Cleaning device for columnar microalgae cultivation facility

A cleaning device and microalgae technology, applied in the field of utensil cleaning, can solve problems such as obstacles to the discharge of cleaning water, large diameter and height of glass containers, broken glass containers, etc., and achieve the effect of improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

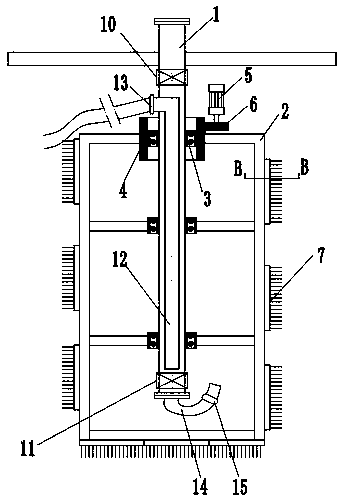

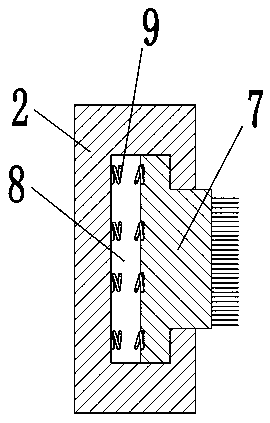

[0014] as attached figure 1 As shown, a cleaning device for a columnar microalgae cultivation facility includes a vertically arranged hard water supply pipe 1 and a cleaning frame 2. The water supply pipe 1 is made of a metal pipe, and the cleaning frame 2 is a rectangular frame. In this embodiment , The cleaning rack 2 adopts a single frame structure. According to actual needs, multiple rectangular frames can be used, and multiple rectangular frames can also be fixed in cross combination.

[0015] as attached figure 1 As shown, the water supply pipe 1 passes through the center of the upper and lower frames of the cleaning frame 2. When a multi-frame structure is adopted, the water supply pipe 1 is the center as the cross-connection point of the multi-frame.

[0016] The water supply pipe 1 and the cleaning frame 2 are connected by bearings 3. In or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com