Wet diaphragm and preparation process thereof

A diaphragm and wet process technology, applied in the field of wet process diaphragm and its preparation, can solve the problems affecting the service life, the safety performance of high-power discharge, the large proportion of ceramic particles, and the inability to meet the market demand, etc. The effect of improved flatness, increased cost, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

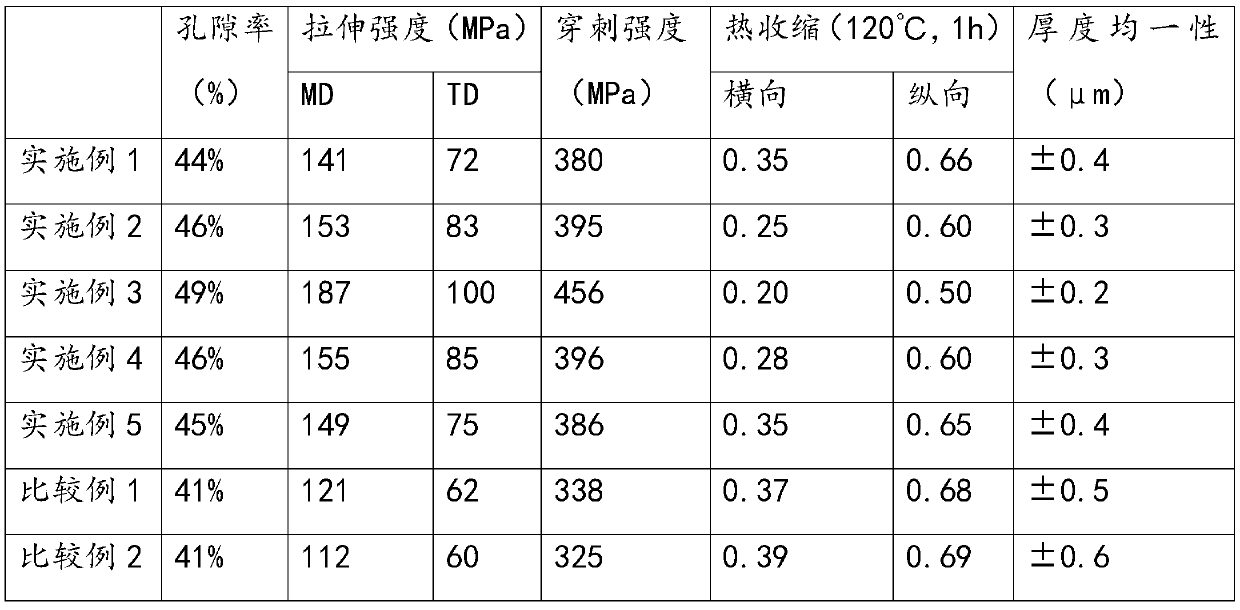

Examples

Embodiment 1

[0023] material:

[0024] 100Kg polyethylene (polyethylene particles are high-density polyethylene with a molecular weight of 300,000);

[0025] 100Kg glycerin (the mixing ratio of polyethylene and glycerin is 1:1);

[0026] The antioxidant 1010 of 1Kg (the quality of antioxidant accounts for 1% of polyethylene quality);

[0027] 0.1Kg of nano-ceramic powder (the quality of the anti-nano-ceramic powder accounts for 0.1% of the polyethylene mass, and the particle diameter is 800nm).

[0028] Preparation:

[0029] (1) take by weighing 100Kg polyethylene, the antioxidant 1010 of 1Kg and the nano ceramic powder of 0.1Kg and fully mix;

[0030] (2) Pass the mixed raw materials in step (1) through an extruder with a temperature of 200°C to obtain a high-temperature melt, weigh 100Kg of glycerol and put it into the extruder, fully mix the pore-forming agent with the high-temperature melt and Extruded through a twin-screw extruder, the extruded melt is rapidly cooled to 10°C to fo...

Embodiment 2

[0037] material:

[0038] 100Kg polyethylene (polyethylene particles are high-density polyethylene with a molecular weight of 450,000);

[0039] 210Kg of DBP (the mixing ratio of polyethylene and DBP is 1:2.1);

[0040] The antioxidant 1076 of 0.4Kg and the antioxidant 168 of 0.3Kg (the total mass of antioxidant accounts for 0.7% of polyethylene quality);

[0041] 0.3Kg of nano-ceramic powder (the quality of nano-ceramic powder accounts for 0.3% of polyethylene mass, particle diameter is 650nm);

[0042] Sodium polyacrylate of 0.1Kg (the quality of stabilizer accounts for 0.1% of the quality of polyethylene)

[0043] Preparation:

[0044] (1) take by weighing 100Kg polyethylene, the antioxidant 1076 of 0.4Kg and the antioxidant 168 of 0.3Kg and the nano ceramic powder of 0.3Kg, the sodium polyacrylate of 0.1Kg fully mix;

[0045] (2) Pass the mixed raw materials in step (1) through an extruder with a temperature of 220°C to obtain a high-temperature melt, weigh 210Kg of DB...

Embodiment 3

[0052] material:

[0053] 100Kg polyethylene (polyethylene particles are high-density polyethylene with a molecular weight of 600,000);

[0054] 320Kg paraffin oil (the mixing ratio of polyethylene and paraffin oil is 1:3.2);

[0055] The antioxidant 2246 of the antioxidant 264 of 0.1Kg, the antioxidant 1098 of 0.2Kg and 0.2Kg (the total mass of antioxidant accounts for 0.5% of polyethylene quality);

[0056] 0.5Kg of nano-ceramic powder (the quality of anti-nano-ceramic powder accounts for 0.5% of the polyethylene mass, and the particle diameter is 450nm);

[0057] 0.2Kg of sodium hexametaphosphate and 0.1Kg of polyvinyl alcohol (the total mass of the stabilizer accounts for 0.3% of the polyethylene mass).

[0058]Preparation:

[0059] (1) Take by weighing 100Kg polyethylene, 0.1Kg of antioxidant 264, 0.2Kg of antioxidant 1098, 0.2Kg of antioxidant 2246, 0.5Kg of nano-ceramic powder, 0.2Kg of sodium hexametaphosphate and 0.1Kg The polyvinyl alcohol is fully mixed;

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com