Self-checking common hydrogen-secondary hydrogen conversion device

A conversion device and self-checking technology, applied in measuring devices, hydrogen, instruments, etc., can solve the problems of complex equipment and cost, inability to detect purity at any time, difficult to measure ortho-parahydrogen molecules, etc., and achieve the effect of convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

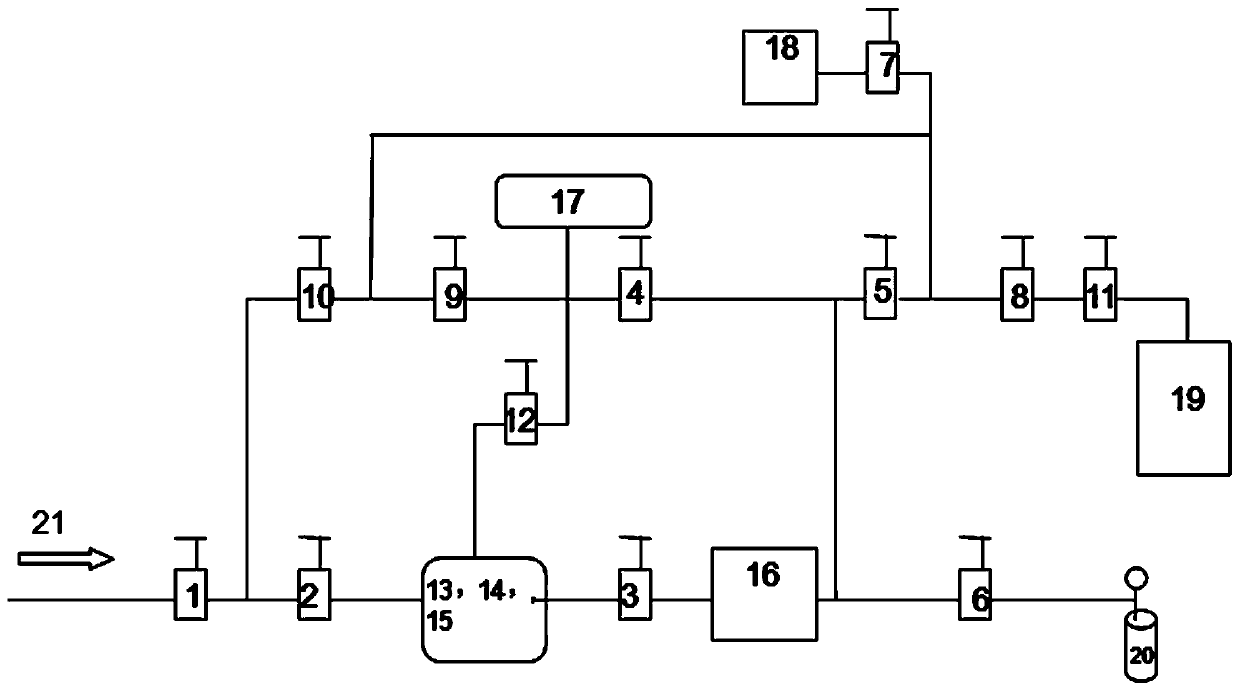

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

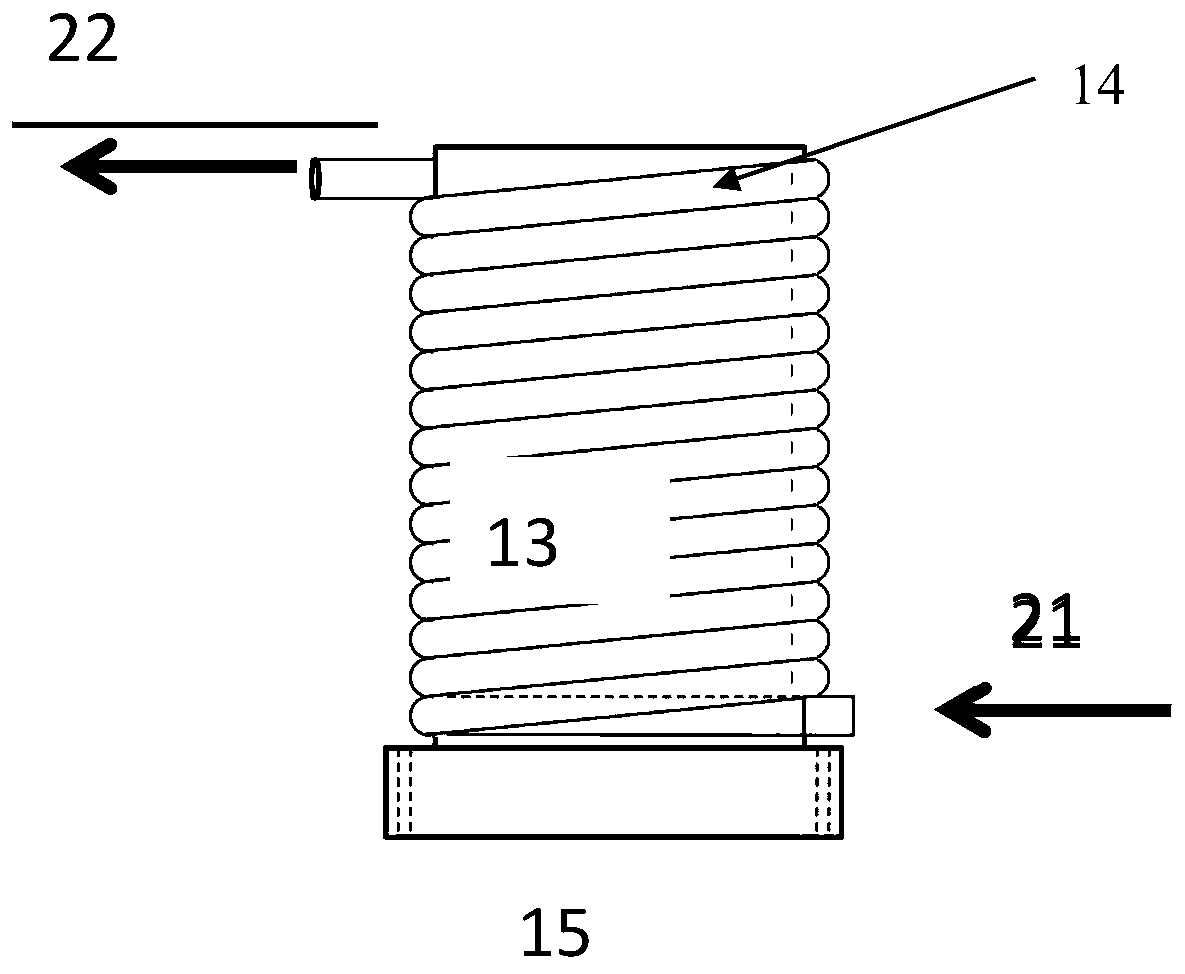

[0034] The detailed structure of the cold pump catalyst is as follows: figure 2 As shown, the copper tube containing the catalyst is wound around the cold head of the cold pump, and the low-temperature working environment of the catalyst is realized by contacting the working cold head. The catalyst needs to be below 25K to effectively realize the catalytic function, where the cold head and pipeline are located in the vacuum environment of the cold pump. The catalyst in the pipeline is in an independent vacuum pipeline environment. Among them, the cold pump is Austin Scientific model M600, and the catalyst is Fe 3 o 4 , and its size is about 1mm powder.

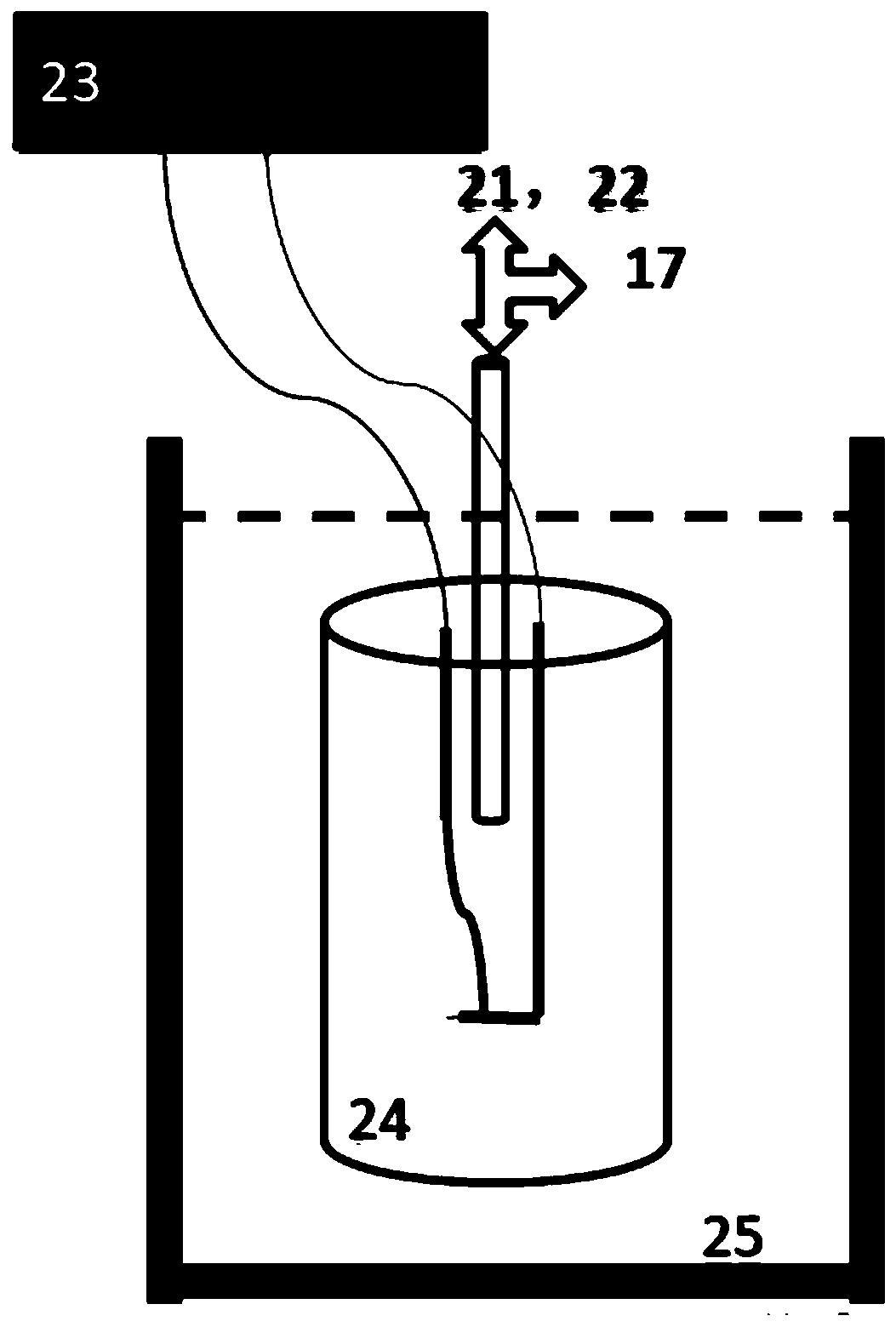

[0035] The design of the test device for hydrogen gas is as follows: image 3 As shown, the principle of temperature measurement is that at low temperature (100 ~ 200K), the thermal cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com