Supersonic snowmaking nozzle and supersonic indoor snowmaker comprising same

A supersonic and snow-making technology, which is applied in the field of supersonic indoor snow-making machines and supersonic snow-making nozzles, can solve the problems of high energy consumption of the refrigeration system, long snow-making cycle, and increased snow-making rate, etc., to achieve snow-making The effect of shortened cycle, large amount of snow production, and high snow formation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

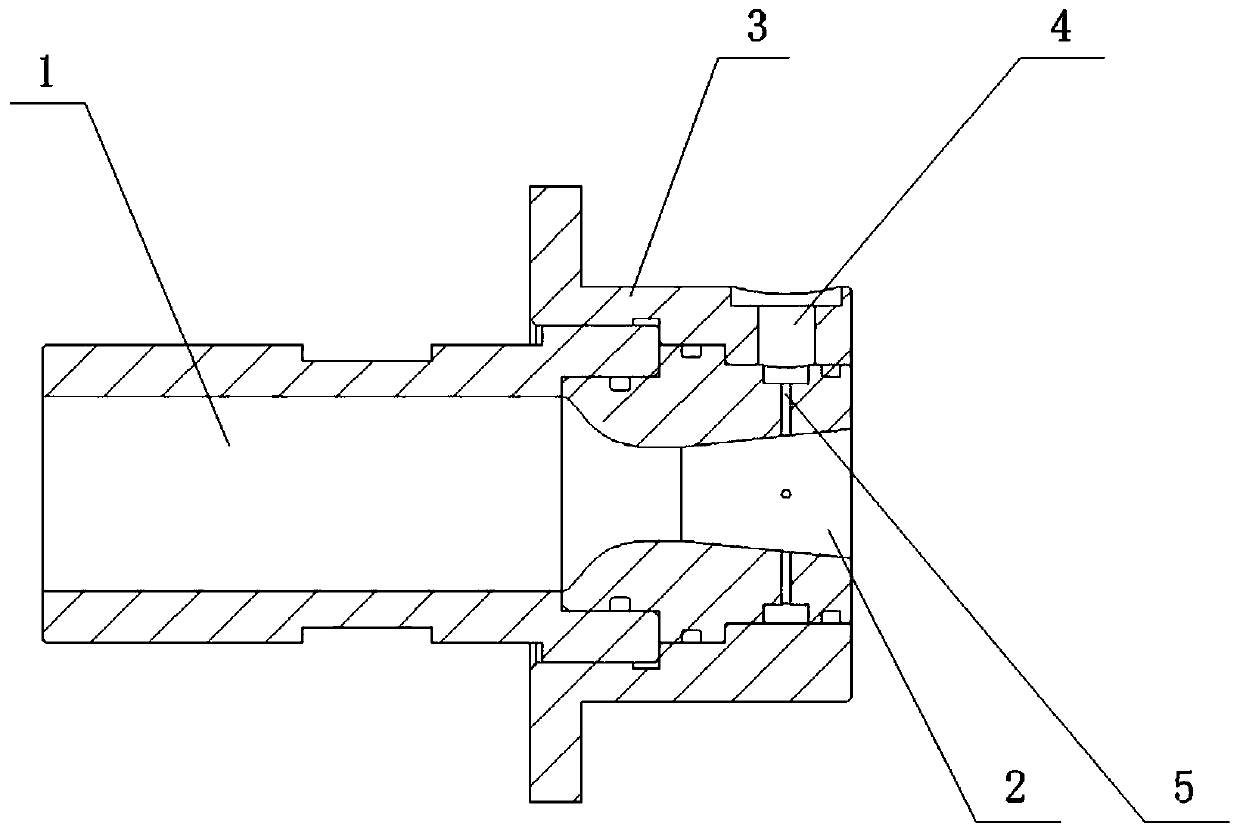

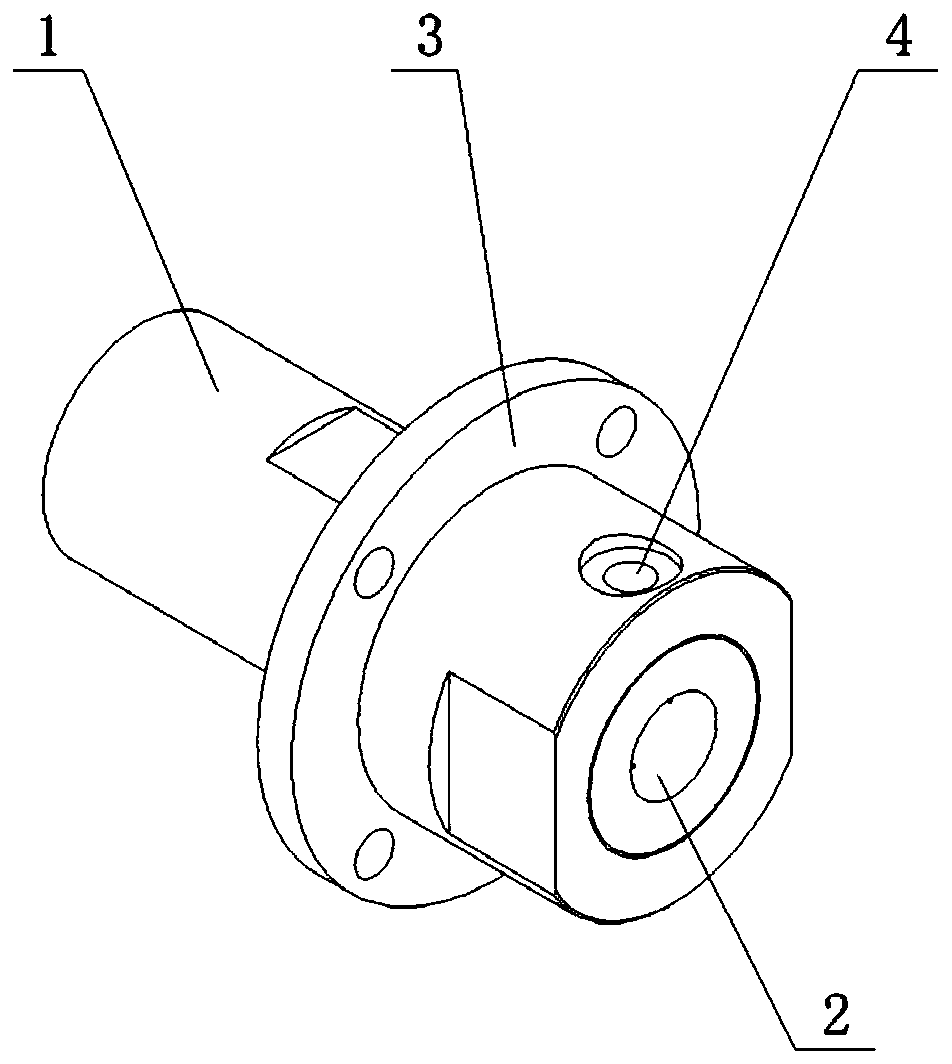

[0029] see figure 1 and figure 2 , the present invention provides a supersonic snowmaking nozzle, including an air flow channel and a water flow channel, the air flow channel is composed of a straight pipe section 1 and a Laval nozzle section 2, and the straight pipe section 1 and the Laval nozzle section 2 are connected And internally communicated, a lock nut 3 is set on the outside of the straight pipe section 1 and the Laval nozzle section 2, and the outer wall of the lock nut 3 is provided with a first water inlet hole 4, and the expansion of the Laval nozzle section 2 The outer wall of the section is provided with a second water inlet 5, and the first water inlet 4 and the second water inlet 5 are connected to form a water flow channel.

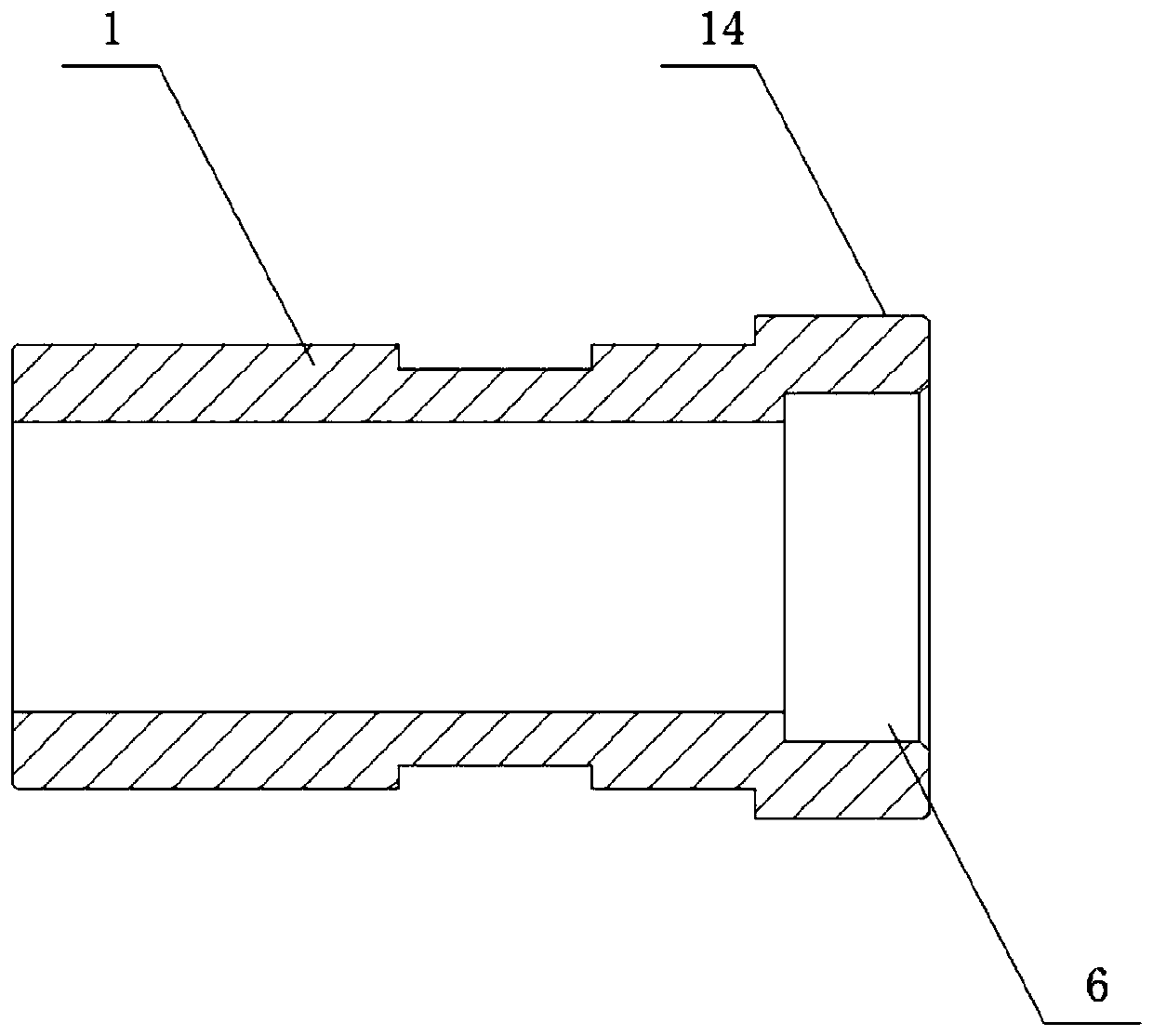

[0030] see image 3 , the end of the straight pipe section 1 docked with the Laval nozzle section 2 is provided with a counterbore 6, the size of the counterbore 6 matches the Laval nozzle section 2, so that the Laval nozzle section 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com