Slope pipeline welding method

A welding method and pipeline technology, which are applied in welding equipment, welding accessories, characteristics of welding rods, etc., can solve the problems of low welding efficiency of single torch, cumbersome processing of asymmetric grooves, and high processing cost of grooves. Conducive to management and alignment, ensuring the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

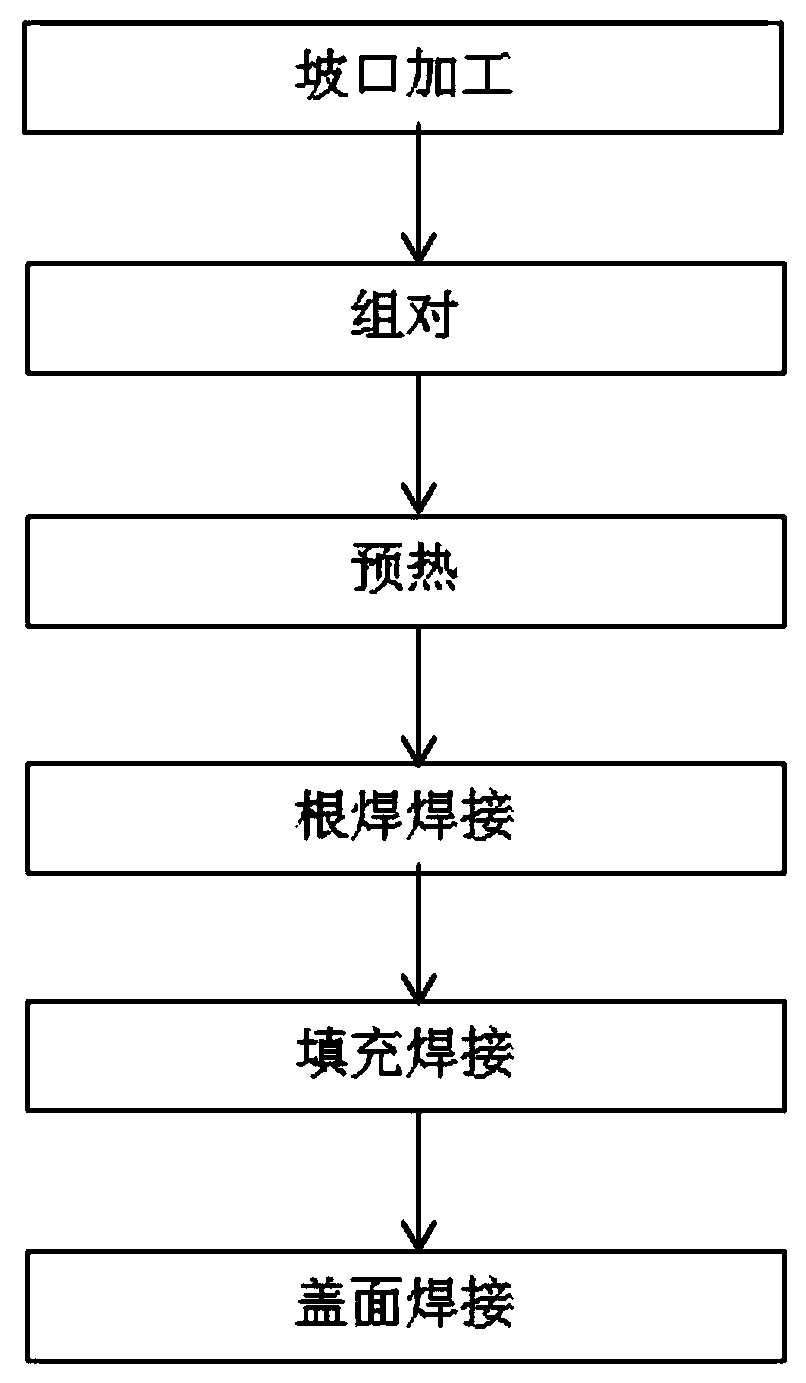

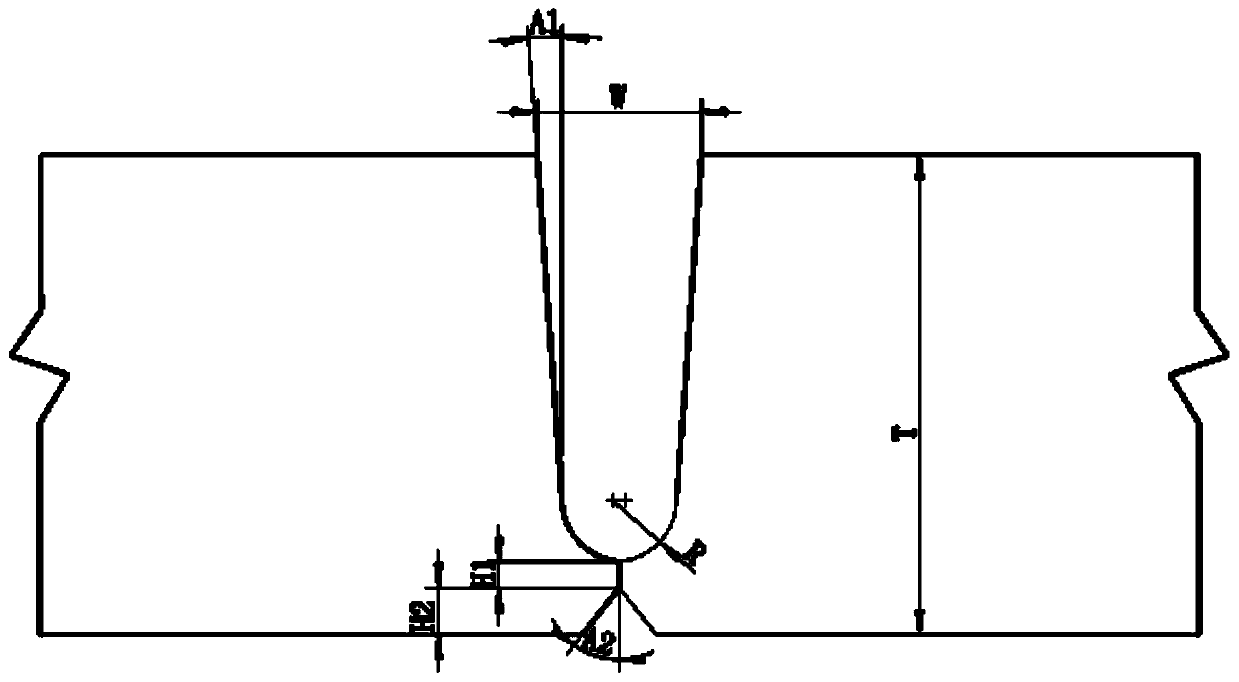

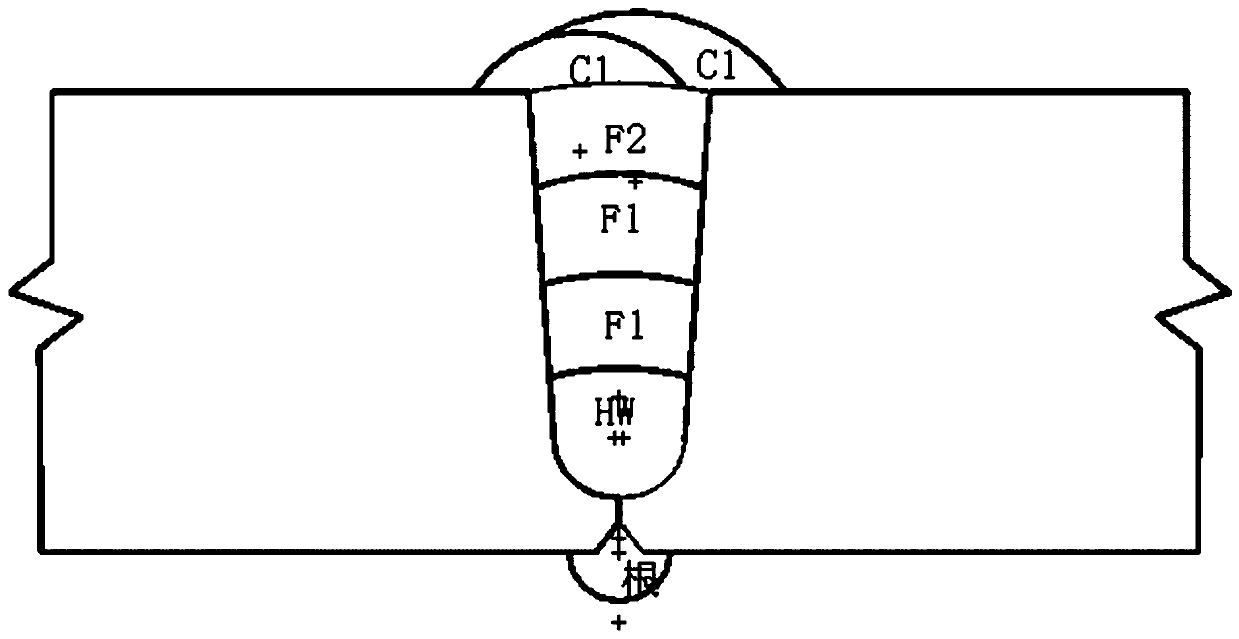

[0028] Embodiment: welding of pipelines in mountainous areas, the material is X70, and the specification is 1219×18.4. Beveling machine is used to process the pipe mouth to form a symmetrical UV composite bevel; the flexible intelligent pipe internal welding system is used to position and assemble the pipe mouth; use intermediate frequency heating or electric heating to assemble the pipe The mouth is preheated; the flexible intelligent pipeline internal welding system is used to complete the root welding of the weld, and the double torch pipeline welding system is used to complete the heat welding, filling and cover welding of the weld. The specific operation steps are:

[0029] Before the groove processing, clean the inner and outer surface of the steel pipe and the 150mm range on both sides. There should be no phosphorus, wear, rust, slag, grease, paint and other harmful substances that affect the welding quality. The nozzle and the 20mm range on both sides should be cleane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com