Intelligent milling cutter for metal product

A metal product, intelligent technology, applied in milling cutters, metal processing equipment, manufacturing tools, etc., can solve problems such as troublesome, cumbersome operation steps, difficult disassembly and assembly of tools, etc., to improve stability, prolong service life, disassembly and assembly Simple and convenient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

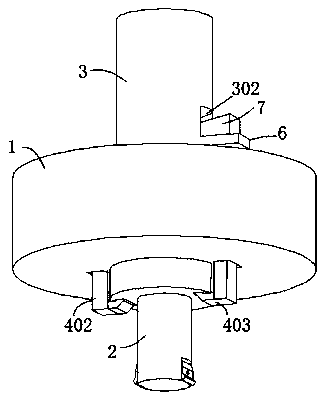

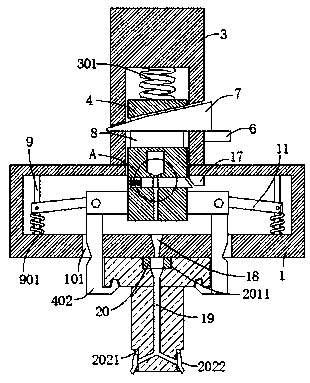

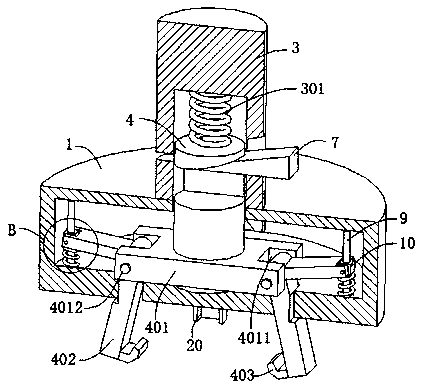

[0034] refer to figure 1 , figure 2 , image 3 , Figure 5 and Figure 6, an intelligent milling cutter for metal products, comprising a mount 1 and a cutter 2, the cutter 2 is connected to the bottom of the mount 1, the top of the mount 1 is connected to a connecting pipe 3, and the inner wall of the connecting pipe 3 is connected with a first elastic Element 301, the end of the first elastic element 301 away from the top inner wall of the connecting pipe 3 is connected with a moving rod 4, the moving rod 4 is movably connected in the mounting seat 1, the outer wall of the connecting pipe 3 is connected with a supporting plate 6, and the outer wall of the supporting plate 6 is slidingly connected with The first wedge block 7, the outer wall of the connecting pipe 3 is dug with the second concave hole 302 matched with the first wedge block 7, and the outer wall of the moving rod 4 is dug with a second groove 8 matched with the first wedge block 7. The outer wall of the ro...

Embodiment 2

[0037] refer to figure 2 , image 3 , Figure 4 and Figure 8 , an intelligent milling cutter for metal products, which is basically the same as Embodiment 1, furthermore, the inner wall of the mounting seat 1 is connected with a guide rod 9, the outer wall of the guide rod 9 is slidably connected with a slider 10, and the outer wall of the guide rod 9 is covered Connected with a second elastic element 901, the second elastic element 901 is placed between the bottom wall of the slider 10 and the inner wall of the mounting base 1, the outer wall of the swing rod 402 is fixedly connected with a connecting rod 11, and the connecting rod 11 is far away from one end of the swing rod 402 A fourth groove 111 is excavated, and the inner wall of the fourth groove 111 is connected with a second rotating shaft 1111, and the slider 10 is connected to the inner wall of the fourth groove 111 through the rotation of the second rotating shaft 1111; Or in the process of moving down, the sw...

Embodiment 3

[0040] refer to figure 2 , image 3 and Figure 7 , an intelligent milling cutter for metal products, which is basically the same as that of Embodiment 1, furthermore, an oil cavity 14 and a first oil delivery pipeline 15 are excavated in the moving rod 4, and the oil cavity 14 and the first oil delivery pipeline 15 are connected to each other Connected, the bottom wall of the mounting base 1 is dug with an oil leakage hole 18, the oil leakage hole 18 is placed directly below the first oil delivery pipeline 15, a second oil delivery pipeline 19 is dug in the cutter 2, and the two ends of the second oil delivery pipeline 19 The square hole 2011 and the third groove 2021 communicate with each other respectively, the inner wall of the moving rod 4 is dug with a fifth groove 16, the inner wall of the fifth groove 16 is connected with a third elastic element 161, and the third elastic element 161 is far away from the fifth groove One end of the inner wall of 16 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com