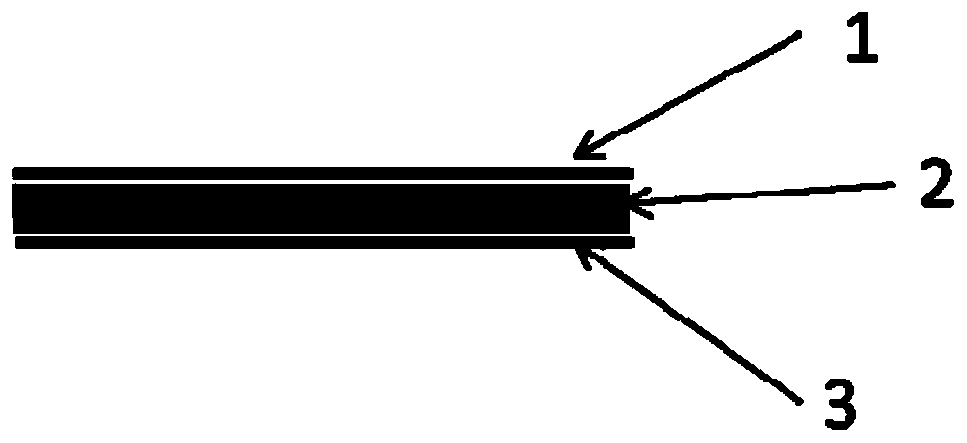

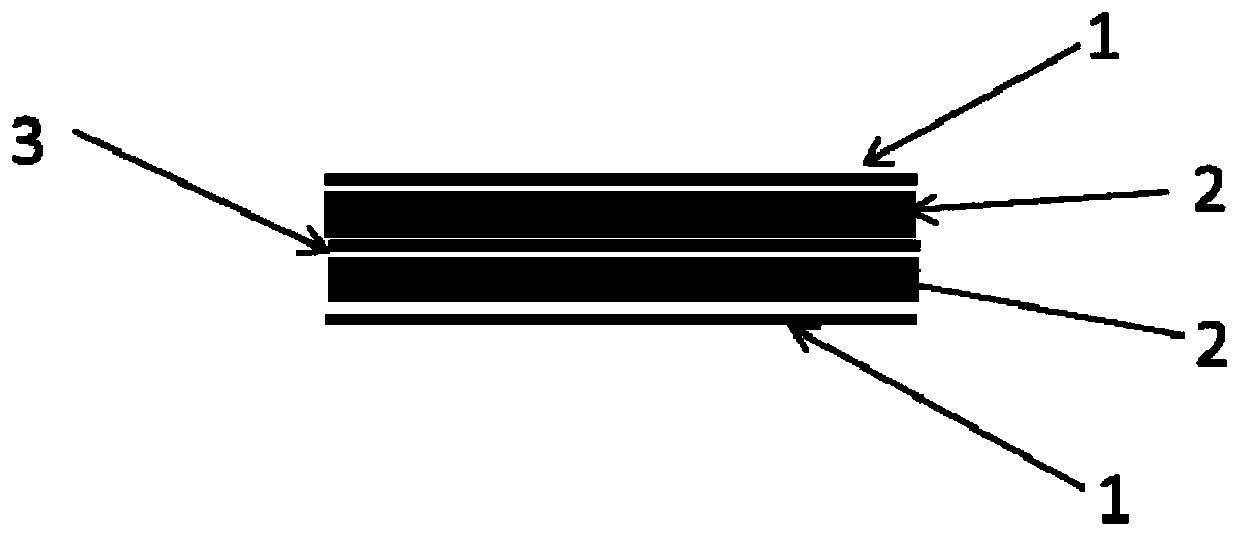

Laminated monopole plate and preparation method thereof, laminated bipolar plate comprising laminated monopole plate and application of laminated bipolar plate

A unipolar plate, stacked technology, applied in the direction of final product manufacturing, fuel cell parts, sustainable manufacturing/processing, etc., can solve the problems of reducing the thickness of the plate, hydrogen permeation of the carbon-based material plate, etc., to reduce Thickness, avoidance of hydrogen permeation, effect of high softening temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] A laminated bipolar plate, the preparation method is as follows:

[0072] (1) Preparation of composite carbon powder

[0073] Put 80 parts of artificial graphite with a D90 of 70 μm, 15 parts of polyvinylidene fluoride, and 5 parts of weather-grown carbon fiber into a Henschel mixer and stir for 20 minutes at 2000 r / min;

[0074] (2) Preparation of composite material layer

[0075] Put 20 parts of polyethylene terephthalate fibers into a planetary mixer with 1000 parts of deionized water, stir for 10 minutes at 1500r / min, then put 5 parts of weather-grown carbon fibers into the planetary mixer , stirred for 10min under the condition of 2000r / min, then put 2 parts of Super-P and 73 parts of artificial graphite powder with D90 of 70μm into the planetary mixer, continued stirring for 30min under the condition of 2000r / min, and poured the stirred slurry Put it into a 1000-mesh sieve, drain the liquid water, then put it into a vacuum oven, evacuate to -0.09MPa, and heat it...

Embodiment 2

[0081] A laminated bipolar plate, the preparation method is as follows:

[0082] (1) Preparation of composite carbon powder

[0083] Put 70 parts of artificial graphite with a D90 of 60 μm, 20 parts of polyvinylidene fluoride, and 10 parts of weather-grown carbon fiber into a Henschel mixer and stir for 30 minutes at 2000 r / min;

[0084] (2) Preparation of composite material layer

[0085] Same as Example 1

[0086] (3) Preparation of stacked bipolar plates

[0087] According to the order from bottom to top, the 3mm thick composite material layer, the 0.03mm thick aluminum alloy sheet, the 3mm thick composite material layer, and the 2mm thick composite carbon powder layer are stacked in sequence, and then put them into the molding flow In the mold of the road, and apply a pressure of 35MPa, while heating to 270 ℃, keep for 3min;

[0088] Then take out the formed unipolar plate, and use a sandblasting machine to treat the surface on the side with the flow channel for 2 minu...

Embodiment 3

[0090] A laminated bipolar plate, the preparation method is as follows:

[0091] (1) Preparation of composite carbon powder

[0092] Put 75 parts of artificial graphite with a D90 of 70 μm, 15 parts of polyvinylidene fluoride, and 10 parts of weather-grown carbon fiber into a Henschel mixer and stir for 30 minutes at 2000 r / min;

[0093] (2) Preparation of composite material layer

[0094] Put 15 parts of polyethylene terephthalate fibers into a planetary mixer with 1000 parts of deionized water, stir for 10 minutes at 1500r / min, then put 10 parts of weather-grown carbon fibers into the planetary mixer , stirred for 10min under the condition of 2000r / min, then put 5 parts of Super-P and 70 parts of artificial graphite powder with D90 of 70μm into the planetary mixer, continued stirring for 30min under the condition of 2000r / min, and poured the stirred slurry Put it into a 1000-mesh sieve, drain the liquid water, then put it into a vacuum oven, evacuate to -0.09MPa, and heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com