Air pressure environment simulation system and method at different altitudes for braking performance test

A braking system and environment simulation technology, applied in vehicle testing, machine/structural component testing, measuring devices, etc., can solve the problems of safety risks in the test process, no fixed test site, prone to altitude sickness, etc. The effect of shortening the development verification cycle, avoiding the risk of traffic accidents, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

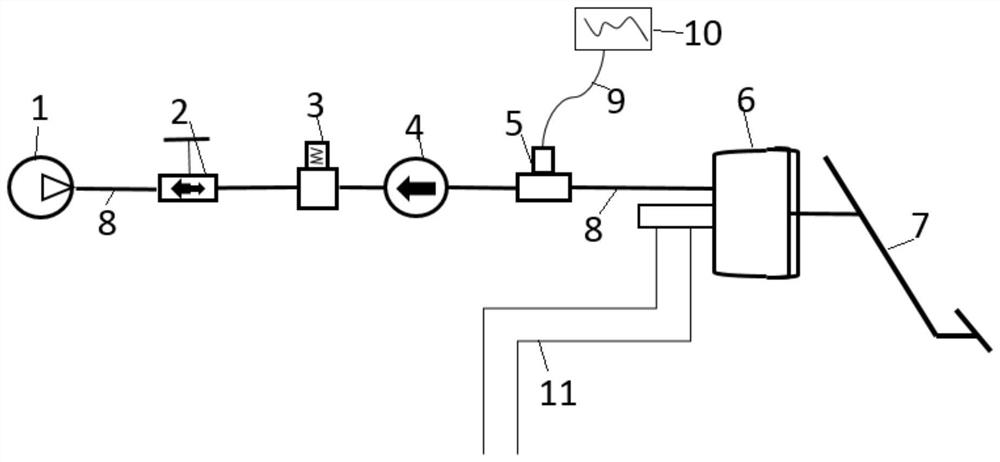

[0027] Such as figure 1 The air pressure environment simulation system at different altitudes for the braking performance test is shown, which includes the vacuum source 1 of the braking system, the check valve 4, the vacuum booster and the brake master cylinder assembly 6, the vacuum booster and the brake master The booster input push rod of the cylinder assembly 6 is equipped with a brake pedal 7, and the brake pedal 7 controls the brake oil pressure in the brake oil pipe 11 through the vacuum booster and the brake master cylinder assembly 6, thereby controlling the brake pressure. Effect, the suction end of the brake system vacuum source 1 is connected to the output end of the one-way valve 4, and the input end of the one-way valve 4 is connected to the vacuum booster and the brake booster air chamber of the brake master cylinder assembly 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com