A Multi-loop Biased Magnetostrictive Actuator Excited by Parallel Twisted Wire Harness

A magnetostrictive and magnetostrictive rod technology, which is applied to piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc. and other problems, to achieve the effect of reducing the working heat, prolonging the continuous working time, and uniform bias field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

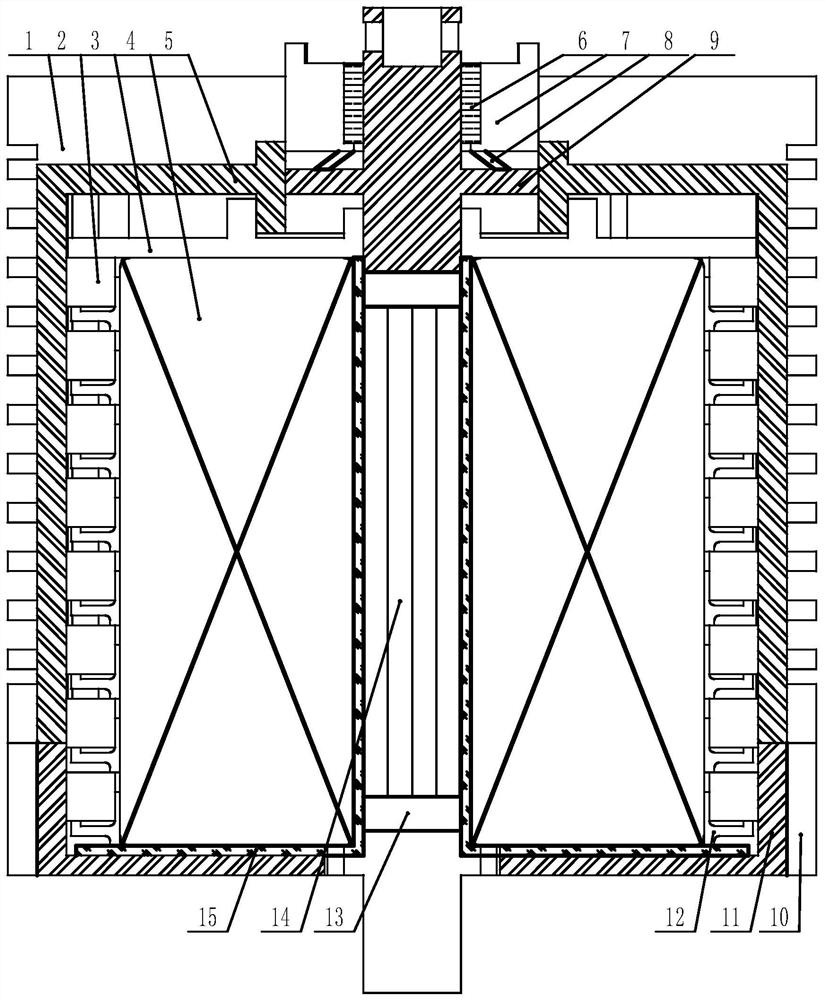

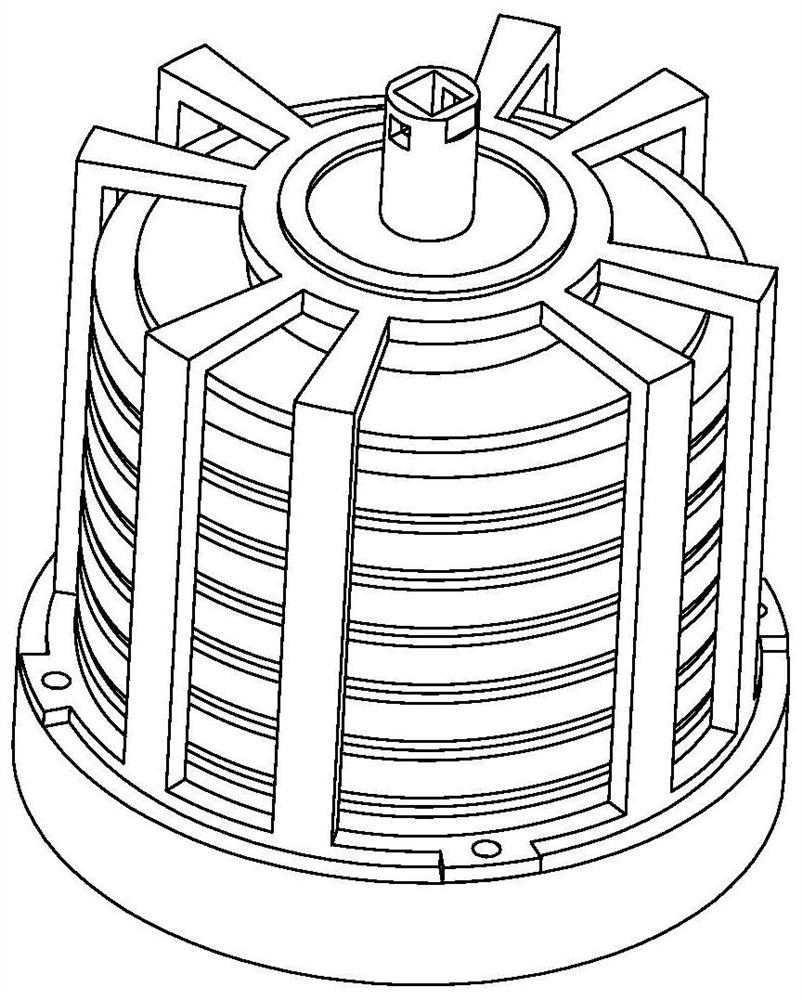

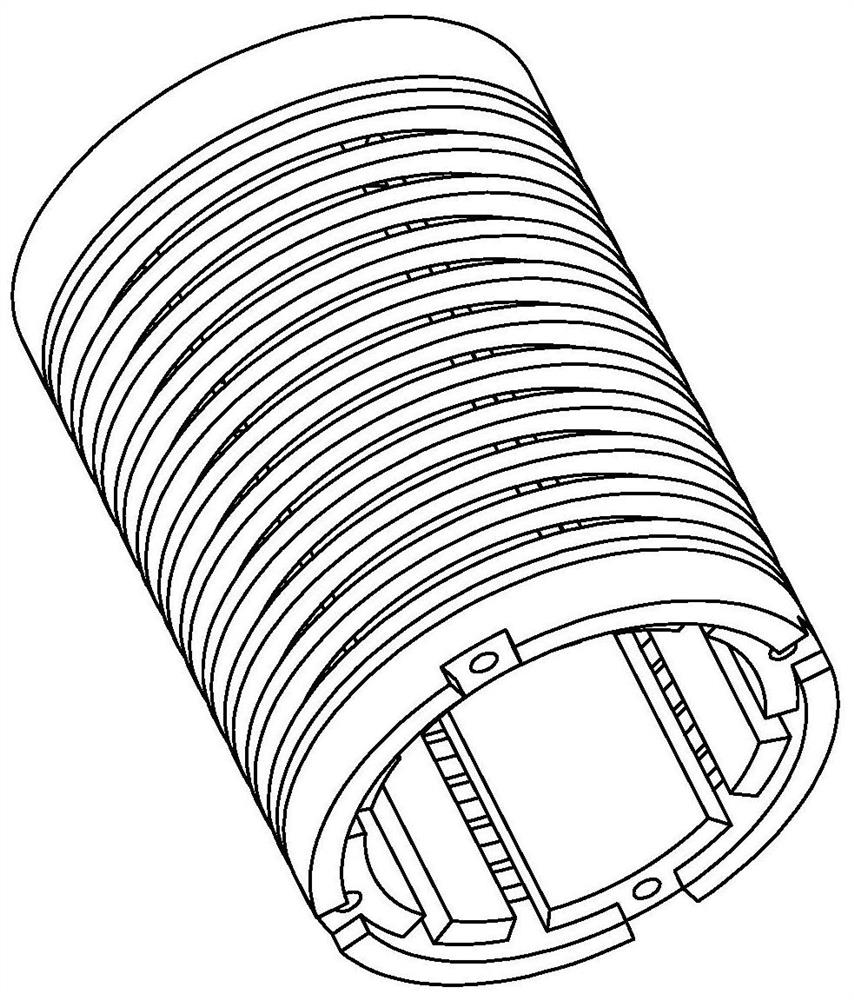

[0033] like Figure 1-9 Among them, the multi-ring bias magnetostrictive actuator excited by the parallel twisted wire harness of the present invention mainly includes the following parts: displacement generation and output assembly, magnetic conduction circuit, bias magnetic field generation assembly, excitation magnetic field generation assembly.

[0034] like figure 1 As shown, the displacement generating and output assembly includes: an adjusting end cover 7 , a linear bearing 6 , a disc spring 8 , an output rod 9 , a heat conductor 3 and a sliced magnetostrictive rod 14 . The lower part of the adjusting end cap 7 fixed on the shell is pressed against the disc spring 8, and when the adjusting end cap 7 is screwed forward and backward, the preload of the disc spring 8 is also changing. In general, the preload has a more appropriate range. The linear bearing 6 is installed in the adjustment end cover 7 with a transition fit. The linear bearing 6 is a self-lubricating lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com