Arrangement and construction method of special roadway for withdrawing working face of coal mining area

A construction method and technology of working face, applied in tunnels, ground mining, tunnel lining, etc., can solve problems such as large resource loss, obvious impact, large coal pillar size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The layout and construction method of a special roadway for retraction of a working face in a coal mining area is as follows:

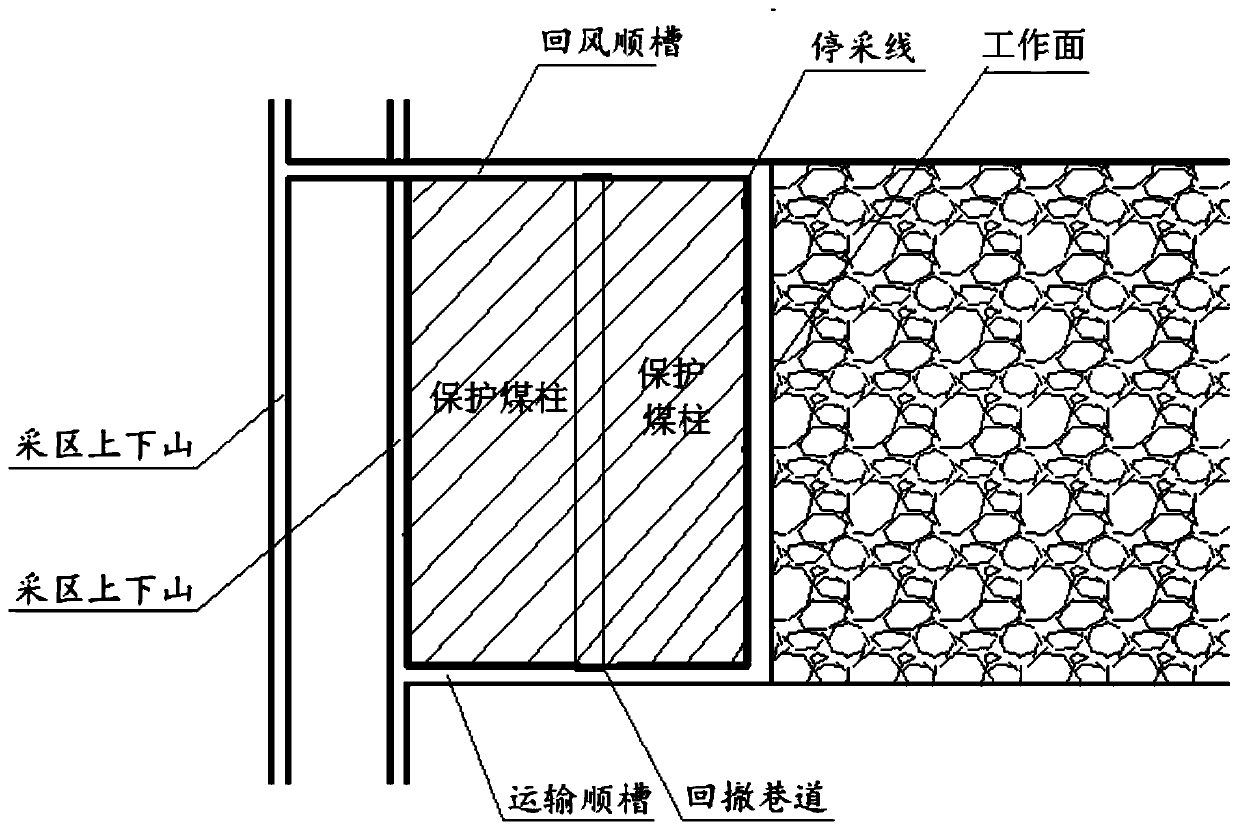

[0026] first step, such as figure 1 As shown, in the middle position between the upper and lower hills of the mining area and the production stop line of the working face, a roadway parallel to the upper and lower hills of the mining area is arranged as the withdrawal roadway.

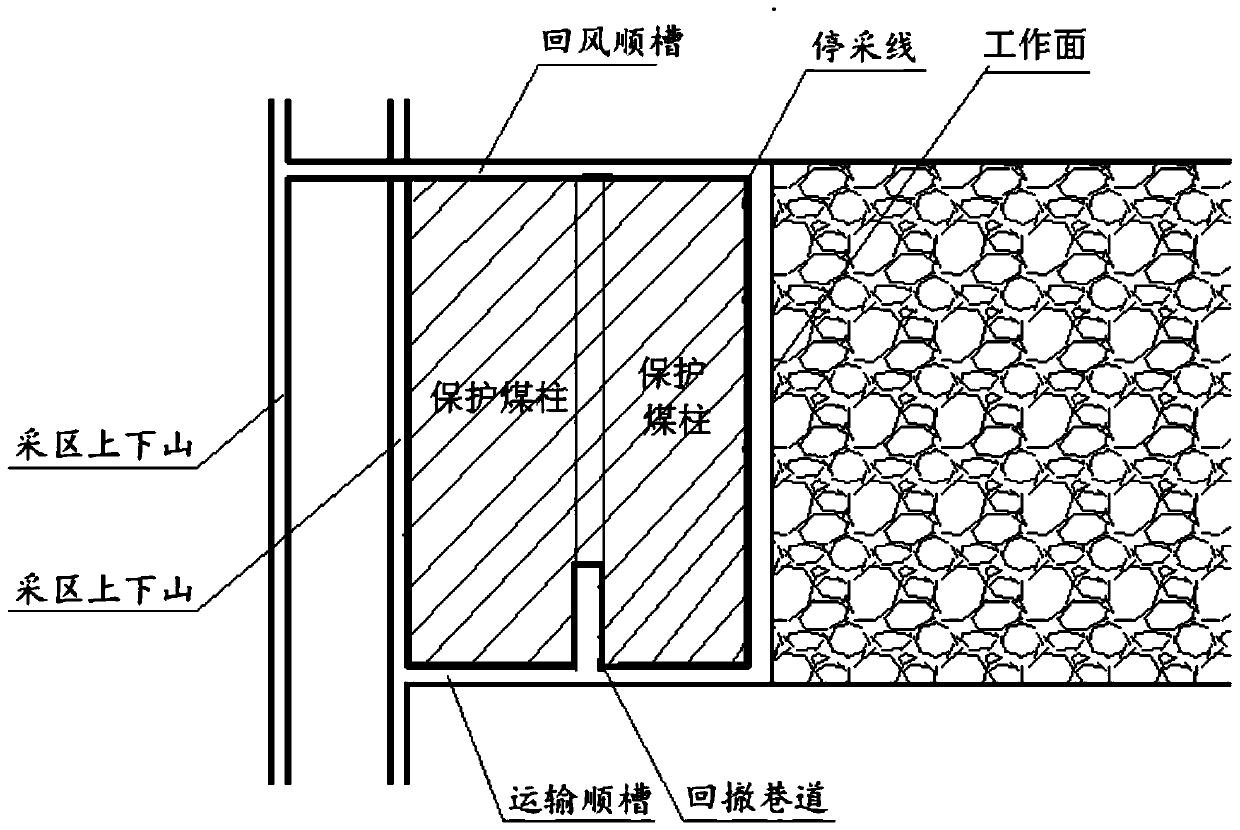

[0027] The second step, such as figure 2 As shown, adopt the existing method of tunneling up and down the mountain roadway to excavate the retraction roadway, and the excavation direction starts from the transportation trough to the return wind trough;

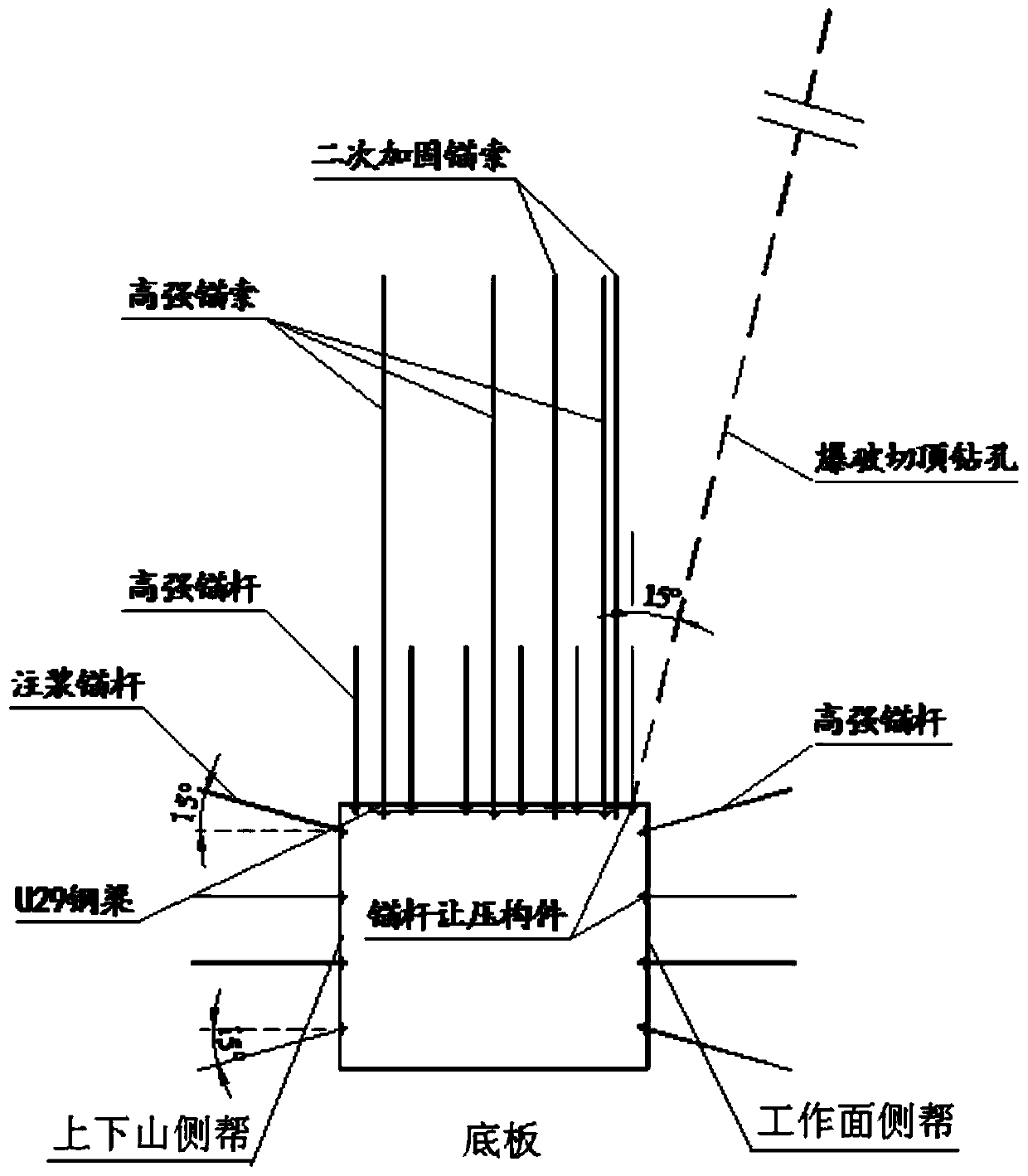

[0028] The third step, such as image 3 As shown, the retraction roadway is excavated and supported at the same time; the initial support method is as follows image 3 As shown, the sides of the upper and lower hills are supported by prestressed bolts and reinforced by grouting; Support method; details are as follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com