Preparation method of porous aerogel composite material and porous aerogel composite material

A porous airgel and composite material technology, applied in the field of composite material preparation, can solve problems such as the need to increase the saturated adsorption capacity, difficult penetration of heavy metal ions, lack of structural stability, etc., to achieve improved adsorption effect, improved adsorption effect, excellent mechanical properties performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

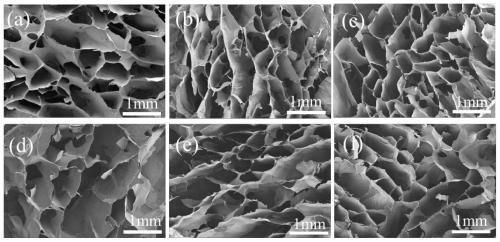

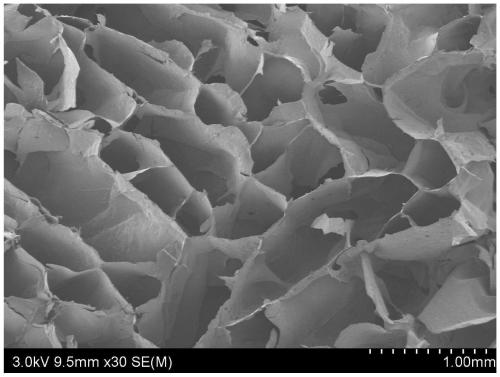

Image

Examples

Embodiment 1

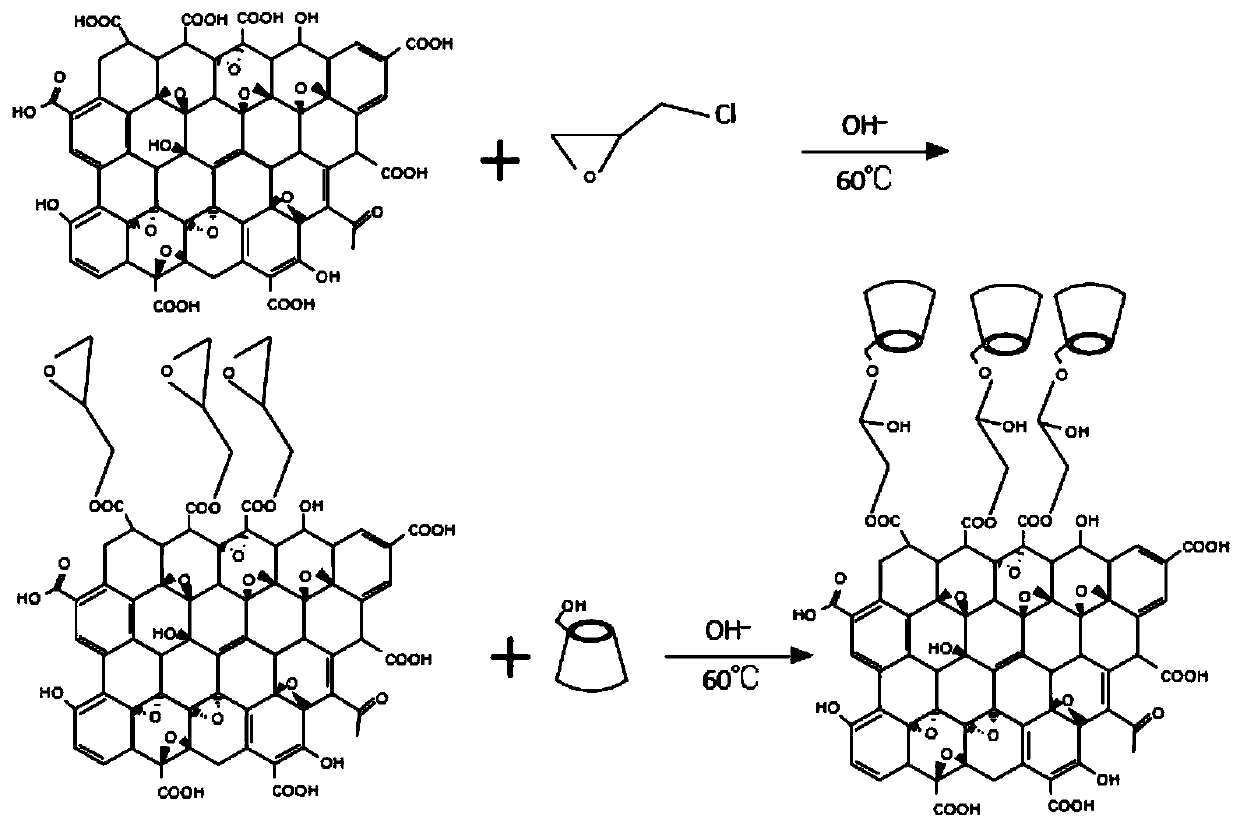

[0040] S1. React graphene oxide with a modification aid to obtain pre-modified graphene oxide. Step S1 is specifically:

[0041] Prepare 200ml of graphene oxide aqueous solution with a concentration of 5g / L, and adjust the pH value of the solution to 9.5 with 1% NaOH, and add 20g of epichlorohydrin drop by drop under magnetic stirring in a water bath at 60°C. Stirring was continued for 3 hours, and then the product was centrifuged and washed with deionized water to obtain pre-modified graphene oxide.

[0042] S2. Grafting cyclodextrin onto pre-modified graphene oxide to obtain cyclodextrin-modified graphene oxide. Step S2 is specifically:

[0043] Disperse the pre-modified graphene oxide obtained in step S1 in 200mL of carbonate buffer, then add 15g of β-cyclodextrin, stir magnetically for 3 hours in a water bath at 60°C, and then centrifuge the product with deionized water Washing 3 times to obtain β-cyclodextrin modified graphene oxide. In other embodiments, the cyclodextr...

Embodiment 2

[0050] S1. React graphene oxide with a modification aid to obtain pre-modified graphene oxide. Step S1 is specifically:

[0051] Prepare 200ml of graphene oxide aqueous solution with a concentration of 5g / L, and adjust the pH value of the solution to 9.5 with 1% NaOH, and add 20g of epichlorohydrin drop by drop under magnetic stirring in a water bath at 60°C. Stirring was continued for 3 hours, and then the product was centrifuged and washed with deionized water to obtain pre-modified graphene oxide.

[0052] S2. Grafting cyclodextrin onto pre-modified graphene oxide to obtain cyclodextrin-modified graphene oxide. Step S2 is specifically:

[0053] Disperse the pre-modified graphene oxide obtained in step S1 in 200mL of carbonate buffer, then add 15g of β-cyclodextrin, stir it magnetically for 3 hours in a water bath at 60°C, and then centrifuge the product with deionized water Washing 3 times to obtain β-cyclodextrin modified graphene oxide.

[0054] S3, mixing the anion-m...

Embodiment 3

[0059] S1. React graphene oxide with a modification aid to obtain pre-modified graphene oxide. Step S1 is specifically:

[0060] Prepare 200ml of graphene oxide aqueous solution with a concentration of 5g / L, and adjust the pH value of the solution to 9.5 with 1% NaOH, and add 20g of epichlorohydrin drop by drop under magnetic stirring in a water bath at 60°C. Stirring was continued for 3 hours, and then the product was centrifuged and washed with deionized water to obtain pre-modified graphene oxide.

[0061] S2. Grafting cyclodextrin onto pre-modified graphene oxide to obtain cyclodextrin-modified graphene oxide. Step S2 is specifically:

[0062] Disperse the pre-modified graphene oxide obtained in step S1 in 200mL of carbonate buffer, then add 15g of β-cyclodextrin, stir it magnetically for 3 hours in a water bath at 60°C, and then centrifuge the product with deionized water Washing 3 times to obtain β-cyclodextrin modified graphene oxide.

[0063] S3, mixing the anion-m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap