Heating control method of gas water heater

A gas water heater and heating control technology, applied in fluid heaters, lighting and heating equipment, etc., can solve the problems of increasing the risk of blowing out flames, increasing manufacturing costs, affecting user experience, etc. Large temperature adjustment range, flexible and reliable control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

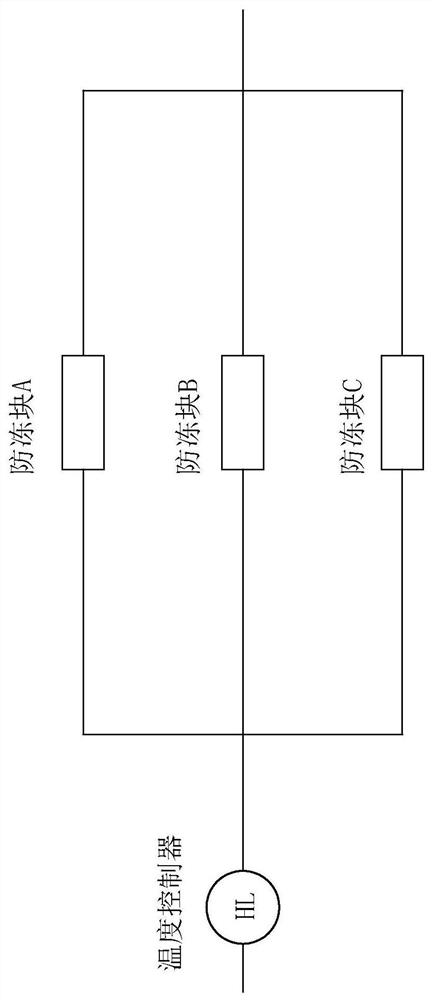

[0026] Such as figure 1 As shown, it is the antifreeze heating module used in the existing gas water heater. It is assumed that there are three antifreeze blocks A, B, and C, and the antifreeze blocks are all controlled by the temperature controller. The temperature controller assembly needs to be installed on the copper pipe for Collecting water temperature requires high installation and design costs; when the temperature controller checks that the temperature is lower than the set low temperature value (such as 5°C), the circuit of the antifreeze component function module is turned on, and the antifreeze block is heated to ensure that the low temperature in winter The drain pipe will not freeze and crack. This existing antifreeze component functional module is only applicable to winter antifreeze function, if run into when summer ambient te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com