A robot servo control system for automatic loading of bagged cement

A servo control system and robot technology, applied in the direction of electric speed/acceleration control, transportation and packaging, object destacking, etc., to achieve high loading efficiency, promote automation development, and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] DETAILED DESCRIPTION OF THE INVENTION The technical solutions of the present invention will be further described in detail. This example is a preferred embodiment of the present invention, but the scope of the invention is not limited to the following examples.

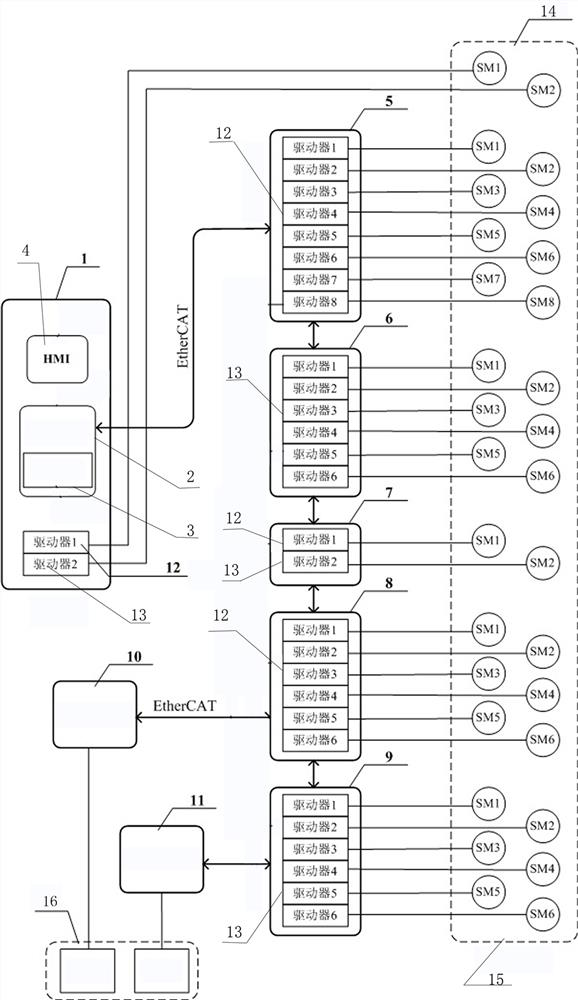

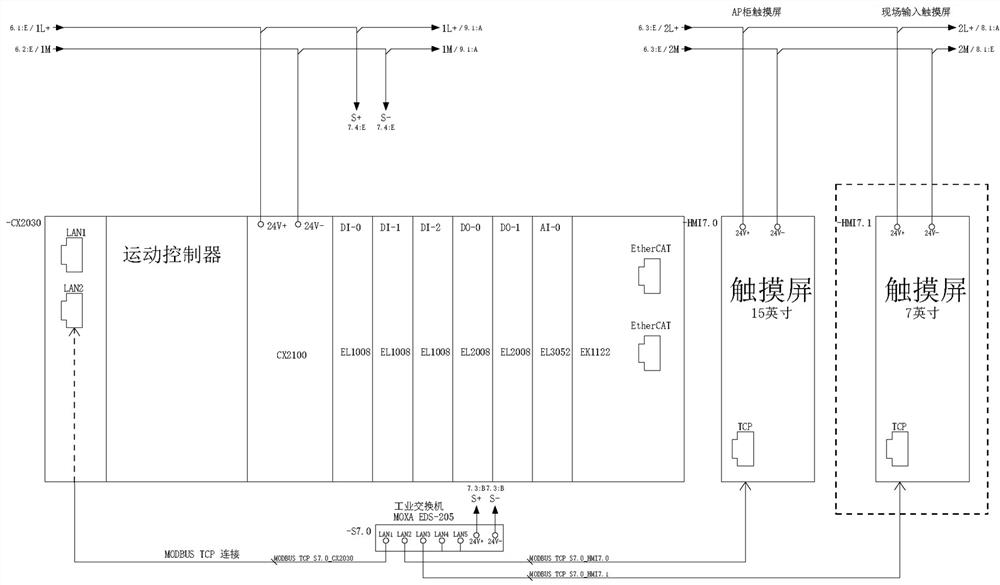

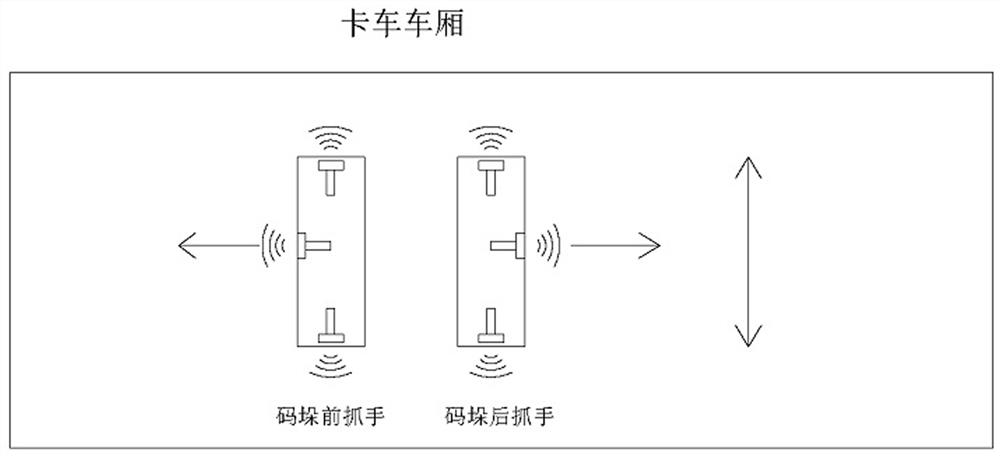

[0031] A sacking cement automatic loading robot servo control system, including a large truss, two sets of overalls, two sets of grabbed palletizing robots, as well as a servo control system in combination with palletizing robots, which servo control The system includes main power cabinet 1, main controller 2, man-machine interface HMI4, first large car electric control cabinet 5, second large car electric control cabinet 6, big car base electric control cabinet 7, first train electric control cabinet 8 , The second small car electric control cabinet 9, the first small car expansion box 10, the second carrier 12, the second driver 13, the first servo motor 14, the second servo motor 15, and the sensor set 16; HMI4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com