Large-speed-difference flue gas circulation and ultralow nitrogen oxide high-speed burner and control method thereof

A flue gas circulation and nitrogen oxide technology, which is applied in combustion methods, furnace control devices, gas fuel burners, etc., can solve the problem of high emissions, and achieve the effect of reducing the calorific value of gas and reducing NOx emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: The present invention provides a high-speed burner with large speed difference flue gas circulation and ultra-low nitrogen oxides and its control method. The high-speed burner in this embodiment is used in a high-temperature tunnel-type annealing furnace for oriented silicon steel, using natural gas as fuel. The maximum furnace temperature of the annealing furnace reaches 1320°C.

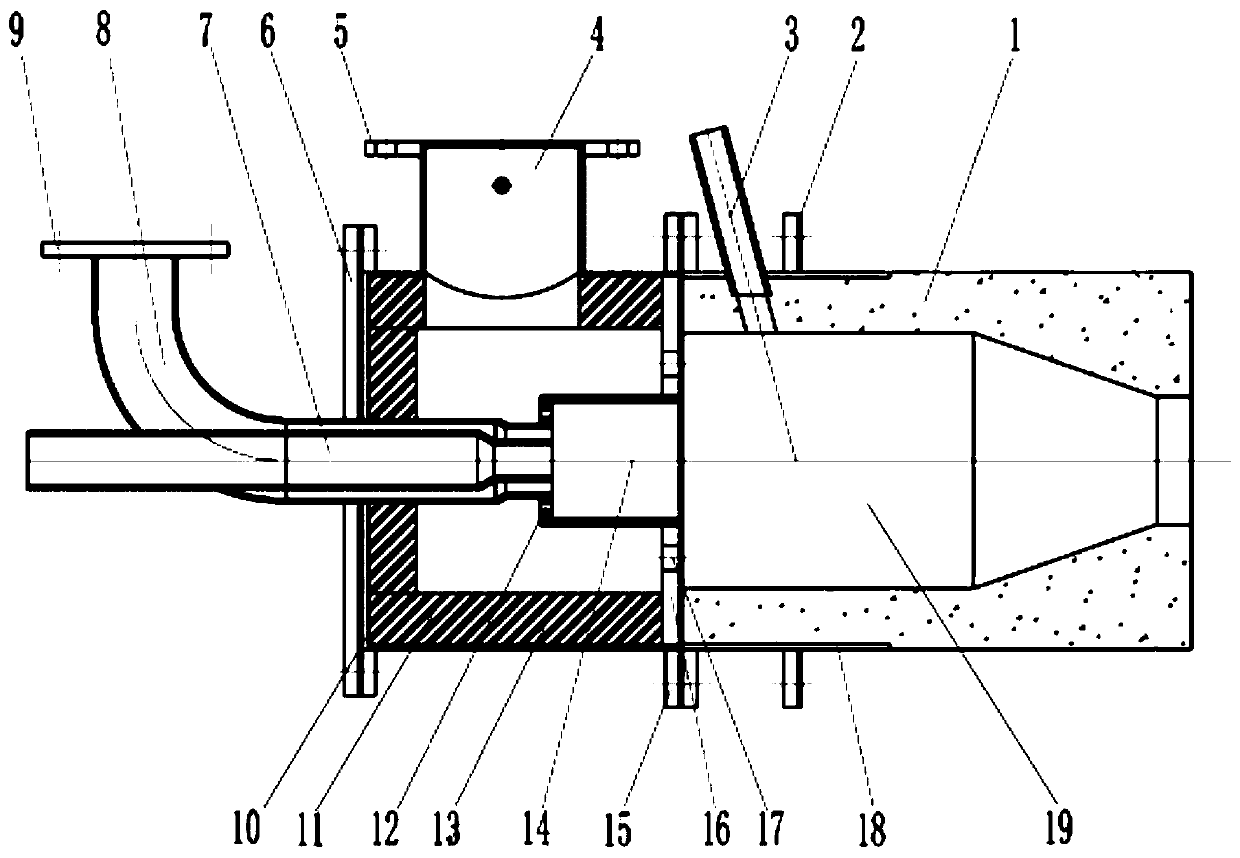

[0020] The structure of this high-speed burner is as follows: figure 1 As shown, there are burner brick 1, burner installation flange 2, ignition gun tube 3, air intake pipe 4, air intake pipe flange 5, fixed intake pipe flange 6, gas intake pipe 7, circulating flue gas inlet Trachea 8, circulating flue gas inlet pipe flange 9, burner housing flange A10, burner housing 11, pre-combustion chamber 14, burner housing flange B15, air distribution plate 16 and burner brick outer cylinder 18 The inner cavity of the burner brick 1 is used as the combustion chamber 19, the outer cylind...

Embodiment 2

[0028] Embodiment 2: The present invention provides a high-speed burner with large speed difference flue gas circulation and ultra-low nitrogen oxides and its control method. The high-speed burner in this embodiment is used for heating seamless steel pipes deal with Furnace, using coke oven gas as fuel, this heat deal with The maximum furnace temperature reaches 1050°C.

[0029] Wherein the structure of the high-speed burner is the same as that of Example 1, the only difference is that the control method of the burner is used. When the furnace temperature is lower than 900°C, 26% of the combustion-supporting air in the burner shell enters through the primary air inlet channel 12. The pre-combustion chamber 14 is pre-mixed with the coke oven gas entering the pre-combustion chamber through the gas inlet pipe 7 and combusted. The incompletely burned high-temperature flue gas generated after combustion is ejected into the burner brick at a flow rate of 2-5m / s In the combustion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com