7-ADCA mother liquor recovery treatment method

A 7-ADCA, mother liquor recovery technology, applied in filtration treatment, water/sewage treatment, natural water treatment, etc., can solve problems such as difficulty in meeting environmental protection requirements, inability to simultaneously recover high-quality ammonium sulfate and 7-ADCA, etc. Easy to operate, obvious effect, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

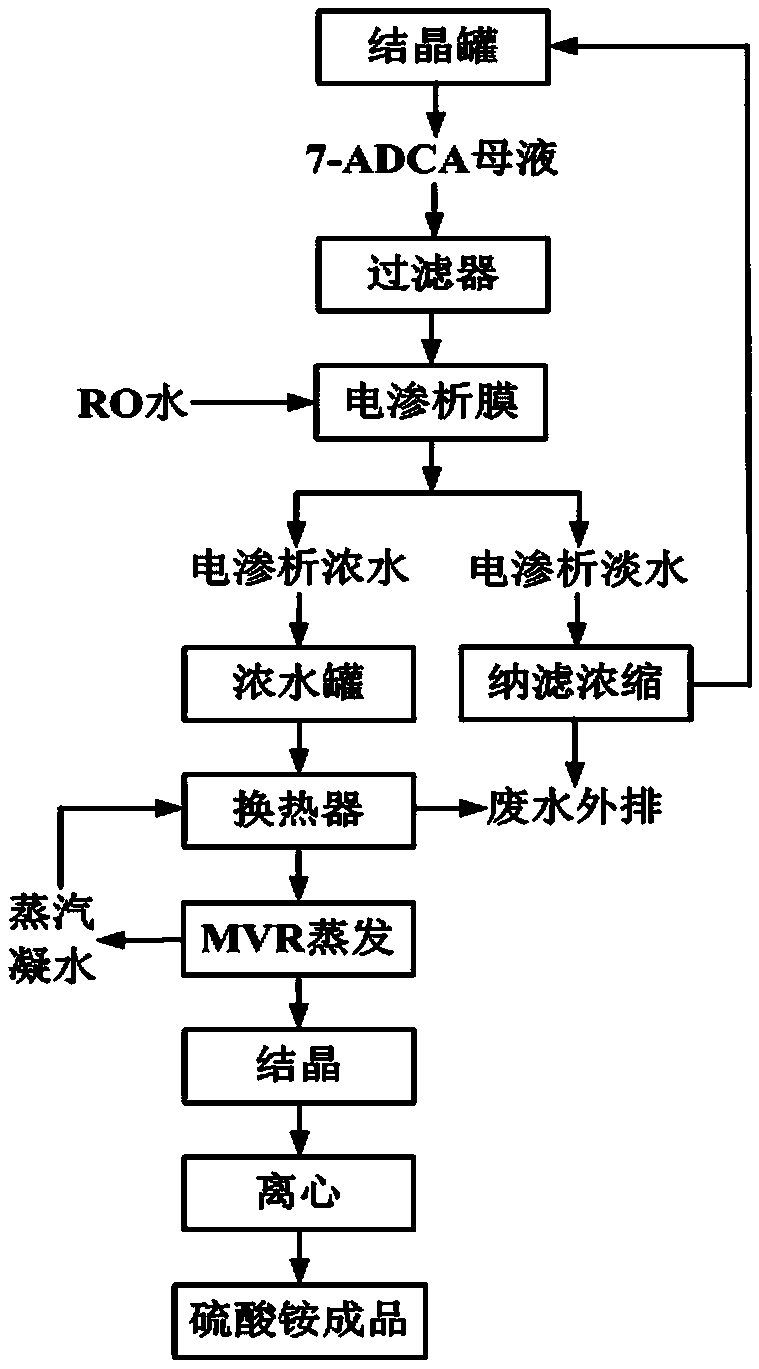

[0023] Such as figure 1 Shown is a schematic flow sheet of a 7-ADCA mother liquor recovery treatment method provided by the invention, comprising the following steps:

[0024] The raw materials are separated by crystallization and centrifugation to obtain 7-ADCA finished product and 7-ADCA mother liquor. The main substances contained in the mother liquor are inorganic salts and other organic impurities, and part of 7-ADCA (concentration 0.8 mg / mL), of which the COD concentration is 3800mg / L, SO 4 2- The concentration is 55000mg / L, NH 4+ The concentration is 15000mg / L, (NH 4 ) 2 SO 4 Concentration is 7%, pH is 4.0, wastewater volume is 140m 3 .

[0025] After the 7-ADCA mother liquor is collected by a temporary storage tank, it is first filtered through a filter, and then the 4m 3 / h flow rate into the electrodialysis unit for treatment. Utilizing the selective permeability of the ion exchange membrane of the electrodialysis device, the ammonium ions and sulfate ions w...

Embodiment 2

[0029] The raw materials are separated by crystallization and centrifugation to obtain 7-ADCA finished product and 7-ADCA mother liquor. The main substances contained in the mother liquor are inorganic salts and other organic impurities, and some 7-ADCA (concentration 1.0 mg / mL), of which the COD concentration is 4000mg / L, SO 4 2- The concentration is 58000mg / L, NH 4+ The concentration is 16000mg / L, (NH 4 ) 2 SO 4 The concentration is 7.3%, the pH is 4.0, and the wastewater volume is 120m 3 .

[0030] After the 7-ADCA mother liquor is collected by a temporary storage tank, it is first filtered through a filter, and then the 4m 3 / h flow rate into the electrodialysis unit for treatment. Utilizing the selective permeability of the ion-exchange membrane of the electrodialysis device, the ammonium ion and sulfate ion with strong ionization degree in the mother liquor pass through the membrane to obtain ammonium sulfate concentrate (electrodialysis concentrated water 7.6), a...

Embodiment 3

[0034] The raw materials are separated by crystallization and centrifugation to obtain 7-ADCA finished product and 7-ADCA mother liquor. The main substances contained in the mother liquor are inorganic salts and other organic impurities, and some 7-ADCA (concentration 1.2 mg / mL), of which the COD concentration is 4200mg / L, SO 4 2- The concentration is 60000mg / L, NH 4+ The concentration is 17000mg / L, (NH 4 ) 2 SO 4 Concentration is 7.5%, pH is 4.0, wastewater volume is 100m 3 .

[0035] After the 7-ADCA mother liquor is collected by a temporary storage tank, it is first filtered through a filter, and then the 4m 3 / h flow rate into the electrodialysis unit for treatment. Utilizing the selective permeability of the ion exchange membrane of the electrodialysis device, the ammonium ions and sulfate ions with strong ionization degree in the mother liquor pass through the membrane to obtain ammonium sulfate concentrate (electrodialysis concentrated water), and the ammonium sulf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com