Sawing machine and method for controlling a sawing machine

A technology of sawing machines and saw blades, which is applied in the field of bow sawing machines to achieve the effect of prolonging life and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

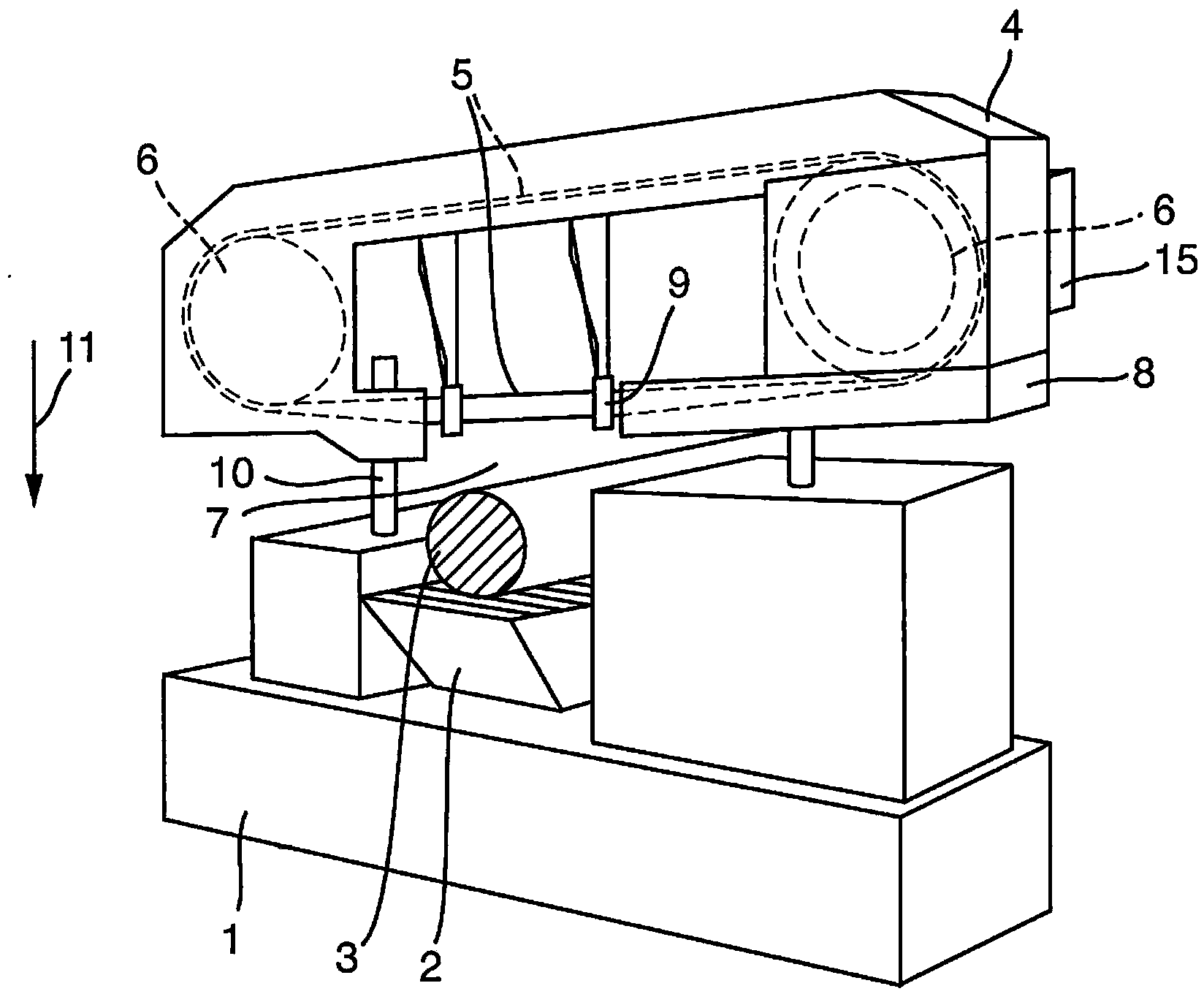

[0039] figure 1 Schematically shows a band sawing machine with: a base 1; a saw table 2 mounted on the base 1 for a workpiece 3 to be sawed; and a saw module 4 movable relative to the base 1, in which the The saw band 5 runs around the two rollers 6 without interruption. In the cutting area 7 , the saw band 5 runs outside the saw module housing 8 , where the saw band is guided by two saw band guides 9 arranged on the right and left of the cutting area 7 . These saw band guides 9 each comprise two lateral saw band guides and a saw band back guide, wherein the saw band back guide is damped by means of a spring set, so that the saw band 5 can be elastic against the force of the spring set retreat upwards.

[0040] The saw module 4 is located on the guide part 10 and can move up and down relative to the base 1 . The lowering movement is the sawing feed movement 11 .

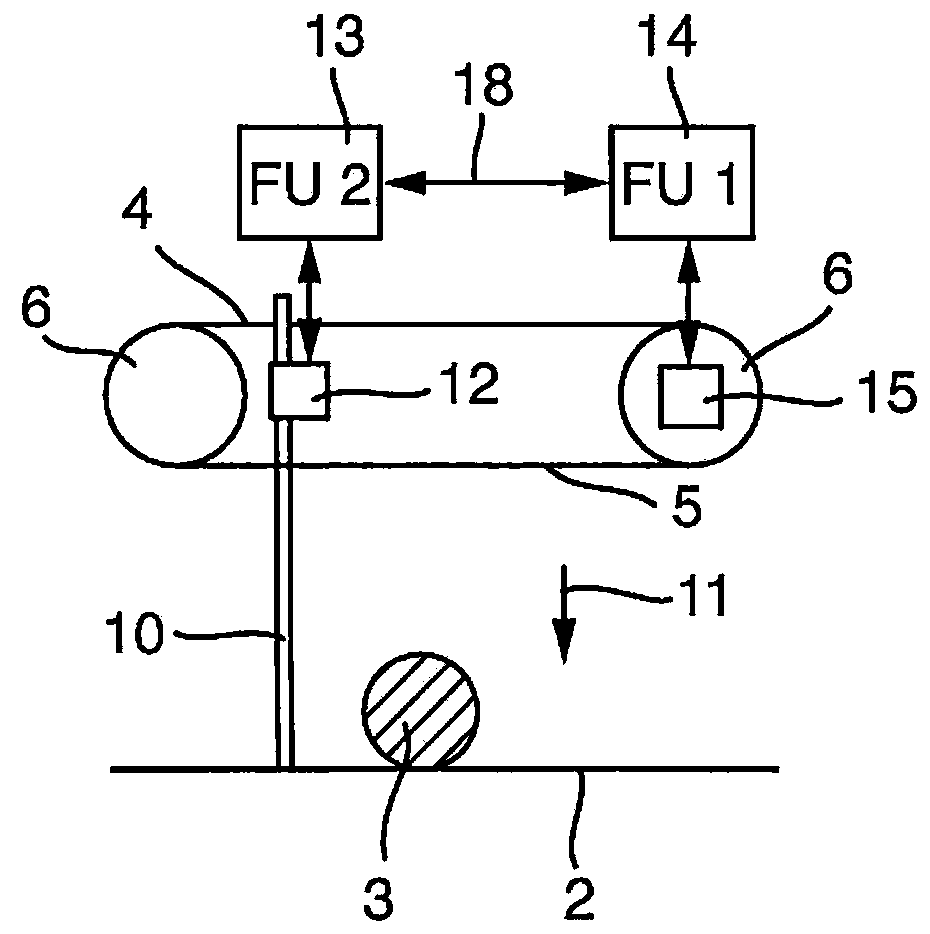

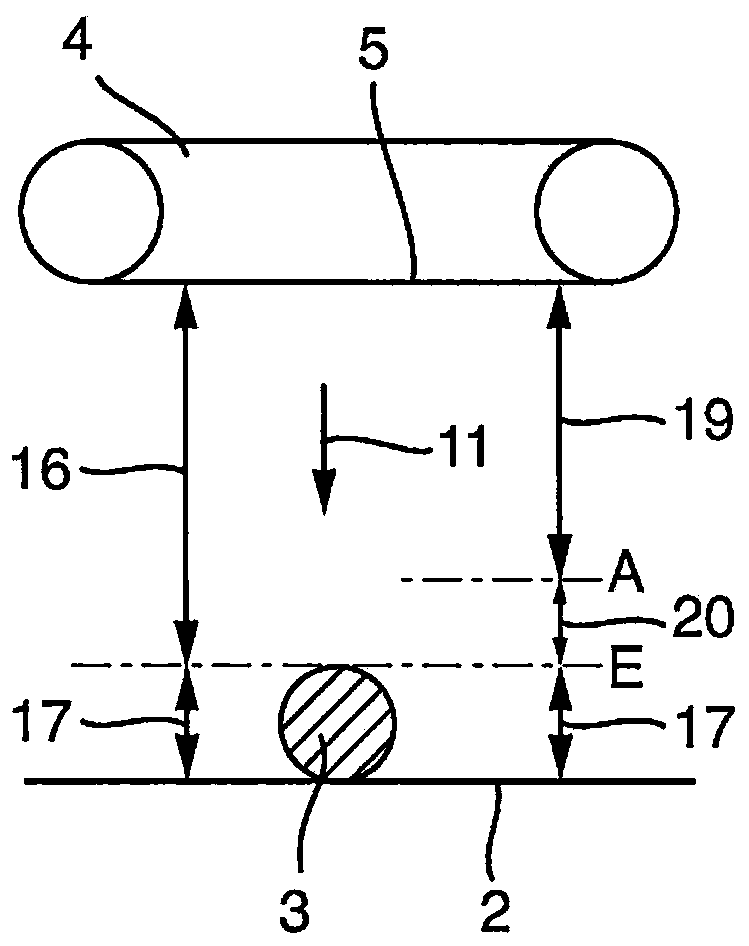

[0041] combine figure 2 (as figure 1 A schematic diagram of the basic components of the invention of the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com