Preparation method of novel rare earth red pigment gamma-Ce2S3

A red pigment, -ce2s3 technology, is applied in the field of preparation of new rare earth red pigment γ-Ce2S3, can solve the problems of tinting strength, gloss, purity and color strength to be improved, achieves simple and reliable preparation method, stable experimental results, The effect of enhanced adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

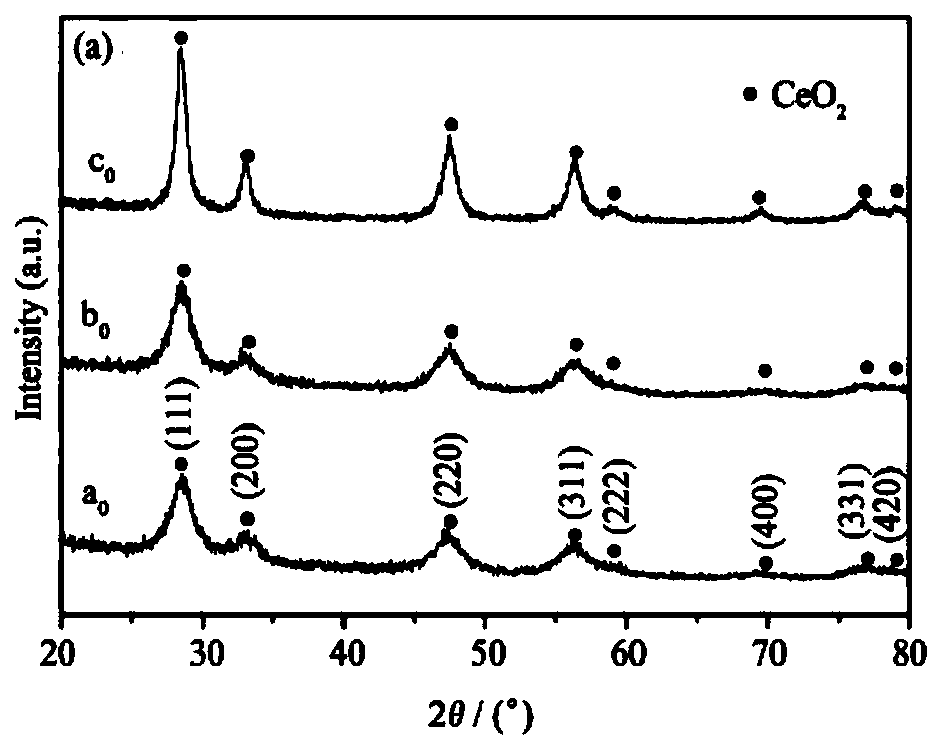

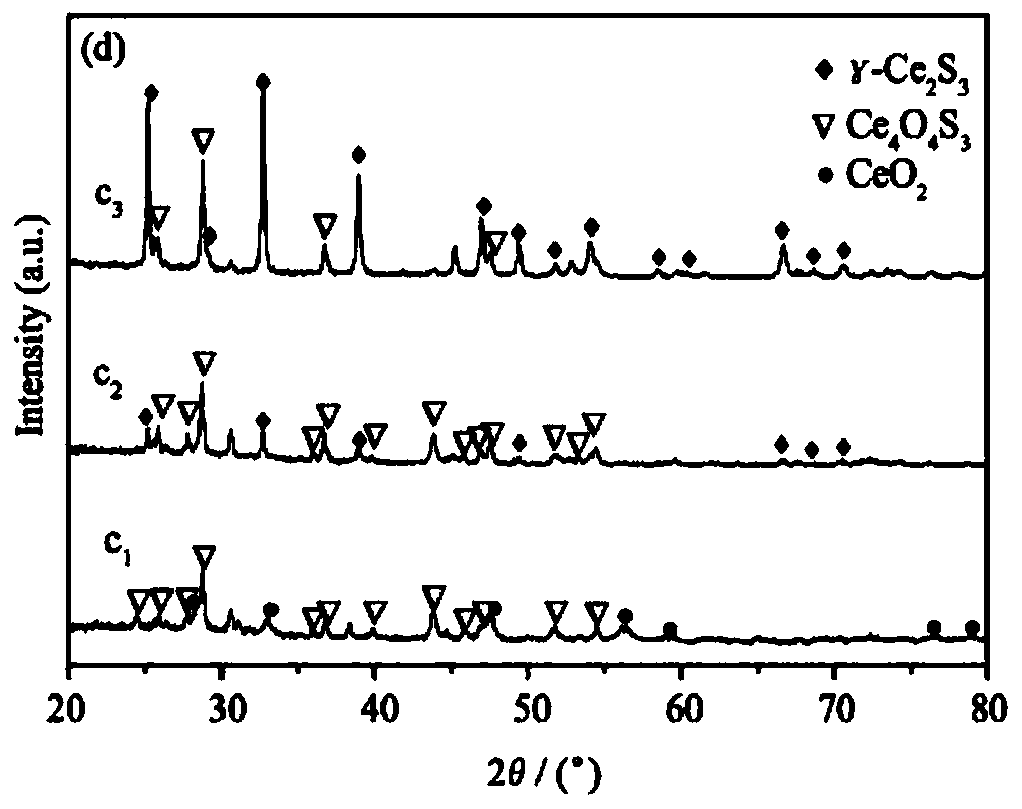

[0042] A kind of preparation method of novel rare earth red pigment γ-Ce2S3, including modified CeO2 Preparation of Composite Nano Precursor Powder and Red Pigment γ-Ce 2 S 3 calcination molding process;

[0043] The modified CeO 2 The preparation of composite nanometer precursor powder comprises the following steps:

[0044] a. Preparation of CeCl 3 solution and Na 2 S solution

[0045] Weigh 45gCeCl 3 , 90gNa 2 S·9H 2 O, 225ml (about 225g) of the first deionized water and 360ml (about 360g) of the second deionized water, and CeCl 3 、Na 2 S·9H 2 O was sequentially dissolved in the first deionized water and the second deionized water to obtain CeCl 3 solution and Na 2 S solution;

[0046] b. Preparation of CeO 2 Precursor sample

[0047] At room temperature, the above CeCl 3 The solution is added dropwise to Na at a rate of 0.5d / s 2 In the S solution, continue magnetic stirring until the precipitation reaction is complete. In the early stage of the reaction, a...

Embodiment 2

[0060] The modified CeO 2 The preparation of composite nanometer precursor powder comprises the following steps:

[0061] a. Preparation of CeCl 3 solution and Na 2 S solution

[0062] Weigh 50gCeCl 3 , 110gNa 2 S·9H 2 0. 300ml (about 300g) of the first deionized water and 500ml (about 500g) of the second deionized water, and CeCl 3 、Na 2 S·9H 2 O was sequentially dissolved in the first deionized water and the second deionized water to obtain CeCl 3 solution and Na 2 S solution;

[0063] b. Preparation of CeO 2 Precursor sample

[0064] At room temperature, the above CeCl 3 The solution is added dropwise to Na at a rate of 1d / s 2 In the S solution, continue magnetic stirring until the precipitation reaction is complete. In the early stage of the reaction, a white flocculent precipitate is rapidly produced, accompanied by the smell of rotten eggs (need to be connected to an exhaust gas absorption device). After filtering, washing and drying at room temperature for...

Embodiment 3

[0075] The modified CeO 2 The preparation of composite nanometer precursor powder comprises the following steps:

[0076] a. Preparation of CeCl 3 solution and Na 2 S solution

[0077] Weigh 50gCeCl 3 , 125gNa 2 S·9H 2 O, 350ml (about 350g) of the first deionized water and 600ml (about 600g) of the second deionized water, and CeCl 3 、Na 2 S·9H 2 O was sequentially dissolved in the first deionized water and the second deionized water to obtain CeCl 3 solution and Na 2 S solution;

[0078] b. Preparation of CeO 2 Precursor sample

[0079] At room temperature, the above CeCl 3 The solution is added dropwise to Na at a rate of 1.5d / s 2 In the S solution, continue magnetic stirring until the precipitation reaction is complete. In the early stage of the reaction, a white flocculent precipitate is rapidly produced, accompanied by the smell of rotten eggs (need to be connected to an exhaust gas absorption device). After filtering, washing and drying at room temperature f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com