Dyeing device for non-woven fabrics for medical masks

A non-woven fabric and mask technology, applied in the medical field, can solve problems such as single function, achieve the effect of convenient power output and improve dyeing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

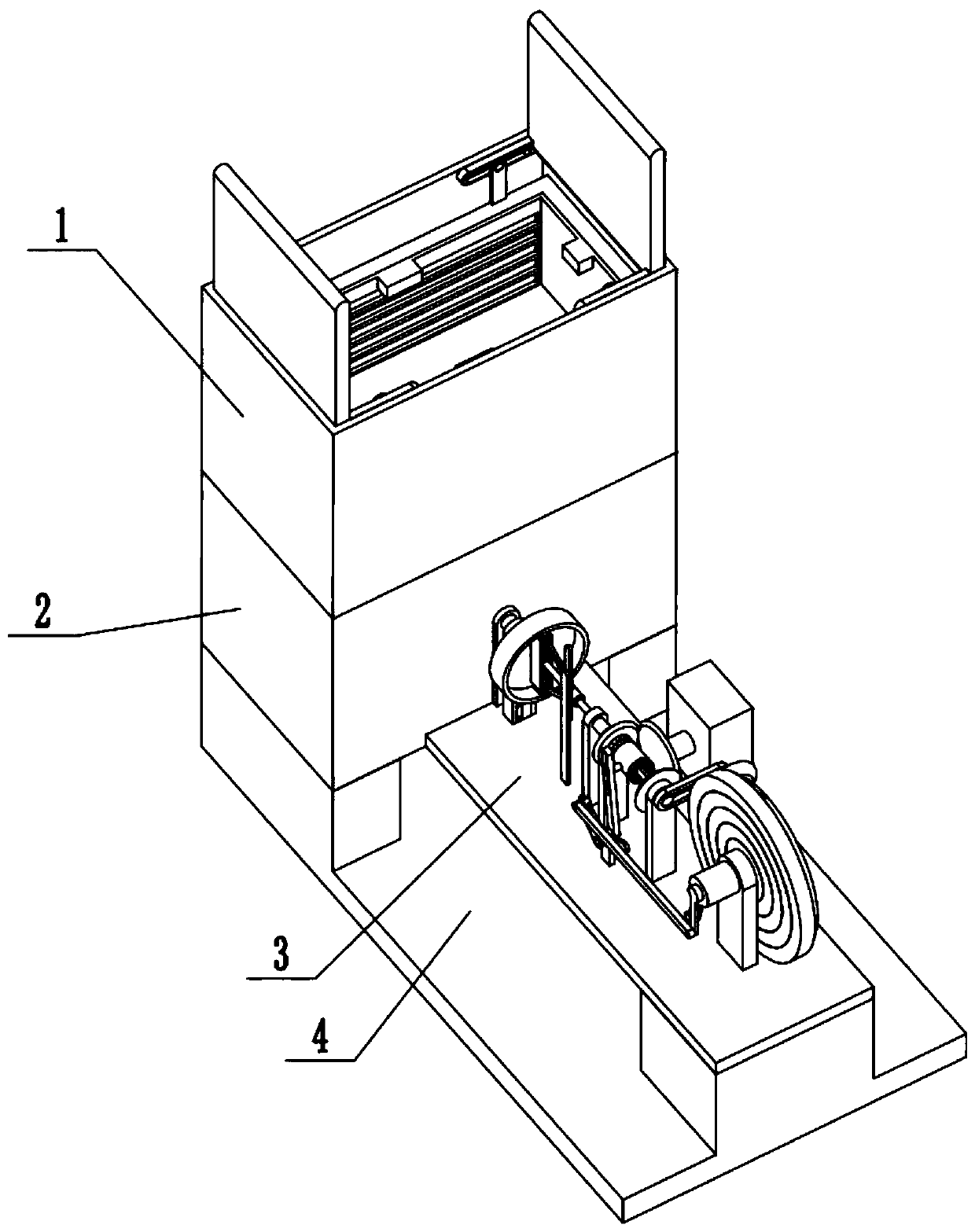

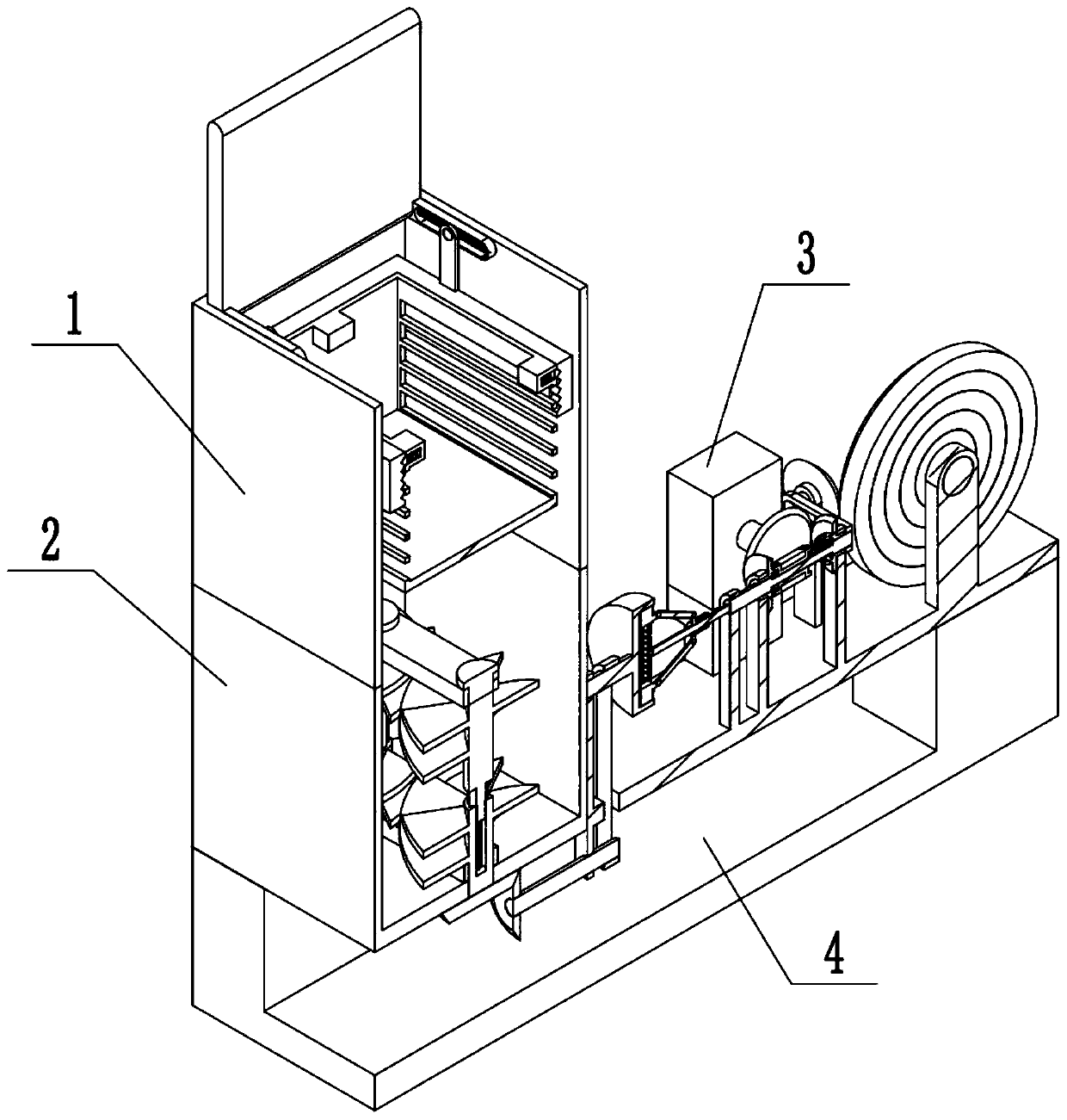

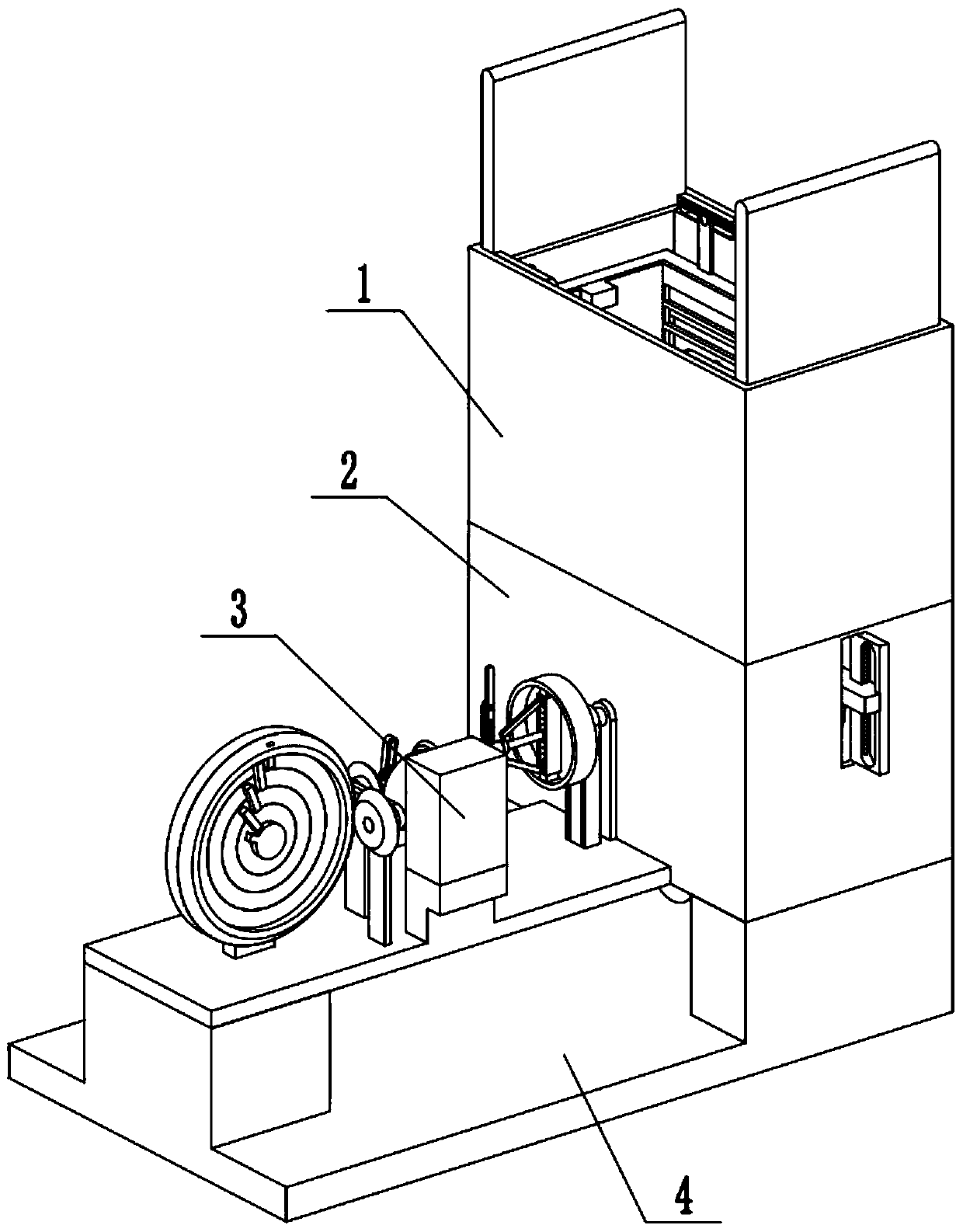

[0027] Combine below Figure 1-11 Description of this embodiment, a dip-dyeing device for non-woven medical masks, including a carrying assembly 1, a dip-dyeing assembly 2, a power source assembly 3, and a fixed chassis 4, characterized in that: the carrying assembly 1 and the dip-dyeing assembly The assembly 2 is connected, the power source assembly 3 is connected with the dipping assembly 2, and the fixed chassis 4 is connected with the dipping assembly 2 and the power source assembly 3.

specific Embodiment approach 2

[0029] Combine below Figure 1-11Describe this embodiment, this embodiment will further explain the first embodiment, the bearing assembly 1 includes a bearing outer frame 1-1, a closing rod 1-2, a driving sleeve 1-3, a bearing rectangular frame 1-4, a rectangular Through hole 1-5, card slot 1-6, clip 1-7, clip spring 1-8, upper sliding column 1-9, upper push spring 1-10, upper slider 1-11, card Slot 2 1-12, clip 2 1-13, clip spring 2 1-14, the closing rod 1-2 is rotationally connected with the bearing outer frame 1-1, and the driving sleeve 1-3 is slidingly connected with the bearing outer frame 1-1, The driving sleeve 1-3 is rotationally connected with the upper end slider 1-11, the first slot 1-6 and the second slot 1-12 are set on the driving sleeve 1-3, the first clip 1-7, the second clip 1- 13 is slidingly connected with the carrying rectangular frame 1-4, clip one 1-7, clip two 1-13 are connected with clip slot one 1-6, clip slot two 1-12, clip spring one 1-8 is arrang...

specific Embodiment approach 3

[0031] Combine below Figure 1-11 This embodiment will be described, and this embodiment will further explain Embodiment 1. The dipping assembly 2 includes a dipping outer frame 2-1, an inner end clamping groove 2-2, an inner end driving rod 2-3, and a connecting boss 2 -4. Connecting boss 2 2-5, lower belt 2-6, outer wall ear plate 2-7, spherical card slot 2-8, stirring blade 1 2-9, stirring blade 2 2-10, stirring blade 3 2- 11. Connecting boss 3 2-12, clip 3 2-13, clip spring 3 2-14, stirring blade 4 2-15, stirring blade 5 2-16, stirring blade 6 2-17, spherical clip 2-18, Spherical clamp spring 2-19, the inner end clamping groove 2-2 is arranged on the dipping outer frame 2-1, the outer wall ear plate 2-7 is fixedly connected with the dipping outer frame 2-1, and the spherical clamping groove 2-8 is arranged on the outer wall ear On the plate 2-7, clip three 2-13, spherical clip 2-18 are slidingly connected with the inner drive rod 2-3, and the clip spring three 2-14 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com