Central heating system on-demand precise regulation and control method based on models

A central heating and model technology, applied in heating systems, heating methods, household heating, etc., can solve problems such as low utilization efficiency and energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

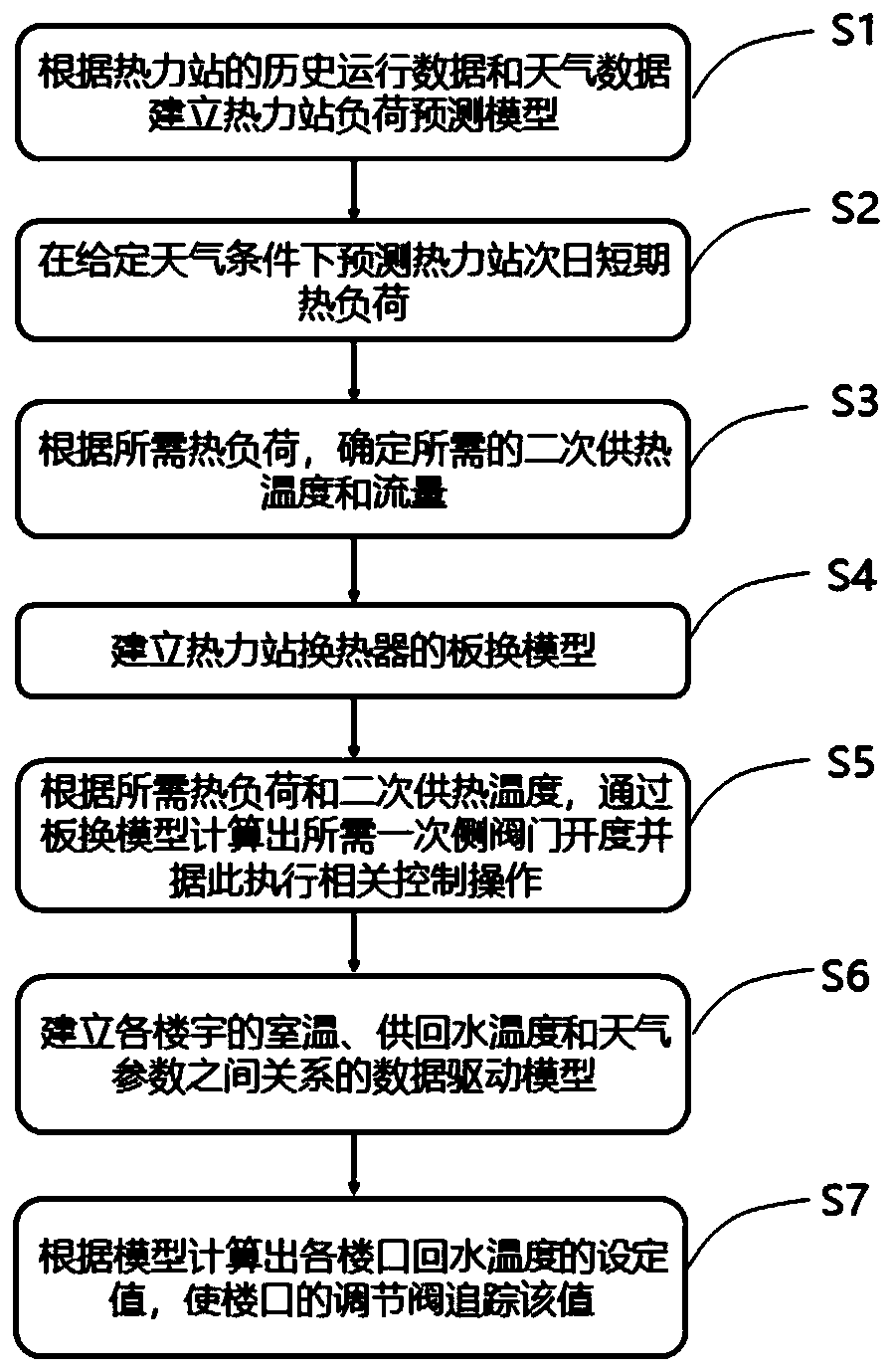

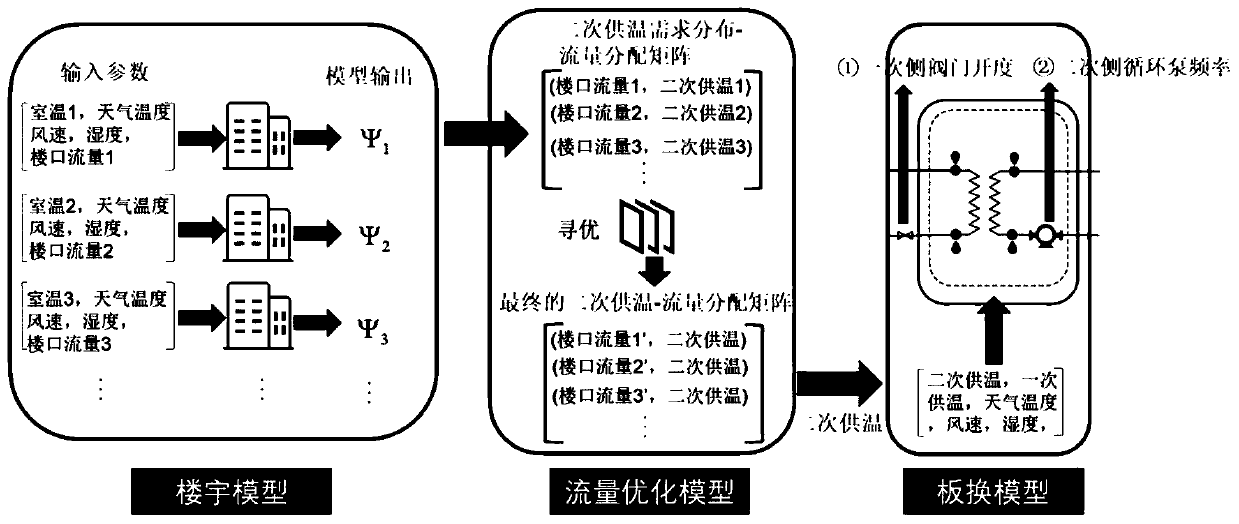

[0067] A model-based on-demand precise control method for central heating systems of the present invention comprises the following steps:

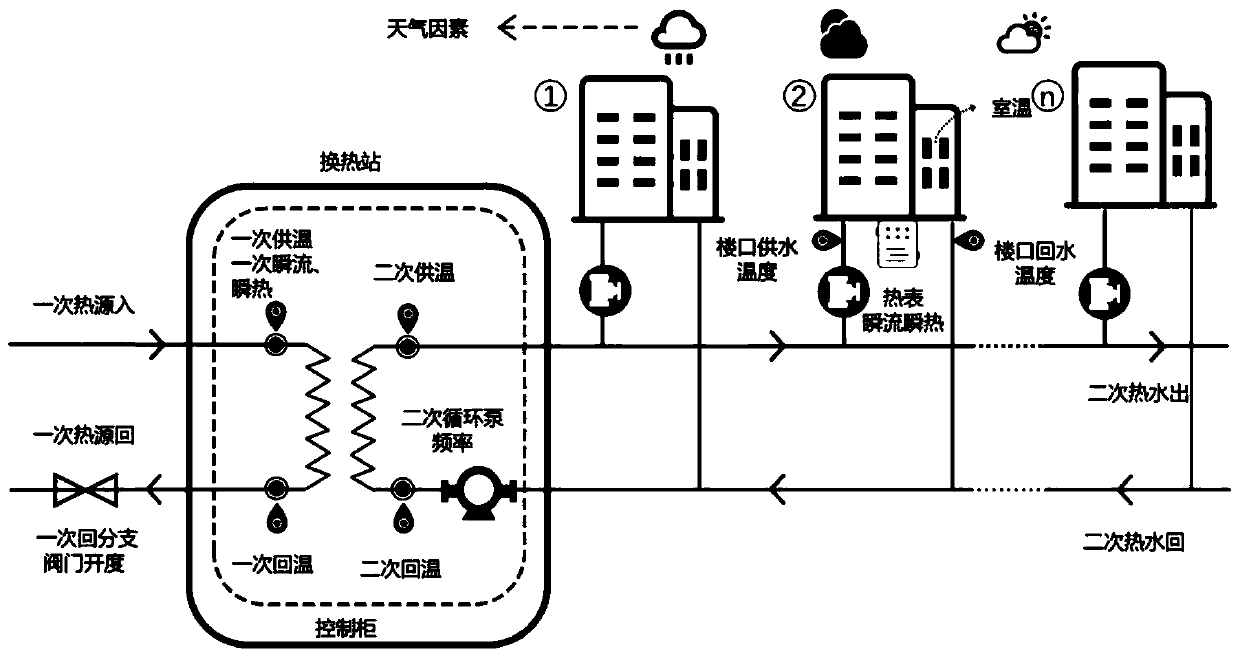

[0068] Step S1, such as figure 2 , based on the historical operation data and weather data of the thermal station, the load forecasting model of the thermal station is established. The historical operation data of the thermal station includes the secondary side temperature supply t 供2 , Secondary side return temperature t 回2 and secondary flow q 二次 etc. Regional weather parameters W include historical data such as temperature t, humidity d, light r and wind speed v, etc., based on which a load forecasting model is established.

[0069] The thermal load of the thermal station can be expressed as:

[0070] Ψ=cρq 二次 (t 供2 -t 回2 )

[0071] Use the data mining algorithm (taking SVR algorithm as an example) to mine the above-mentioned historical data set, that is to train the load forecasting model of the thermal station. Choose Ψ=cρq ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com