Gap type drainage ditch prefabrication and installation construction method based on core mold with air bag sleeved with PVC pipe

A PVC pipe, prefabrication and installation technology, applied in the direction of water supply devices, waterway systems, sewer pipe systems, etc., can solve the problems of high exhaust requirements, increased construction difficulty, and high construction difficulty, and achieve high construction quality and prefabrication efficiency High and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

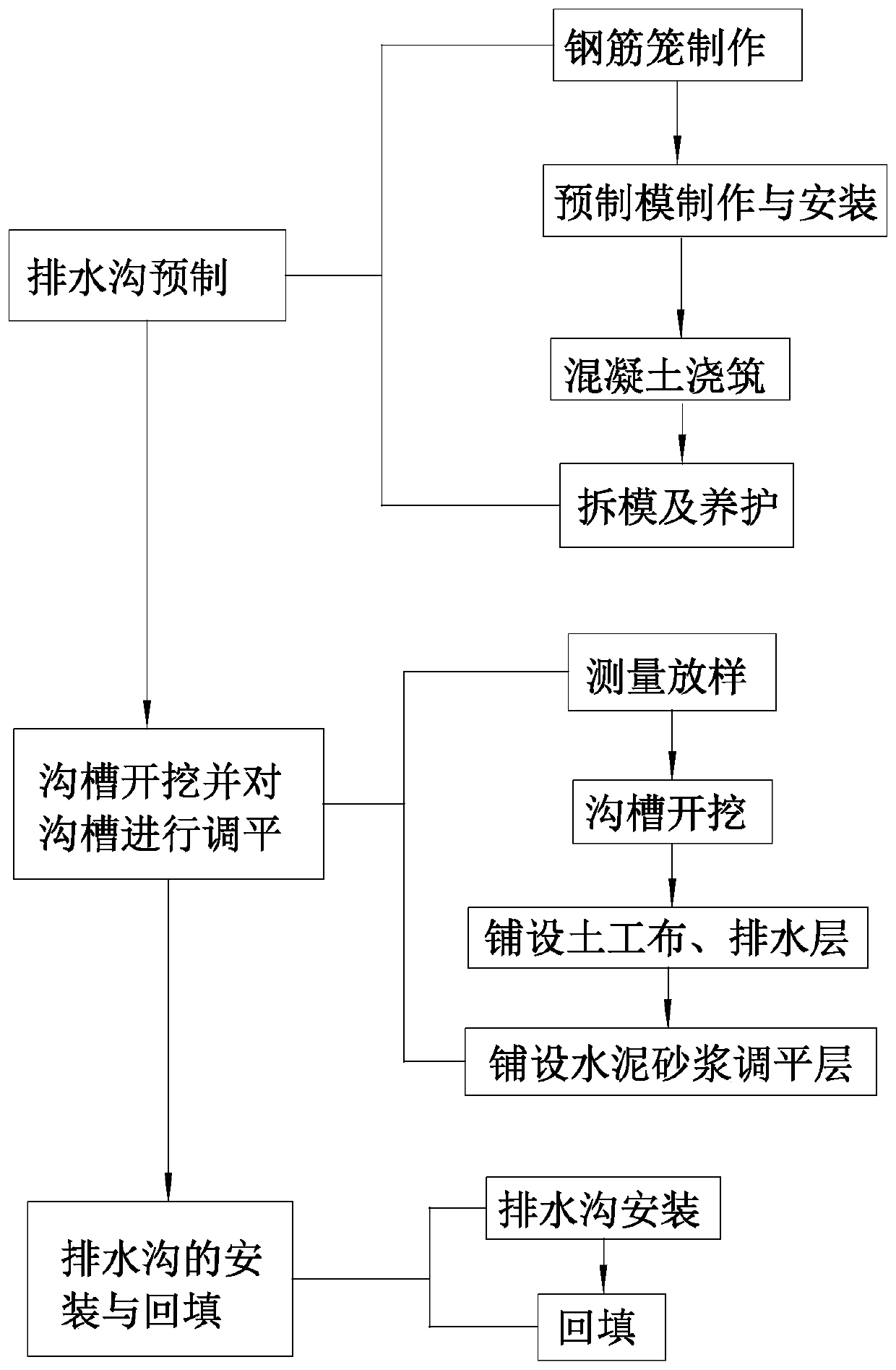

[0044] Embodiment 1, with reference to figure 1 , is a kind of prefabrication and installation construction method based on PVC pipe 2 inner sleeve airbag mandrel 10 slit type drainage ditch disclosed by the present invention, comprises the following steps:

[0045] Step S1 Drain prefabrication:

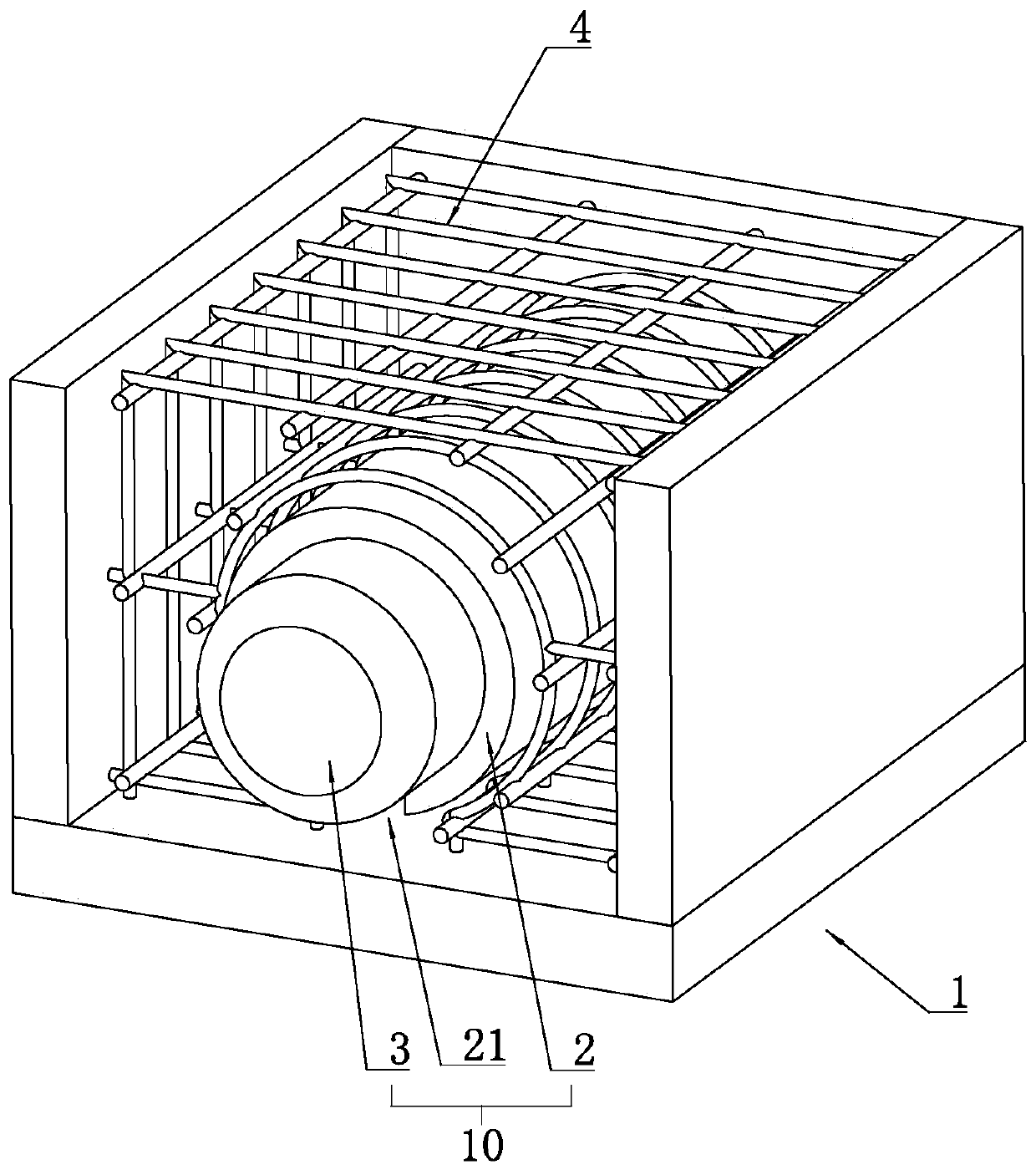

[0046] Step S1.1 making of reinforcement cage 4, refer to figure 2 When processing steel bars, the material should be cut according to the size required by the design. When the steel bars are bound and installed, they should be constructed according to the design drawings and construction specifications. Note that the specifications, sizes, and spacing of the steel bars must meet the requirements, and the thickness of the net protective layer of the main bars should be controlled according to the design requirements. The length and fullness of the steel bar weld should meet the requirements of the specification;

[0047] Step S1.2 Fabrication and installation of prefabricated mold...

Embodiment 2

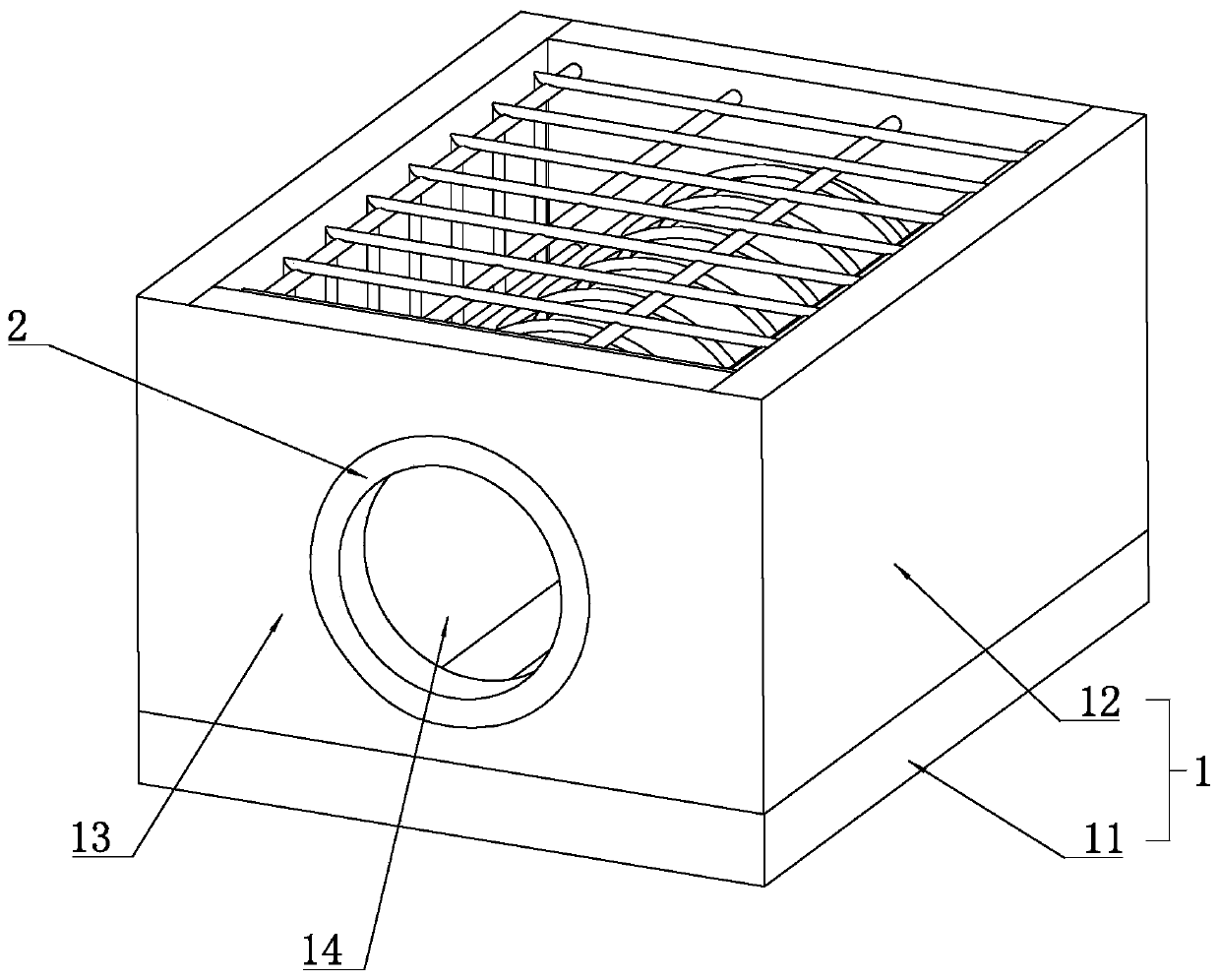

[0058] Embodiment 2, with reference to Figure 4 and Figure 5 , the difference from Example 1 is that the structure of the prefabricated mold 1 is different from the corresponding construction method,

[0059] The prefabricated mold 1 comprises a bottom mold 11, a side mold 12 and an end mold 13 which are mutually surrounded into a cube, and the bottom mold 11 and the side mold 12 are all hingedly connected to the bottom mold 11; The bottom surfaces are all in contact with the surface of the bottom mold 11, and the inner surface of the side mold 12 is in contact with the side end surface of the end mold 13; The two ends are embedded in the first inner template 15 of the step and pressed by the side mold 12, and the inner side of the bottom mold 11 is provided with a second inner template 16 that is pressed by the first inner template 15 and the end mold 13 respectively; The surfaces of the inner formwork 15 and the second inner formwork 16 are both provided with a plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com