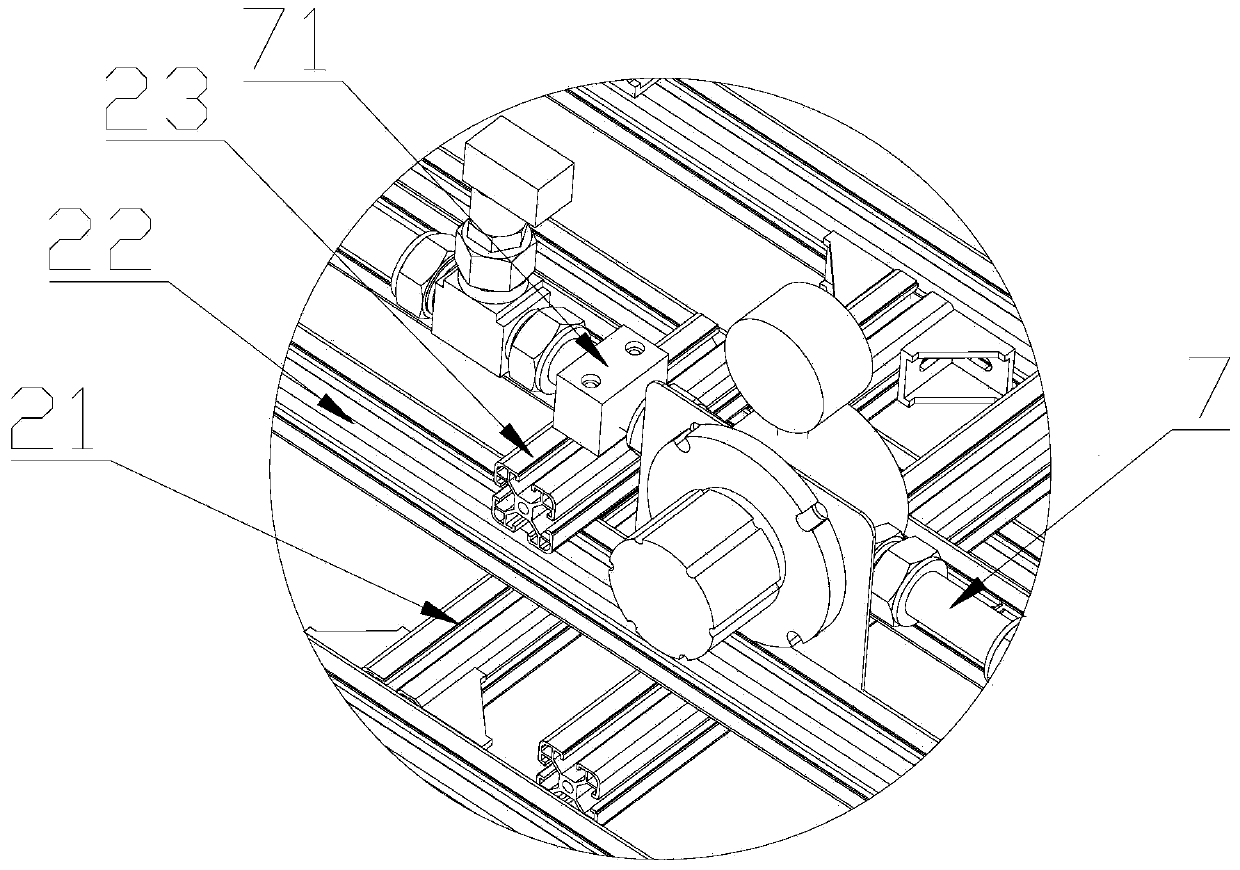

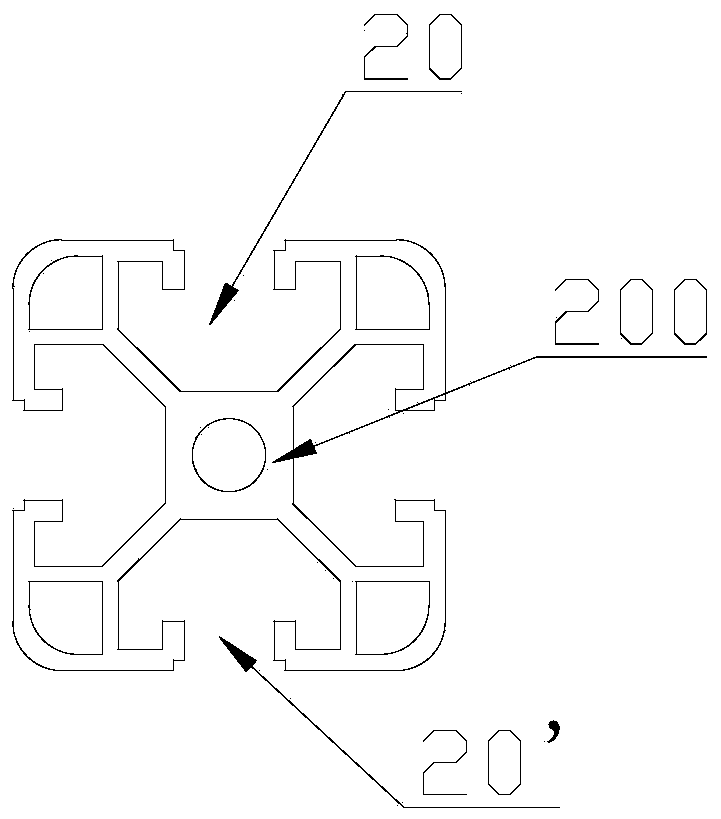

[0034] On the base 1 are fixed a first bracket 2, a second bracket 3, a third bracket 4, a front air intake pipeline 5, and a rear exhaust pipeline 6; The air pipeline 5 and the rear exhaust pipeline 6 are respectively fixed on the second support 3 and the third support 4, and the pipeline 7 to be teste...

Embodiment 2

[0050] Such as Figure 5 As shown, in this embodiment, on the basis of Embodiment 1, the power supply 9 is fixed on the second support 3 or the third support 4, so as to facilitate the overall movement of the test platform. The power supply 9 in this embodiment is a DC24V power supply 9 with an input of 220V and an output of 24V. If it is fixed on the outer side, the outer side of the pole 31 needs to be provided with a vertical chute 311, the power supply 9 is provided with a skirt, and the skirt is provided with a screw hole, and the bolt 81 passes through the screw hole of the power supply 9 and the limit The nut 82 in the vertical slide groove 311 outside the vertical bar is screwed and fixed. If it is fixed on the top surface, it is necessary to connect a plurality of upright bars 31 by another cross bar 32, and then fix the power supply 9 and the cross bar 32 by the same method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com