Method for preparing rock wool by gasifying and melting industrial activated sludge for power generation

A technology of activated sludge, gasification and melting, applied in the direction of chemical instruments and methods, petroleum industry, gasification process, etc., can solve the problems of ecological environment threat, secondary pollution environment, insufficient disposal capacity, etc., and the processing scale can be large Small size, high resource utilization efficiency, and obvious effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

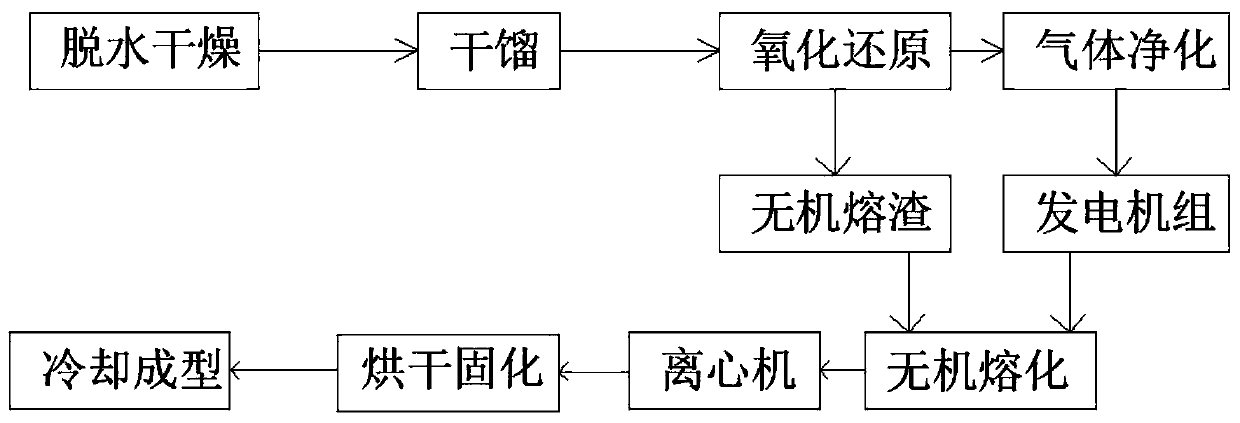

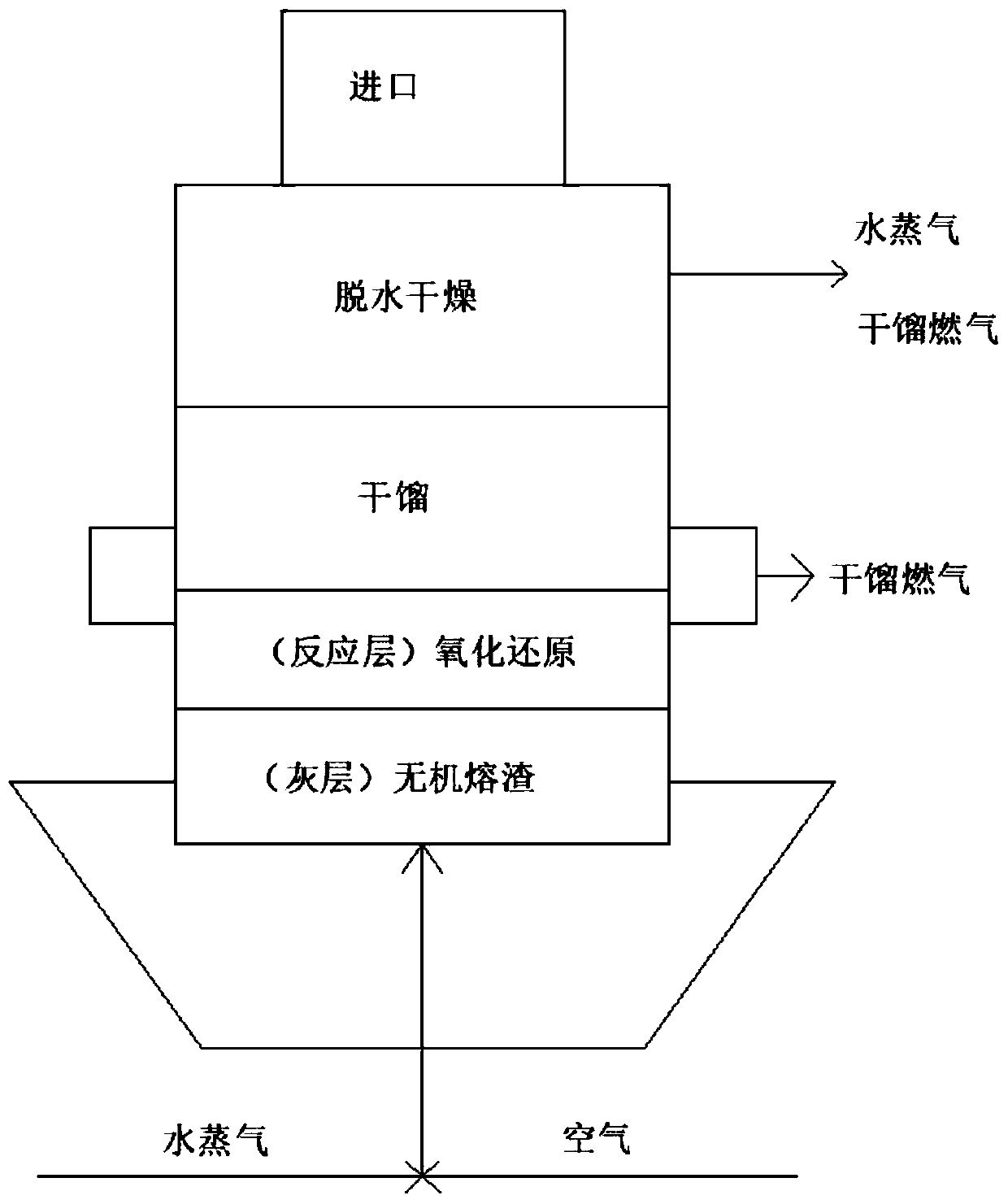

[0036] Such as Figure 1-Figure 2 Shown, the method for producing rock wool by gasification and melting of industrial activated sludge of the present invention,

[0037] A method for producing rock wool by gasifying and melting industrial activated sludge to generate electricity, comprising the following steps:

[0038] S1: Dehydration, put the industrial activated sludge into the pyrolysis gasification furnace from the top of the pyrolysis gasification furnace, contact with the pyrolysis gas at a temperature of 80-120 ℃ during the descending process, and dehydrate continuously within 1-2 hours Remove the attached water, the water becomes steam and the pyrolysis gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com