Feeding bottle capable of realizing automatic cooling

An automatic cooling and feeding bottle technology, which is applied to feeding bottles and other directions, can solve problems such as difficult temperature, time-consuming, and affecting the baby's health, and achieve the effect of accelerating the flow of heat and dissipating heat quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

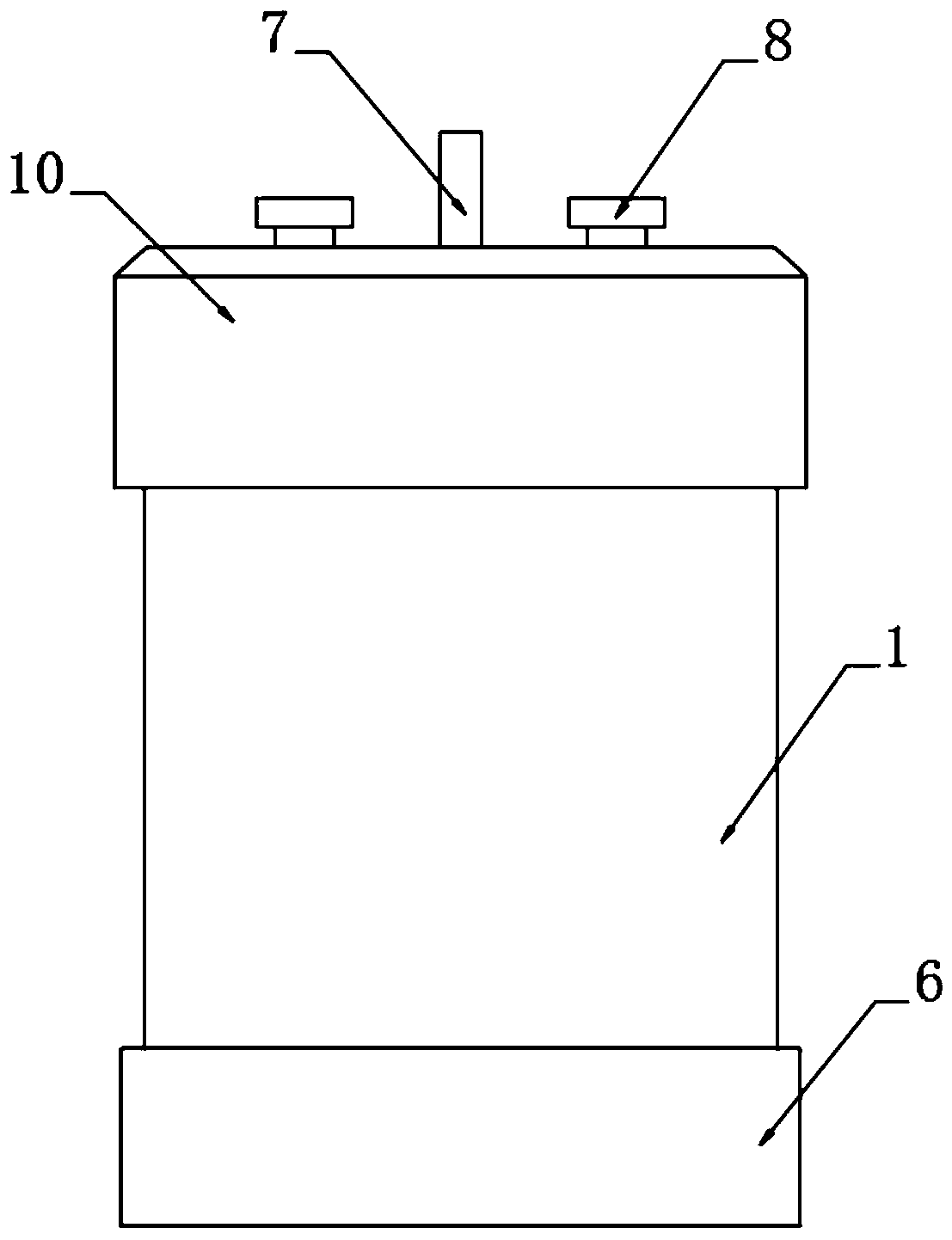

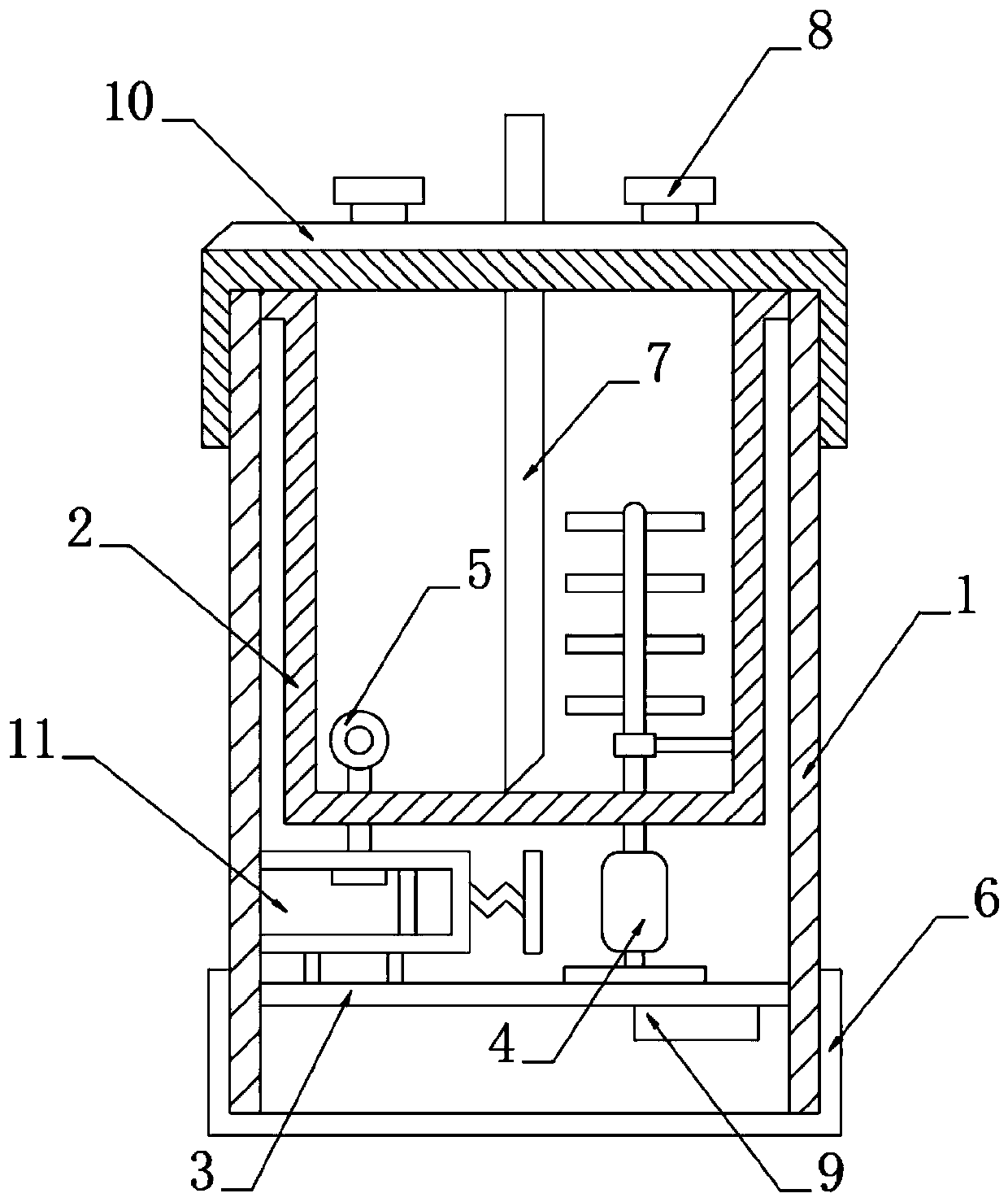

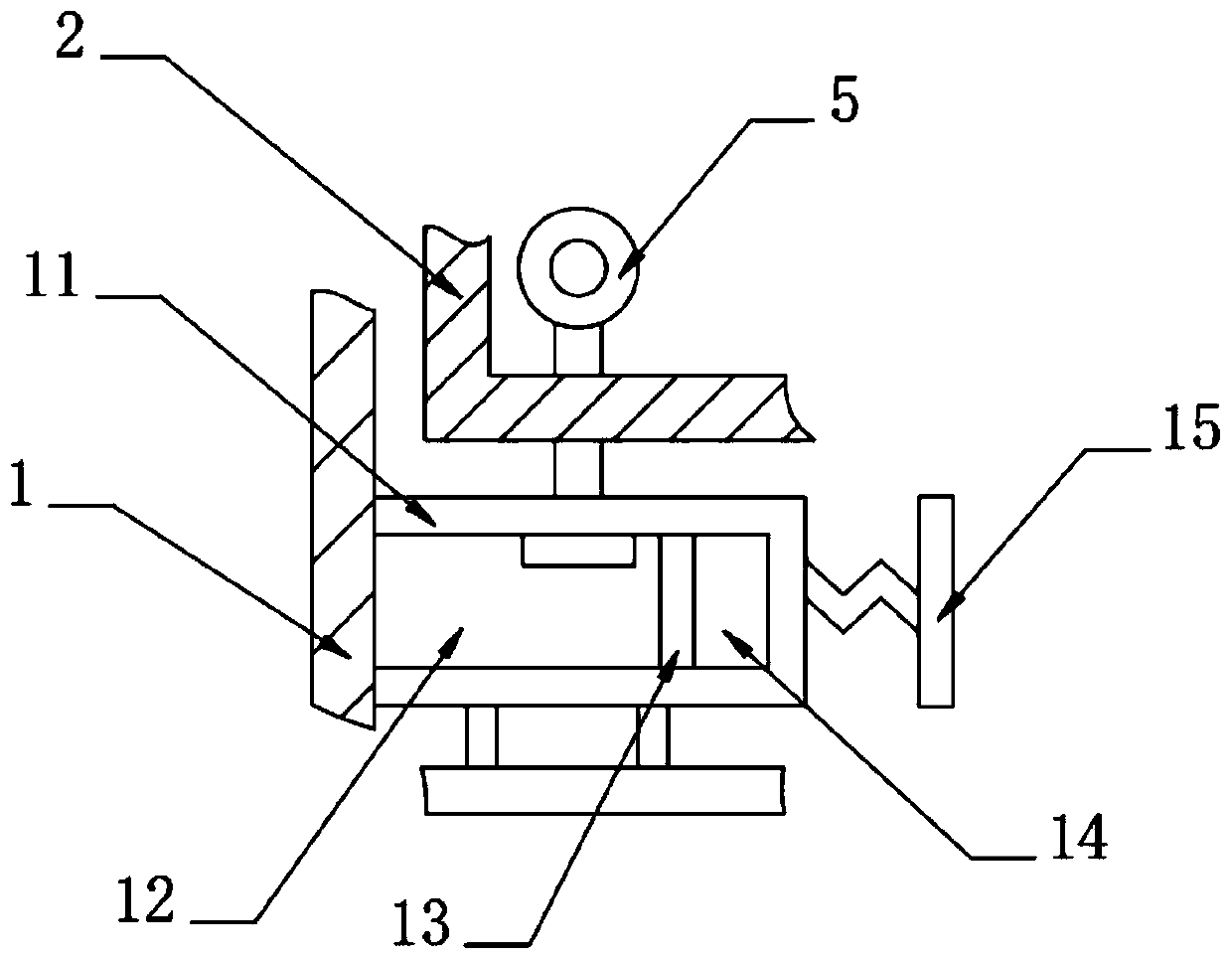

[0033] see Figure 1-2 , a feeding bottle that can realize automatic cooling, including a bottle body 1 and a bottle cap 10 screwed tightly above the bottle body 1, the exhaust mechanism includes an exhaust port arranged on the bottle cap 10, and the exhaust port is slidingly sealed and connected with a row When the gas cover 8 and the exhaust cover 8 are slidably connected to the exhaust port, the feeding bottle 2 can be separated from the outside world, and the dust can be reduced as far as possible from entering the feeding bottle 2. At the same time, when the exhaust cover 8 is opened, the stirring rod 16 rotates , the heat emitted in the milk can be discharged through the exhaust port to maintain the balance of the internal air pressure of the feeding bottle 2. The feeding bottle 2 is fixedly connected to the bottle body 1. The bottom of the feeding bottle 2 is in contact with the straw 7, and the upper end of the straw 7 runs through the bottle. The cover 10 extends outw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com