Preparation method of anti-fouling oil-water separation composite membrane

A composite membrane, sewage oil-water technology, applied in the separation method, liquid separation, semi-permeable membrane separation, etc., can solve the problems of chemical reagent secondary pollution, low efficiency of oil-water separation, complicated preparation process, etc., to speed up the precipitation, Effect of effective membrane flux, improved mechanical properties and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

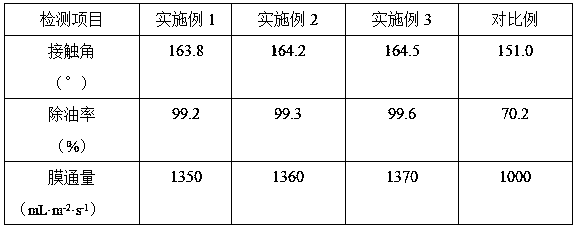

Examples

Embodiment 1

[0040] In terms of parts by weight, weigh 10 parts of nano-titanium dioxide powder, 20 parts of polyvinyl alcohol, 8 parts of methanol, and 80 parts of deionized water, add polyvinyl alcohol into the deionized water, and stir at 200 r / min for 12 minutes at normal temperature. To obtain a polyvinyl alcohol solution, add nano-titanium dioxide powder into the polyvinyl alcohol solution, stir at a speed of 400 r / min in a water bath at 40° C. for 1 hour to obtain a nano-titanium dioxide suspension, and place the nano-titanium dioxide suspension in an ultrasonic disperser, Ultrasonic treatment at 300W for 40min at 30°C to obtain a nano-titanium dioxide dispersion. Slowly add methanol dropwise to the nano-titanium dioxide dispersion at a rate of 20mL / min, stir at room temperature for 20min at a speed of 160r / min, and place Centrifuge in a centrifuge at a speed of 3500r / min for 15min, remove the solid in the lower layer, wash 3 times with absolute ethanol, and dry in the shade at room ...

Embodiment 2

[0042] In parts by weight, weigh 15 parts of nano-titanium dioxide powder, 30 parts of polyvinyl alcohol, 12 parts of methanol, and 120 parts of deionized water, add polyvinyl alcohol into the deionized water, and stir at 220 r / min for 14 minutes at normal temperature. To obtain a polyvinyl alcohol solution, add nano-titanium dioxide powder into the polyvinyl alcohol solution, stir at a speed of 500 r / min for 1.5 h in a water bath at 45°C to obtain a nano-titanium dioxide suspension, and place the nano-titanium dioxide suspension in an ultrasonic disperser , under the condition of 35°C with a power of 350W for 50min to obtain a nano-titanium dioxide dispersion, methanol was slowly added dropwise to the nano-titanium dioxide dispersion at a rate of 30mL / min, stirred at a speed of 170r / min at room temperature for 25min, and then Place in a centrifuge and centrifuge at 3500r / min for 17min, remove the solid in the lower layer, wash 4 times with absolute ethanol, and dry in the shad...

Embodiment 3

[0044]In parts by weight, weigh 20 parts of nano-titanium dioxide powder, 40 parts of polyvinyl alcohol, 16 parts of methanol, and 160 parts of deionized water, add polyvinyl alcohol into the deionized water, and stir at a speed of 240 r / min for 16 minutes at room temperature. To obtain a polyvinyl alcohol solution, add nano-titanium dioxide powder into the polyvinyl alcohol solution, and stir at a speed of 600 r / min for 2 hours in a water bath at 50° C. to obtain a nano-titanium dioxide suspension, and place the nano-titanium dioxide suspension in an ultrasonic disperser, Ultrasonic treatment at 40°C with a power of 400W for 60min to obtain a nano-titanium dioxide dispersion, slowly add methanol dropwise to the nano-titanium dioxide dispersion at a rate of 40mL / min, stir at a speed of 180r / min for 30min at room temperature, and then place Centrifuge in a centrifuge at a speed of 3500r / min for 20min, remove the solid in the lower layer, wash 5 times with absolute ethanol, and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com