Welding method of stitch welding type multi-layered steel mesh skeleton

A welding method and mesh skeleton technology are applied in the field of composite pipe manufacturing to achieve the effects of strong pressure bearing capacity, light weight and guaranteed strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, not to limit the present invention.

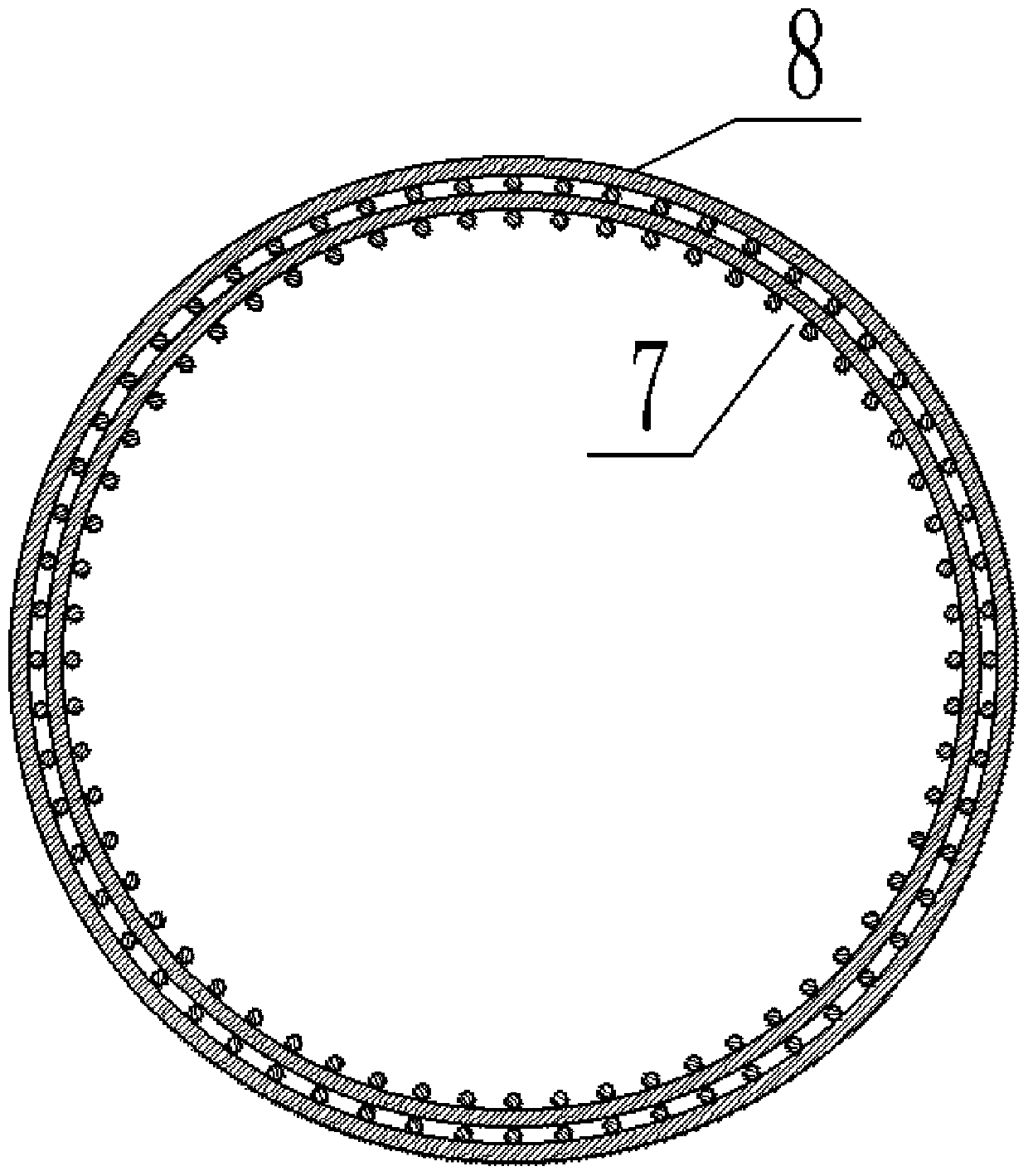

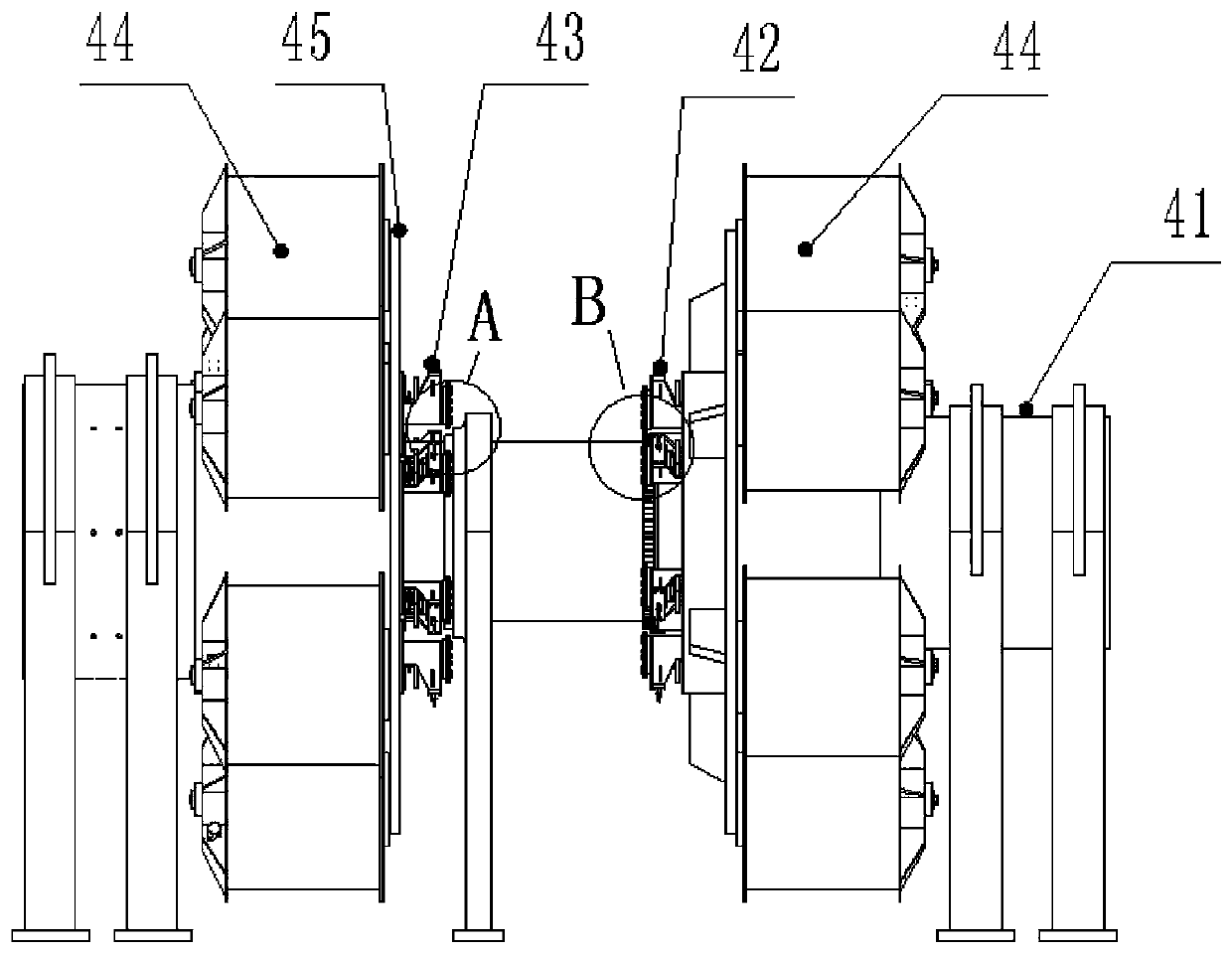

[0042] The invention discloses a stitch-welded multi-layer steel mesh skeleton, such as figure 1 , figure 2 As shown, it includes a tubular basic steel mesh skeleton 7 welded by a basic welding mechanism, and a plurality of secondary reinforced steel mesh skeletons are sequentially welded on the outside of the basic steel mesh skeleton 7 through multiple secondary welding mechanisms along its radial direction. 8, and each secondary reinforced steel mesh skeleton 8 is welded by the corresponding secondary welding mechanism, the warp and latitude on the adjacent secondary reinforced steel mesh skeleton 8 are welded and fixed, and the latitude and weft of the basic steel mesh skeleton 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com