Vacuum induction brazing device and use method thereof

A vacuum induction and brazing technology, used in electric heating devices, auxiliary devices, welding equipment, etc., can solve the problems of long heating time in vacuum brazing, oxidation tendency of welded parts, low brazing efficiency, etc., and achieve fast and pollution-free welding. , convenient operation, reasonable structure design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

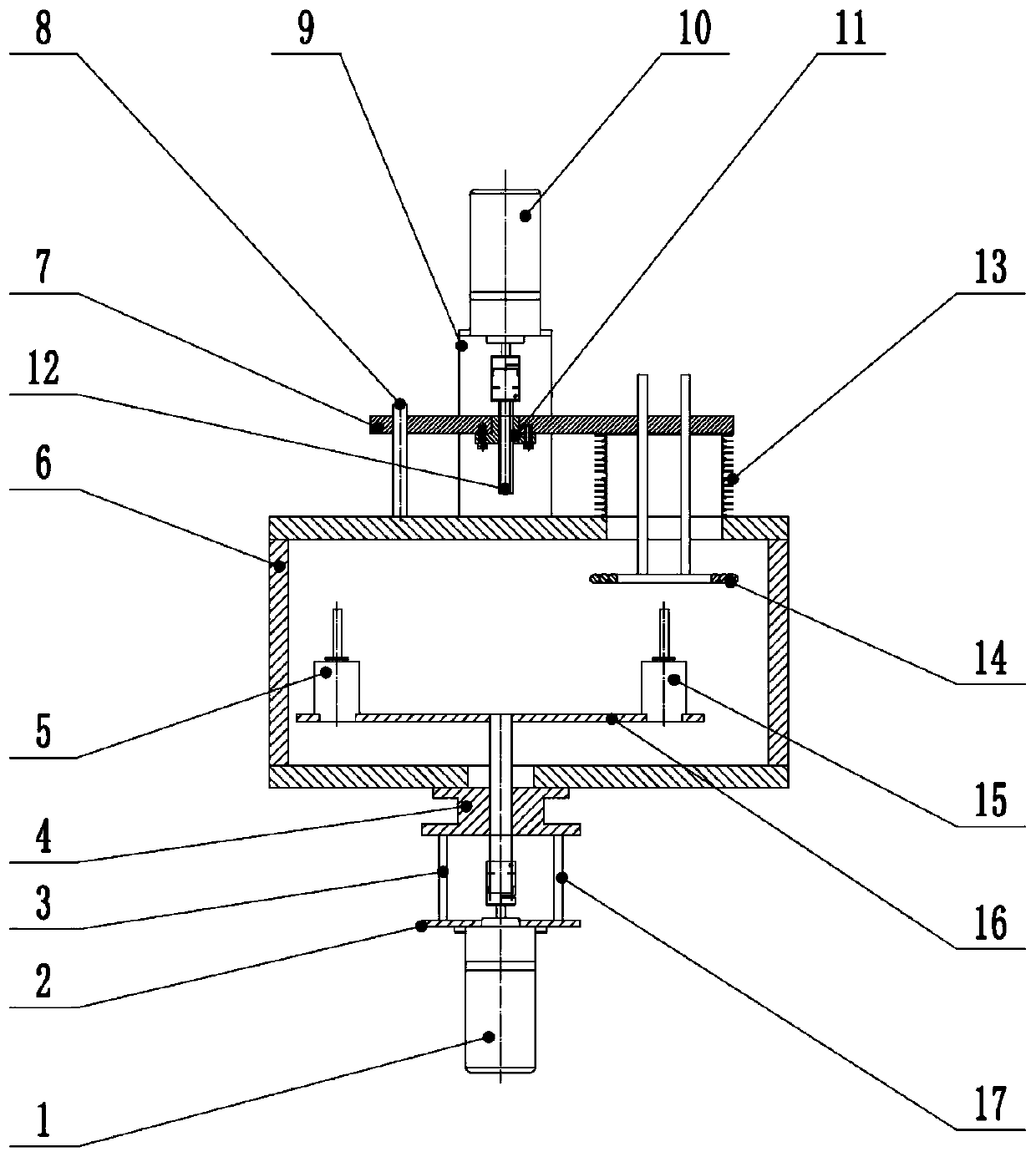

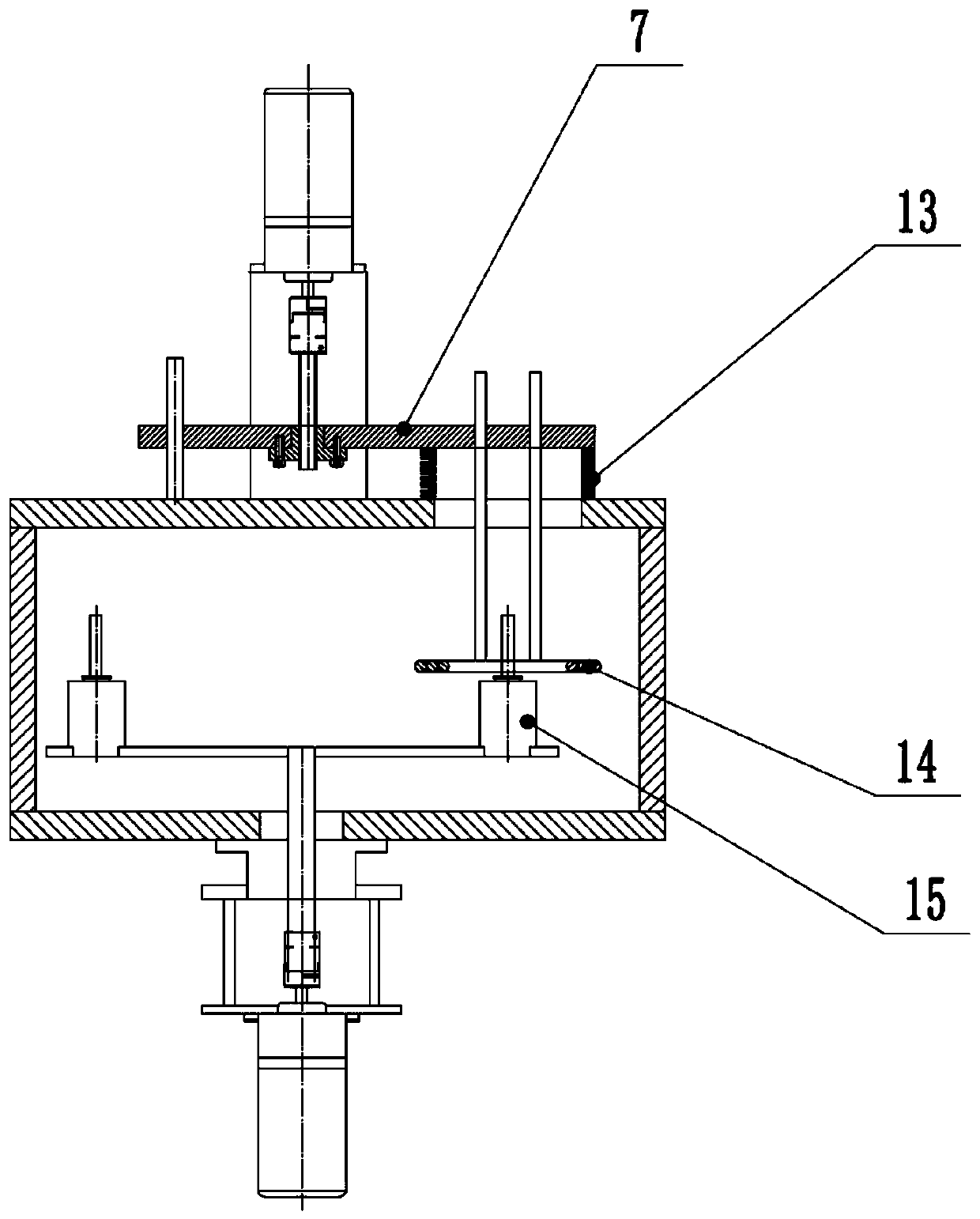

[0023] Attached below Figure 1-3 A vacuum induction brazing device and its application method of the present invention are described in detail.

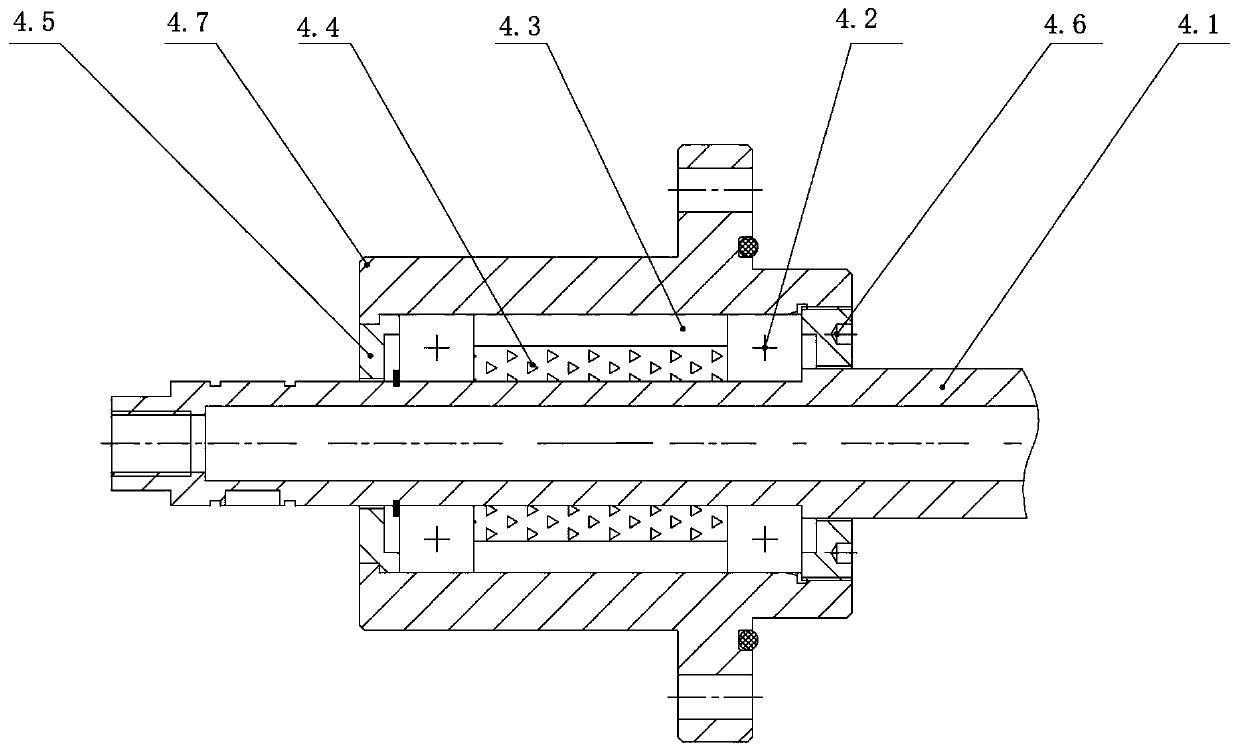

[0024] A vacuum induction brazing device, the vacuum induction brazing device includes a rotating motor 1, a rotating motor fixing plate 2, a support rod A3, a magnetic fluid 4, a workpiece A5, a vacuum chamber 6, a lifting adjustment plate 7, a guide rod 8, a lifting Motor fixing plate 9, lifting motor 10, lifting nut 11, screw mandrel 12, welding bellows 13, induction coil 14, workpiece B15, rotating sample table 16, pole B17; The bottom surface of the plate; the top surface of the rotating motor fixed plate is connected with the magnetic fluid through the parallel set of poles A and B; the magnetic fluid is fixed on the bottom of the vacuum chamber; the rotating sample stage is fixed on the magnetic fluid axis and located in the vacuum chamber; the workpiece A and the workpiece B are symmetrically arranged at the left and right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com