Device and method for extracting rock core by drilling fractured rock mass

A core and rock mass technology, applied in the field of geotechnical engineering, can solve the problems of single function of drilling rig, low success rate and efficiency of drilling core operation, and inability to meet the requirements of in-situ sampling, so as to improve the success rate and operation Efficiency, meeting rock mechanics experimental conditions, and reducing disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

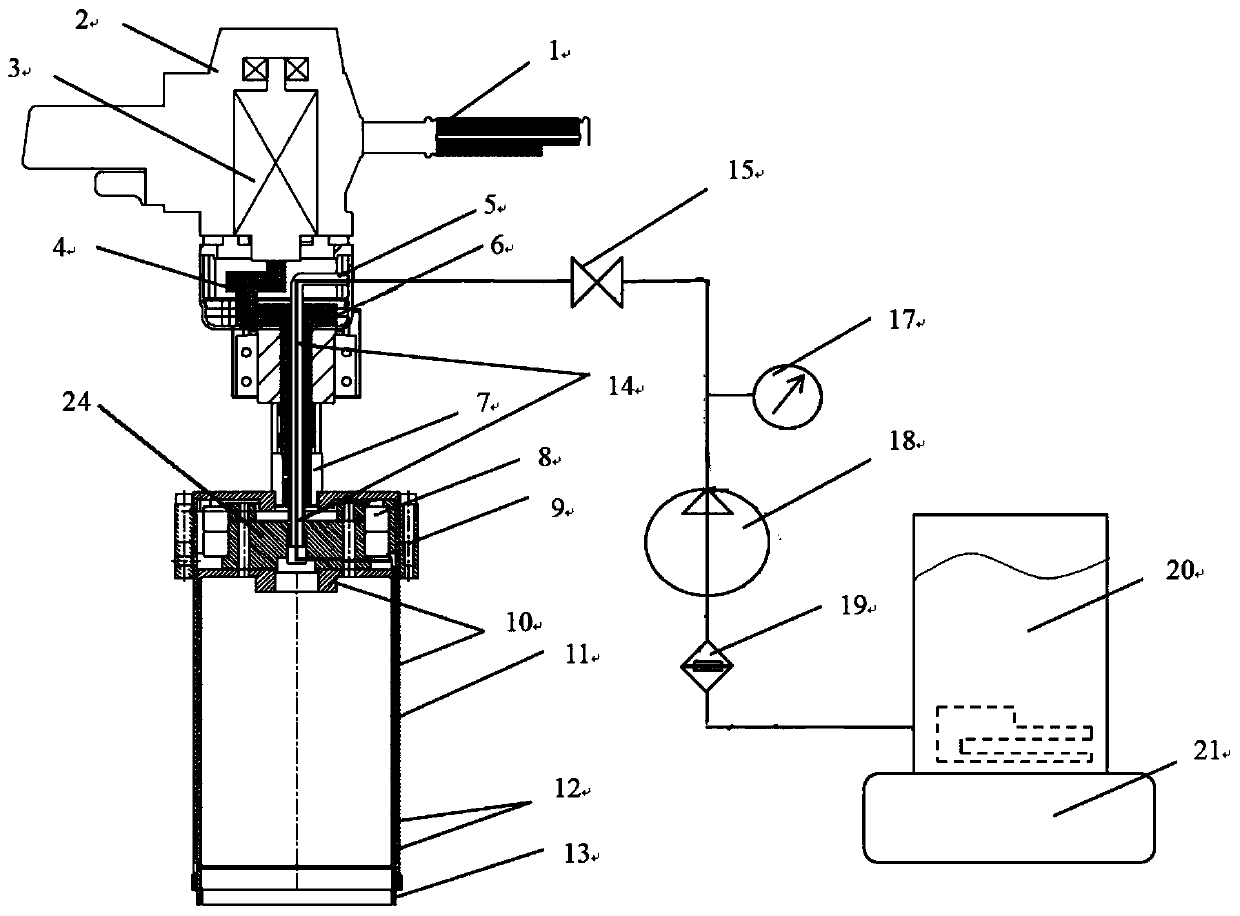

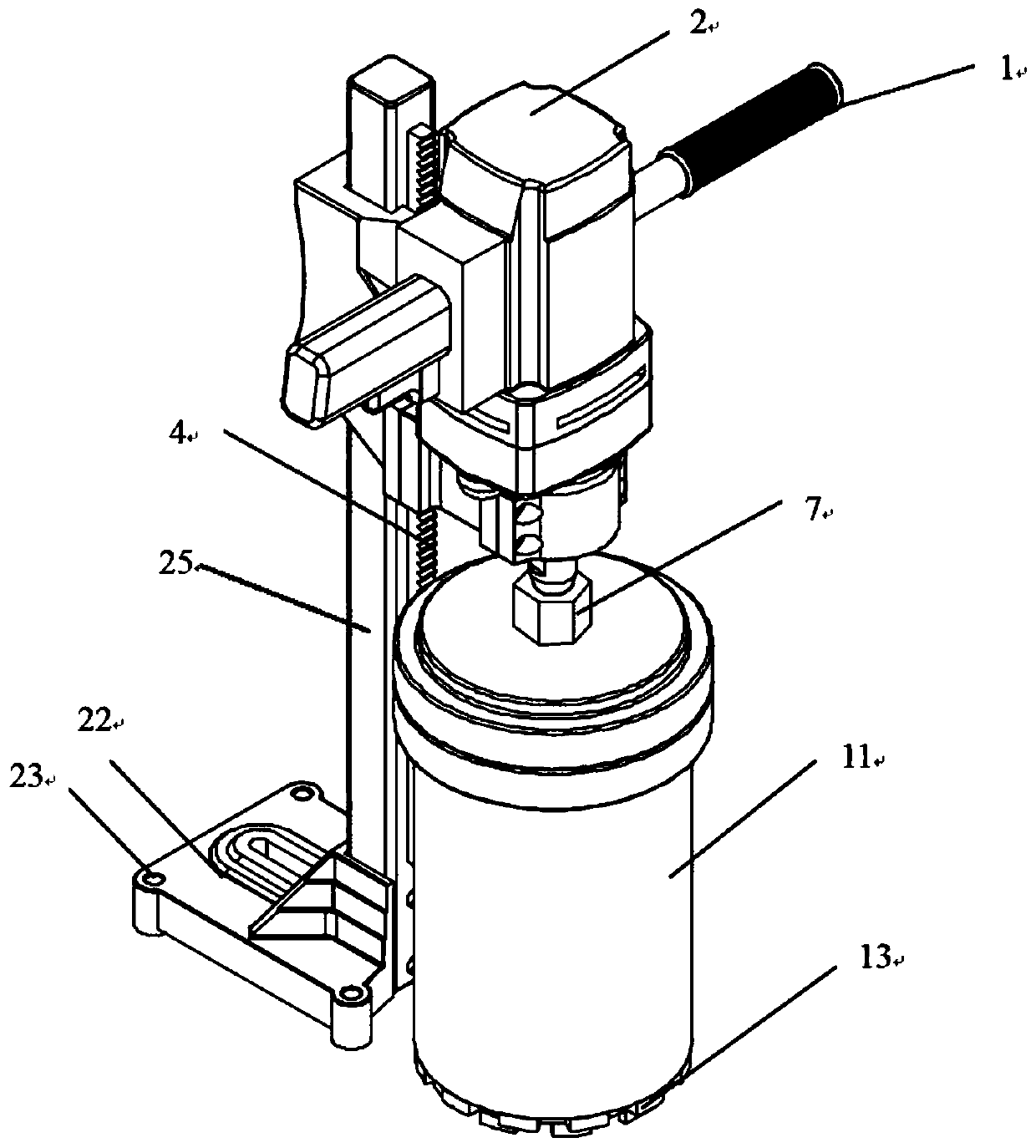

[0034] This embodiment is aimed at the fact that traditional diamond drilling rigs cannot perform core sampling operations in the broken rock mass. Each time the broken rock mass is drilled, the integrity of the core will not be guaranteed. It cannot be used. This embodiment changes the traditional method of coring the broken rock mass and provides a special sampling device. The idea of sampling the broken rock mass in this embodiment is: "Consolidate first, then sample, and finally dissolve". The method of direct wax sealing after drilling the rock core can more completely maintain the integrity of the rock core and ensure more brokenness. In-situ sampling of rock mass ensures the success rate and efficiency of core drilling operations. It is of great significance to carry out rock mechanics experiments on samples of broken and weak rock mass in the later stage.

[0035] A device for drilling broken rock masses to extract cores, comprising: a driving device, a drill bit an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com