Anti-blocking floor drain

An anti-clogging and floor drain technology, which is applied to waterway systems, climate change adaptation, drainage structures, etc., can solve problems such as floor drain blockage, achieve the effects of increasing service life, increasing use time, and speeding up cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

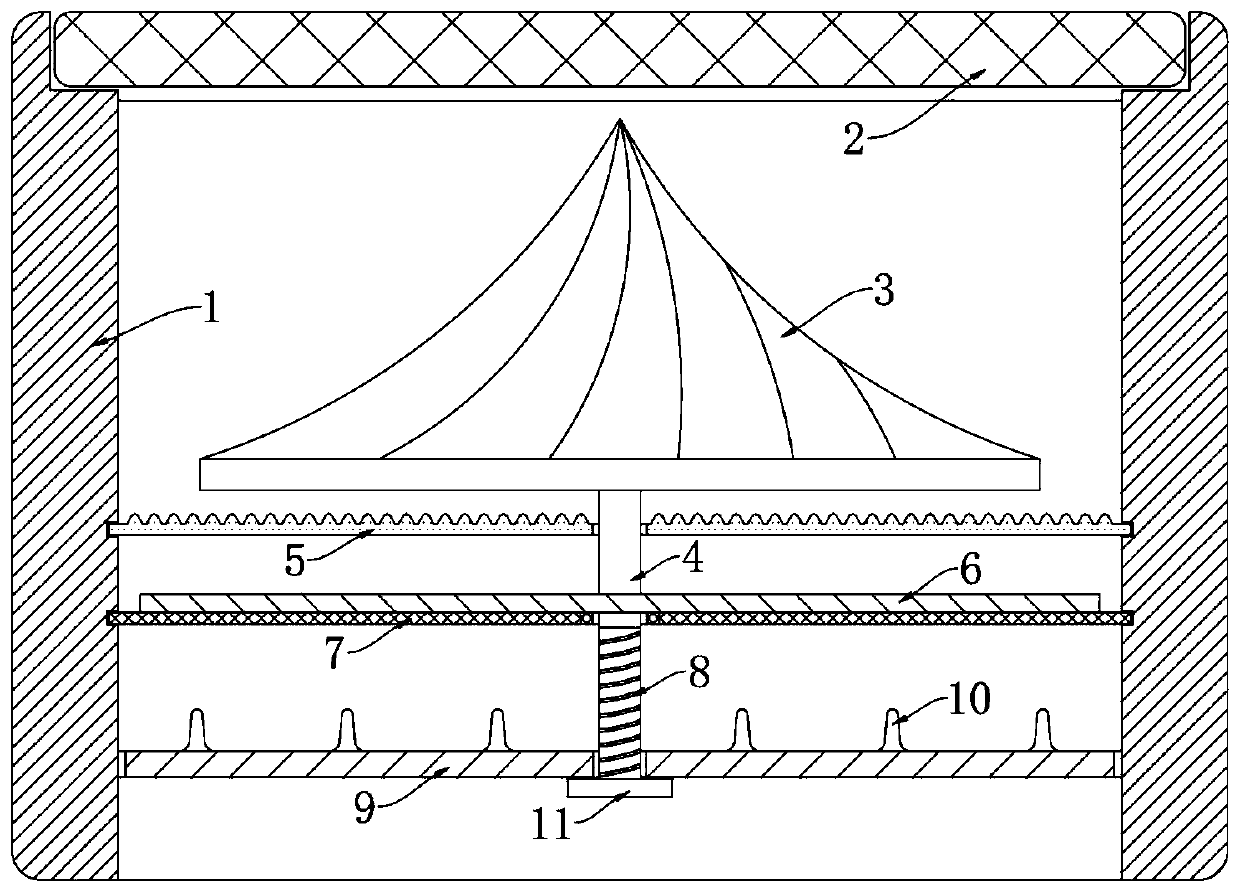

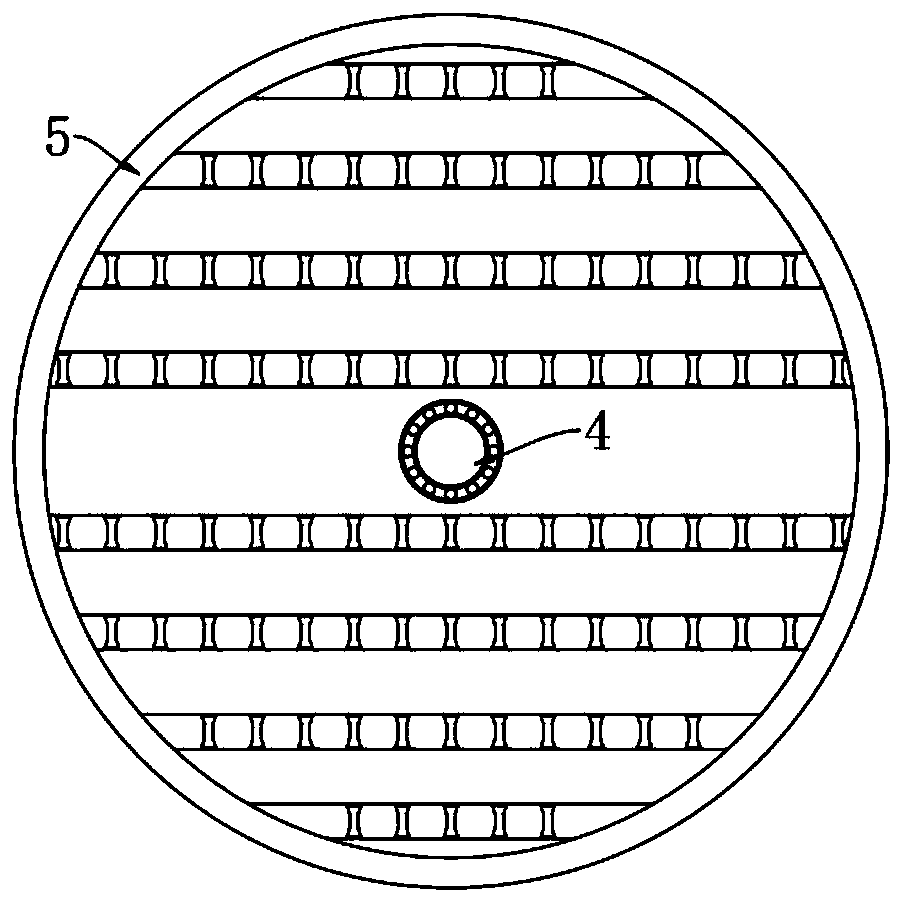

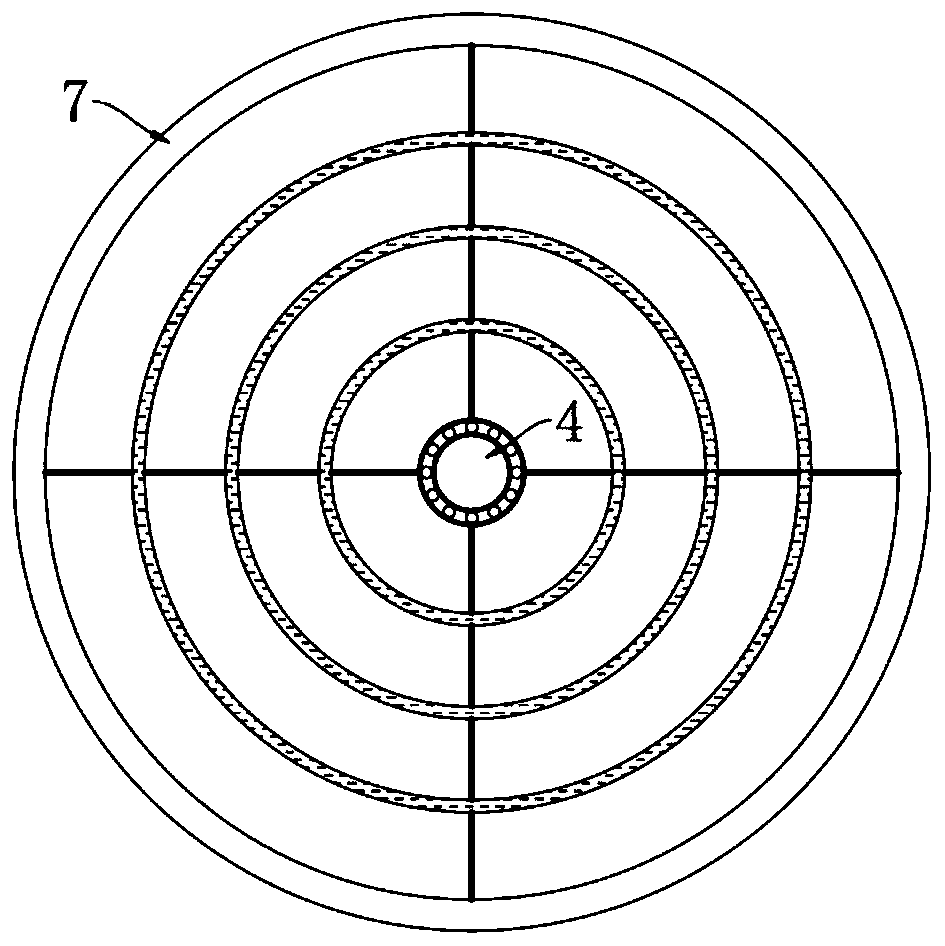

[0025] Reference Figure 1-4 , An anti-clogging floor drain, comprising a floor drain body 1 and a fine screen 2 placed on the upper end of the floor drain body 1. A sawing disc 5 and a coarse screen 7 are clamped in parallel from top to bottom in the floor drain body 1, and a sawing disc 5 A straight rod 4 is supported together with the coarse screen 7 through a bearing. The upper and lower ends of the straight rod 4 are respectively fixedly provided with a tapered block 3 and a limit plate 11, and the outer wall of the tapered block 3 is equidistantly circumferentially provided with oblique grooves. , When water flows through the tapered block 3, it will flow in the corresponding direction under the action of the chute. Under the force of the water flow, the tapered block 3 rotates, and the side wall of the straight rod 4 is provided with a thread groove 8 and the thread groove 8 Located below the coarse screen 7, the straight rod 4 is threadedly connected with a grid 9 throug...

Embodiment 2

[0034] Reference Figure 5-6 The difference between this embodiment and embodiment 1 is that: the outer side of the cone block 3 is wrapped with an antifouling layer, and a plurality of piezoelectric ceramics 19 are arranged between the antifouling layer and the cone block 3, and the antifouling layer can be coated The floor drain body 1 is made of rubber sheet covered with antifouling paint. A plurality of water storage tanks 13 are symmetrically opened in the side wall of the floor drain body 1, and a pressure block 14 is slidably installed in each water storage tank 13 through a conductive spring 12. A sealing ring is provided at the sliding joint of the inner wall of the sink 13, and the inner wall of the floor drain body 1 is provided with a plurality of water inlets 16 and a plurality of water nozzles 17, and each of the water inlets 16 and the water nozzles 17 are aligned with the position. The corresponding water storage tank 13 is connected, and each water inlet 16 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com