Novel hot stamping die cooling pipe sealing device

A technology for hot stamping dies and sealing devices, applied in the directions of forming tools, manufacturing tools, transportation and packaging, etc., can solve the problems of water leakage at the interface of cooling pipes, affecting the life of the mold, affecting the cooling effect, etc., so as to prevent the change of water flow and prolong the life of the mold. , to ensure the effect of cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A novel cooling duct sealing device installed on a hot stamping die according to the present invention will be further described below with reference to the accompanying drawings.

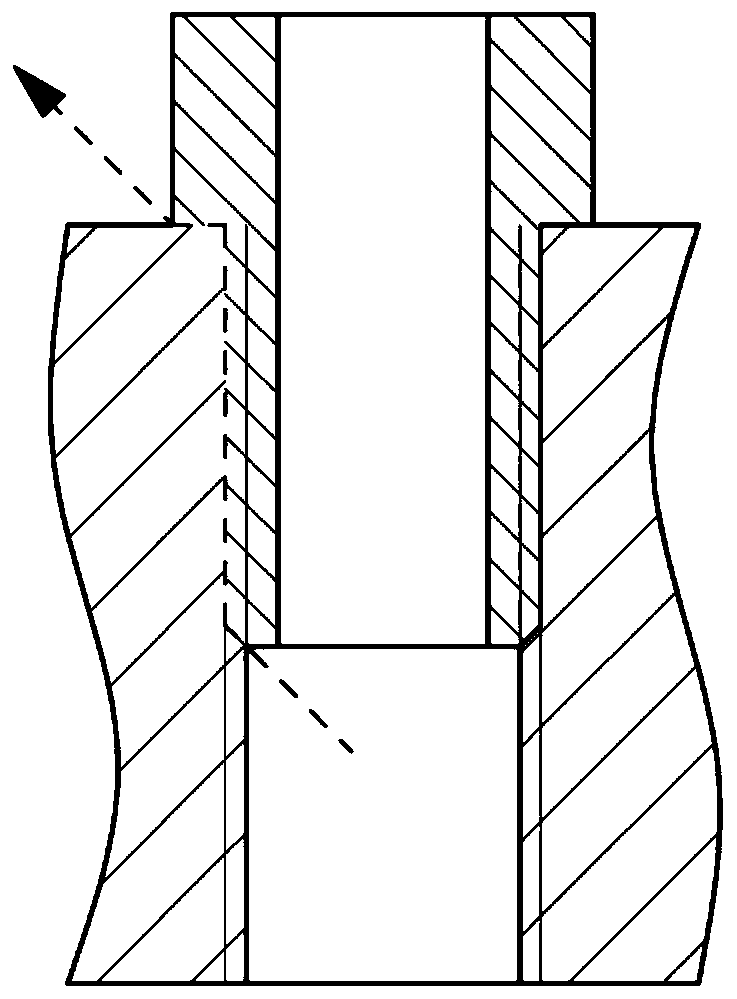

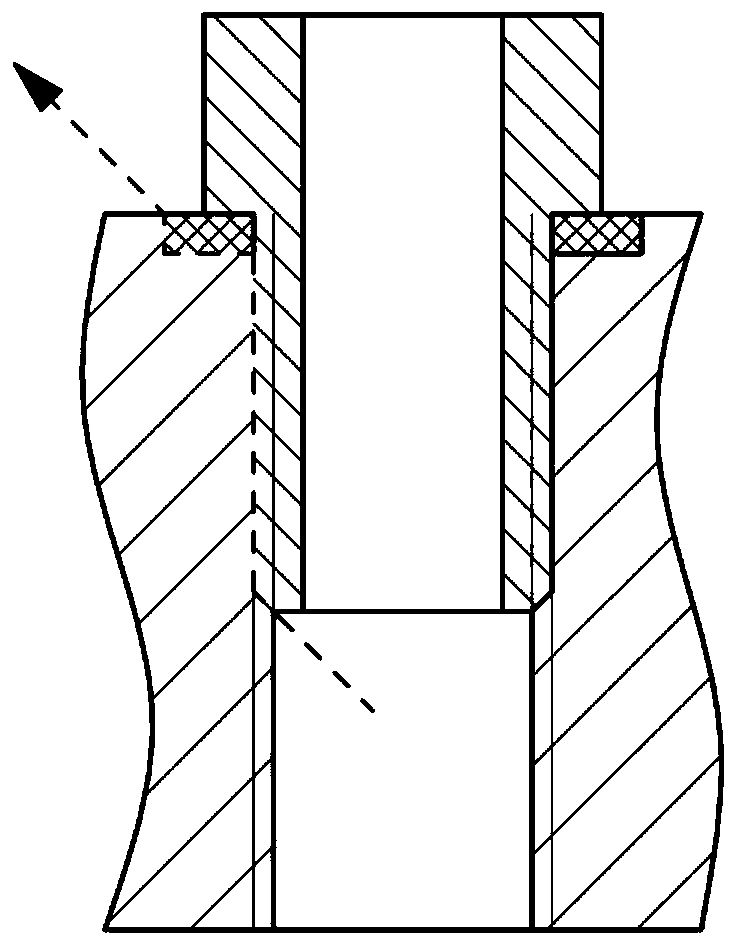

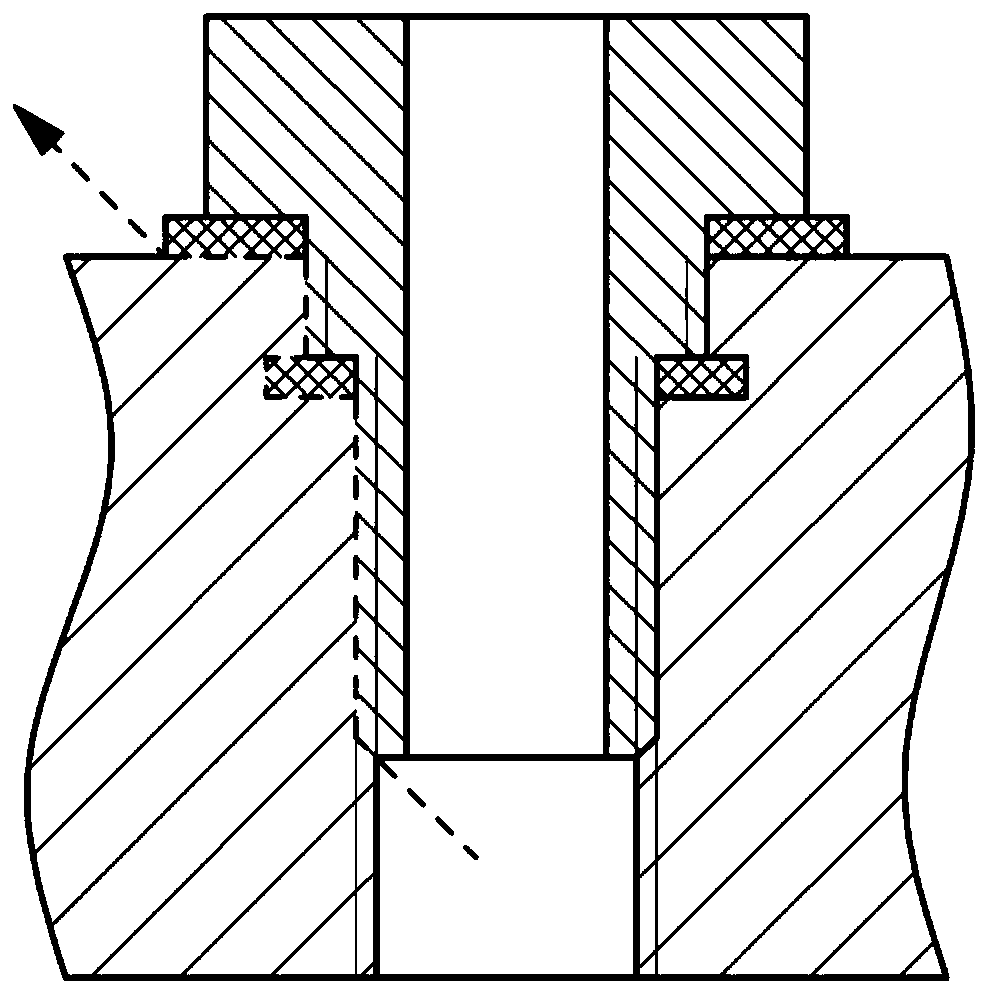

[0018] First, the sealing principle is explained, figure 1 , figure 2 , image 3 They are the structural diagrams and water leakage diagrams of three different sealing devices respectively, and the dotted lines in the figure are the water leakage routes. Such as figure 1 As shown, the pipe joint of the cooling pipe without a sealing ring is in direct contact with the mold interface, which requires extremely high matching precision between the two, and there is only one inflection in the leakage route, which is very prone to leakage problems; figure 2 As shown, the grooved single-seal cooling pipe is processed with a groove at the mold interface to place the seal ring, and the seal is achieved by pressing the seal ring. This sealing structure has a soft seal ring between the pipe joint a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com