Design method, manufacturing method and system for digital shell-shaped dental appliance

A technology for a dental appliance and a design method, which is applied in the field of dental orthodontics, can solve the problems that shell-shaped dental appliances cannot be fully automated and standardized production, achieve automatic preparation, avoid manual undercut filling, and improve production efficiency and quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

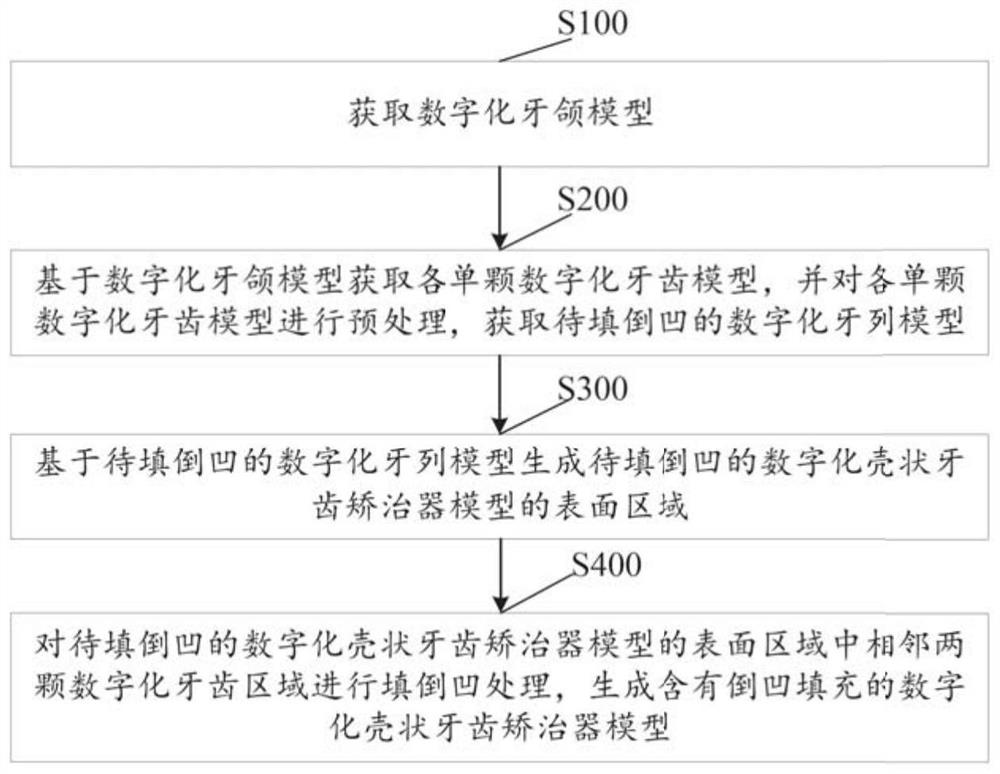

[0082] This embodiment provides a digital shell-shaped dental appliance design method, the flow chart of which is as follows figure 1 As shown, it specifically includes the following steps.

[0083] S100: Obtain a digital dental model;

[0084] S200: Obtain each single digital tooth model based on the digital jaw model, and perform preprocessing on each single digital tooth model to obtain a digital dentition model to be filled with undercuts;

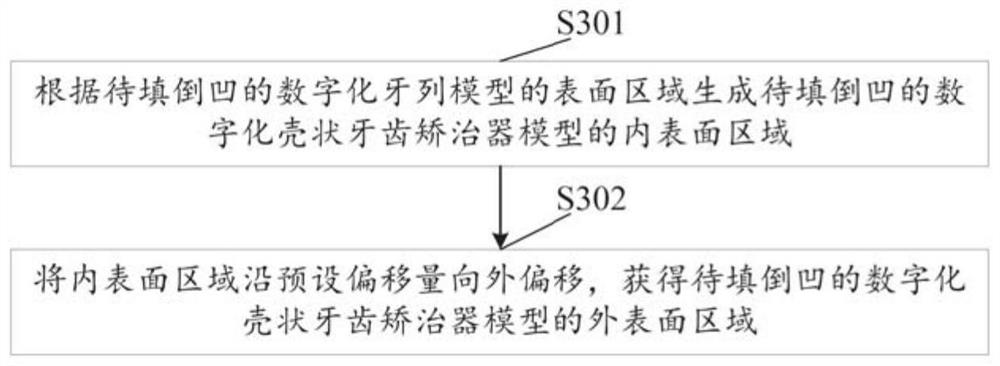

[0085] S300: Generate the surface area of the digital shell-shaped dental appliance to be filled with the undercut based on the digital dentition model of the undercut to be filled;

[0086] S400: Perform undercut filling processing on two adjacent digitized tooth regions in the surface area of the digital shell-shaped dental appliance to be filled with undercuts, and generate a digital shell-shaped dental appliance containing undercut filling.

[0087] Through the above steps S100-S400, a digital shell-shaped dental appliance wi...

Embodiment 2

[0154] Based on Embodiment 1, this embodiment provides a digital shell-shaped dental appliance design system, the principle diagram of which is as follows Figure 6 As shown, it includes an acquisition module 100 , a preprocessing model 200 , a generation module 300 and an undercut filling module 400 .

[0155] Wherein, the obtaining module 100 is used to obtain a digital dental model, for example, the obtaining model 100 may be an intraoral scanner, which directly obtains the actual digital dental model in the patient's mouth.

[0156] The preprocessing module 200 is used to obtain each single digital tooth model based on the digital jaw model, and perform preprocessing on each single digital tooth model to obtain a digital dentition model to be filled with undercuts.

[0157] Specifically, the preprocessing module 200 includes a segmentation unit 201 and a preprocessing unit 202, wherein the segmentation unit 201 is used to perform segmentation processing on each single digi...

Embodiment 3

[0169] Based on Embodiment 1, this embodiment provides a method for designing a shell-shaped dental appliance, the flow chart of which is as follows Figure 7 As shown, it specifically includes the following steps.

[0170] S700: Obtain a digital dental model, where the digital dental model includes a digital dentition model.

[0171] S701: Design the orthodontic target position on the digital dentition model, and design a series of digital dentition models to be filled with undercuts gradually moving from the initial position to the orthodontic target position.

[0172] S702: Generate the surface area of the digital shell-shaped dental appliance to be filled with undercuts based on the digital dentition model of the undercuts to be filled.

[0173] S703: Perform undercut filling processing on two adjacent digitized tooth regions in the surface area of the digital shell-shaped dental appliance to be filled with undercuts to generate a digital shell-shaped dental appliance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com