Circular glass cutting device

A cutting device, circular technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of low cutting efficiency, unable to ensure the maximum utilization of strip glass, etc., to reduce the generation of glass waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

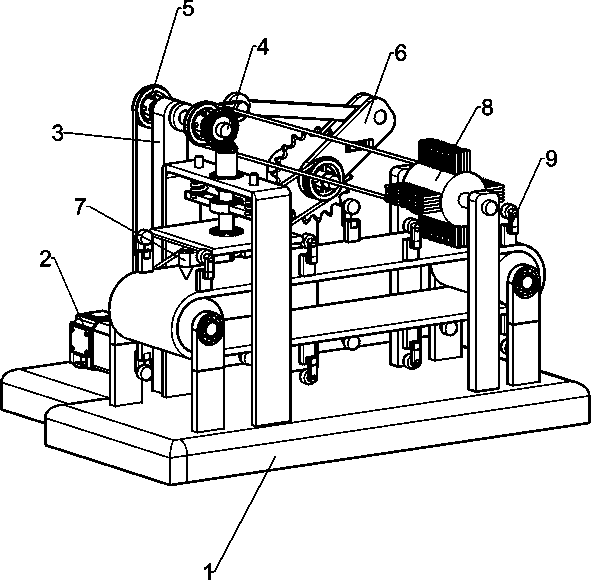

[0042] A circular glass cutting device such as figure 1 As shown, it includes a mounting base 1, a motor 2, a main shaft support frame 3, an output spindle 4, a first belt assembly 5, an intermittent motion mechanism 6 and a cutting mechanism 7, and the left front part of the mounting base 1 is equipped with a motor 2, and the mounting base 1. There is a main shaft support frame 3 on the left front. The main shaft support frame 3 is located on the right side of the motor 2. The upper part of the main shaft support frame 3 is rotatably connected to the output main shaft 4. There is a first shaft between the output shaft of the motor 2 and the left end of the output main shaft 4. The belt assembly 5 and the intermittent motion mechanism 6 are arranged on the left rear portion of the mounting base 1 and the output main shaft 4 , and a cutting mechanism 7 is arranged on the right front side of the mounting base 1 , and the cutting mechanism 7 is connected with the output main shaft...

Embodiment 2

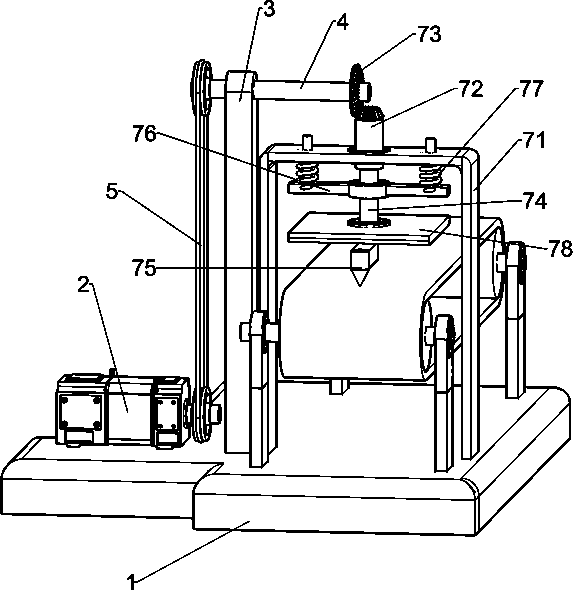

[0045] Overall, according to Figure 1-3 with Figure 5-6As shown in the diagram, the intermittent motion mechanism 6 includes a rotating rod 61, a connecting rod 62, a swing plate 63, a circular top block 64, a first spring 65, a support plate 66, an output rotating shaft 67, a ratchet 68, a first roller 69, The second belt assembly 610, the second drum 611 and the conveyor belt 612, the left side of the output main shaft 4 is equipped with a rotating rod 61, the rotating rod 61 is located on the right side of the main shaft support frame 3, the end of the rotating rod 61 is connected with a connecting rod 62 in a rotating manner, and the mounting seat 1. There is a support plate 66 at the rear of the left side. The upper part of the support plate 66 is connected to the output shaft 67 through a one-way bearing. A ratchet 68 is installed on the output shaft 67. A swing plate 63 is rotatably installed on the output shaft 67 on both sides of the ratchet 68. , the rear end of t...

Embodiment 3

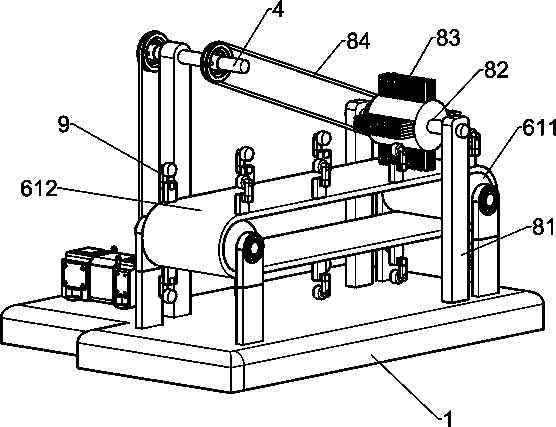

[0050] Specifically, such as figure 1 with Figure 4 As shown, a cleaning mechanism 8 is also included, and the cleaning mechanism 8 includes a support rod 81, a large rotating drum 82, a hair brush 83 and a third belt assembly 84, and the left and right sides of the rear right side of the mounting base 1 are provided with a support rod 81, A large rotating drum 82 is installed in rotation between the upper parts of the support rods 81 on both sides, and a plurality of brushes 83 are evenly arranged on the outside of the large rotating drum 82, and a third brush 83 is connected between the right side of the output main shaft 4 and the left side of the large rotating drum 82. Belt assembly 84.

[0051] After the motor 2 is started, the motor 2 drives the output spindle 4 to rotate, and the output spindle 4 drives the large rotating drum 82 to rotate through the third belt assembly 84, and the brush 83 on the outside of the large rotating drum 82 cleans the surface of the strip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com