Manufacturing method of flexible temperature sensor

A technology of temperature sensor and manufacturing method, which is applied in the field of flexible sensors, can solve the problems of large hysteresis, the inability of flexible temperature sensors to undergo high-temperature annealing, and failure to achieve high performance, and achieve stable and reliable performance, excellent measurement performance, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

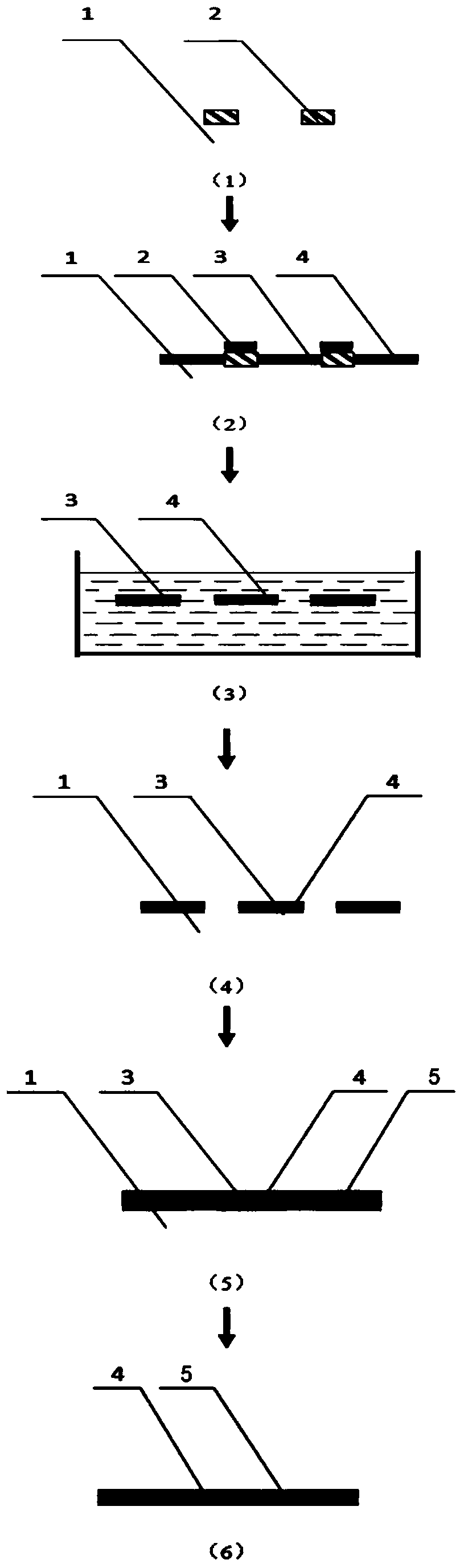

[0036] Such as figure 1 As shown, this embodiment provides a method for manufacturing a flexible temperature sensor, comprising the following steps:

[0037] Step 1. Select a double-sided polished silicon wafer as the substrate, place the silicon wafer in acetone, ethanol and deionized water in sequence for ultrasonic cleaning, and dry after cleaning. Preferably, the cleaning time is 5 minutes;

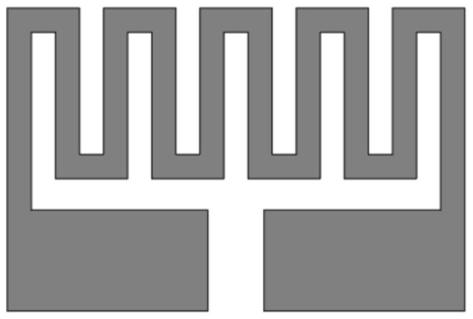

[0038] Step 2. Spin-coat a layer of photoresist 2 on the silicon substrate 1 at a spin-coating speed of 1000 rpm for 12 seconds, then 4000 rpm for 40 seconds; , 3min), exposure (21s), post-baking (100°C, 3min), development (20s) and other operations, a three-dimensional figure serpentine structure is formed;

[0039] Step 3, after forming by photolithography, sputter deposit a layer of sacrificial layer 3 and a layer of metal temperature sensitive resistor 4 on the silicon substrate 1, wherein the sacrificial layer 3 is metal chromium, and the deposition time is 5 minutes; the metal ...

Embodiment 2

[0045] Such as figure 1 As shown, this embodiment provides a method for manufacturing a flexible temperature sensor, comprising the following steps:

[0046] Step 1. Select a double-sided polished silicon wafer as the substrate, place the silicon wafer in acetone, ethanol and deionized water in sequence for ultrasonic cleaning, and dry after cleaning. Preferably, the cleaning time is 5 minutes;

[0047] Step 2. Spin-coat a layer of photoresist 2 on the silicon substrate 1 at a spin-coating speed of 1000 rpm for 12 seconds, then 4000 rpm for 40 seconds; , 3min), exposure (21s), post-baking (100°C, 3min), development (20s) and other operations, a three-dimensional figure serpentine structure is formed;

[0048]Step 3, after forming by photolithography, sputter deposit a layer of sacrificial layer 3 and a layer of metal temperature sensitive resistor 4 on the silicon substrate 1, wherein the sacrificial layer 3 is metal chromium, and the deposition time is 5 minutes; the metal t...

Embodiment 3

[0054] Such as figure 1 As shown, this embodiment provides a method for manufacturing a flexible temperature sensor, comprising the following steps:

[0055] Step 1. Select a double-sided polished silicon wafer as the substrate, place the silicon wafer in acetone, ethanol and deionized water in sequence for ultrasonic cleaning, and dry after cleaning. Preferably, the cleaning time is 5 minutes;

[0056] Step 2. Spin-coat a layer of photoresist 2 on the silicon substrate 1 at a spin-coating speed of 1000 rpm for 12 seconds, then 4000 rpm for 40 seconds; , 3min), exposure (21s), post-baking (100°C, 3min), development (20s) and other operations, a three-dimensional figure serpentine structure is formed;

[0057] Step 3, after forming by photolithography, sputter deposit a layer of sacrificial layer 3 and a layer of metal temperature sensitive resistor 4 on the silicon substrate 1, wherein the sacrificial layer 3 is metal chromium, and the deposition time is 5 minutes; the metal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com