High-frequency eccentric vibration acoustic wave power head for drilling machine

A technology of power head and eccentricity, which is used in vibration drilling, non-rotation vibration suppression, automatic control system of drilling, etc., can solve the problems of lowering the working temperature of the vibrator shaft bearing, lowering the performance requirements, poor working stability, etc., and achieves the spindle rotation. The effect of stable and reliable axial vibration movement, reducing performance requirements and improving working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

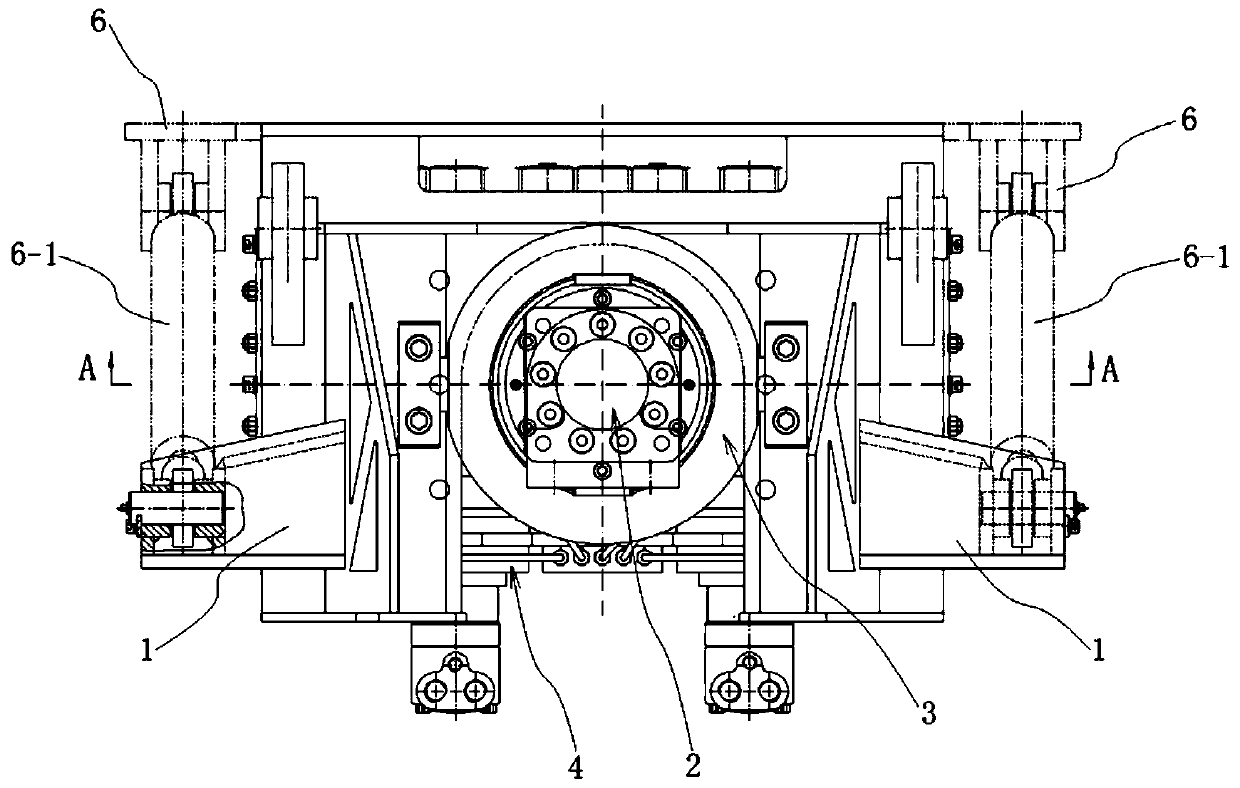

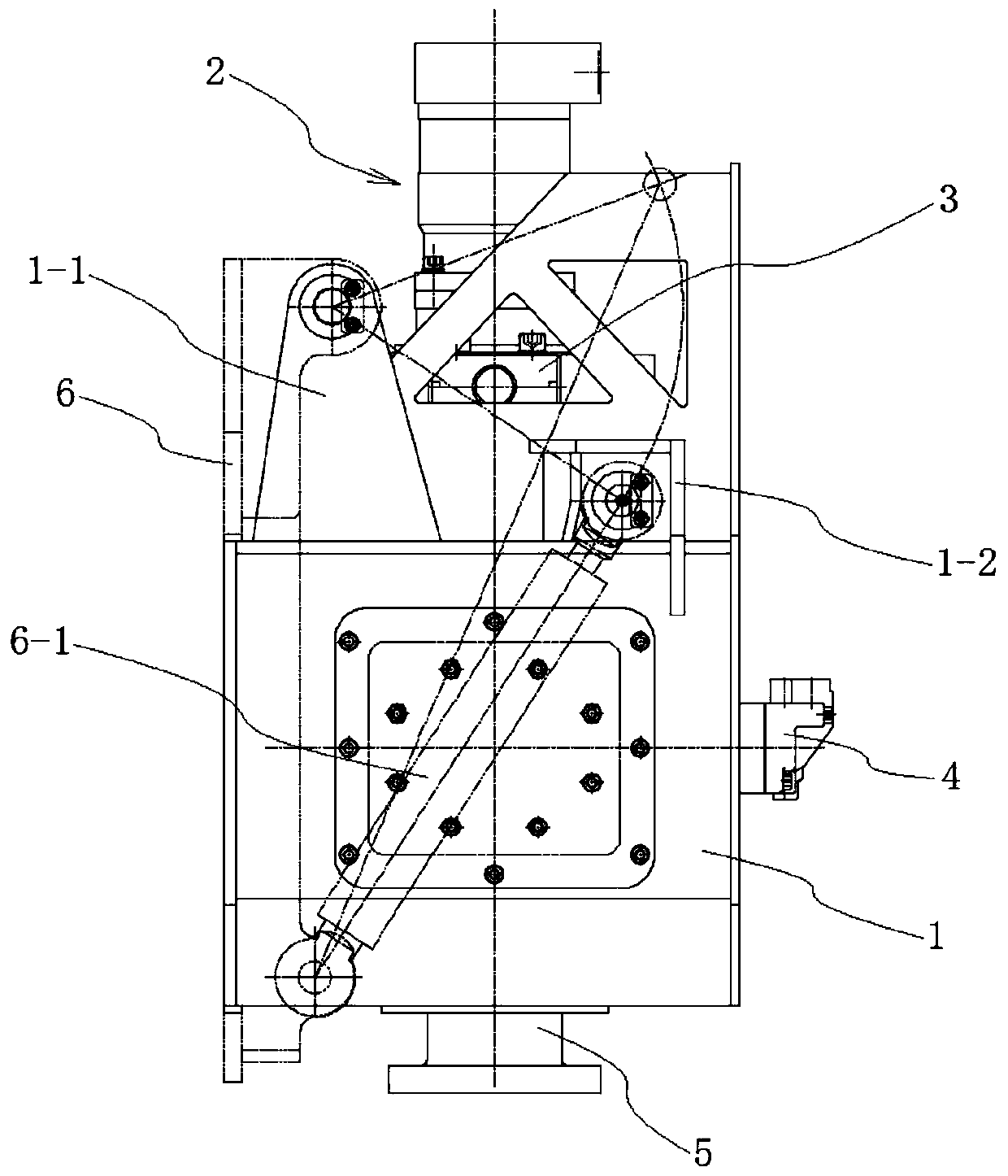

[0055] combine Figure 1 to Figure 5As shown, a high-frequency eccentric vibration acoustic wave power head for drilling rigs in this embodiment includes a main frame 1, a main shaft rotation mechanism 2, a main shaft vibration mechanism 4 and a bearing cooling and lubrication system 7, and the main frame 1 serves as a support for the entire acoustic wave power head The components are used to install the main shaft rotation mechanism 2 and the main shaft vibration mechanism 4, and the bearing cooling and lubricating system 7 is used for cooling and lubricating the bearings in the main shaft vibration mechanism 4. Wherein, the main shaft rotation mechanism 2 includes a main shaft hydraulic motor 2-1 and a main shaft 2-7, the main shaft hydraulic motor 2-1 is installed on the upper part of the main frame 1, and the output shaft of the main shaft hydraulic motor 2-1 and the main shaft 2-7 Spline structure transmission connection is used to drive the main shaft 2-7 to rotate and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com