Gradual-mode water turbine

A water turbine, progressive technology, applied in the field of impact water turbine, can solve the problems of small adaptability, pollution phenomenon, large hydraulic loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

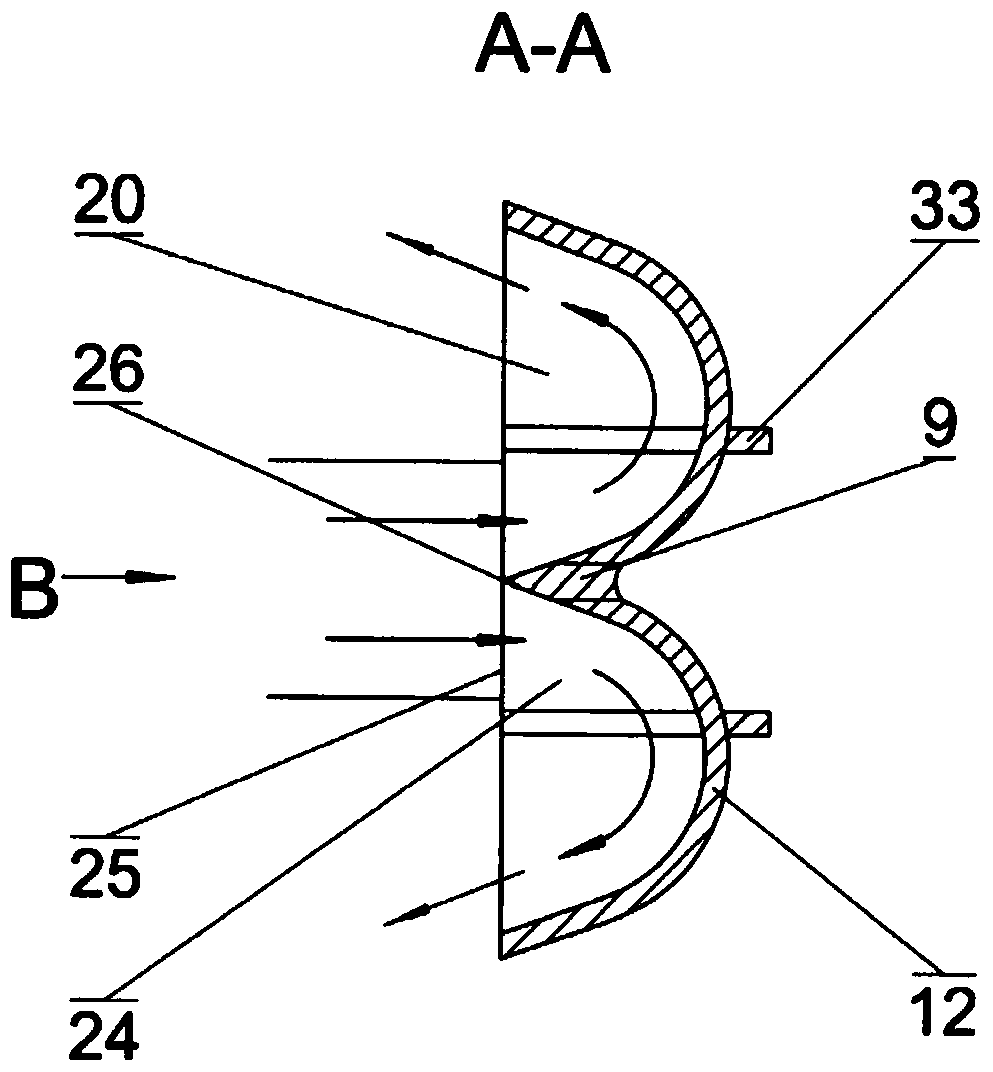

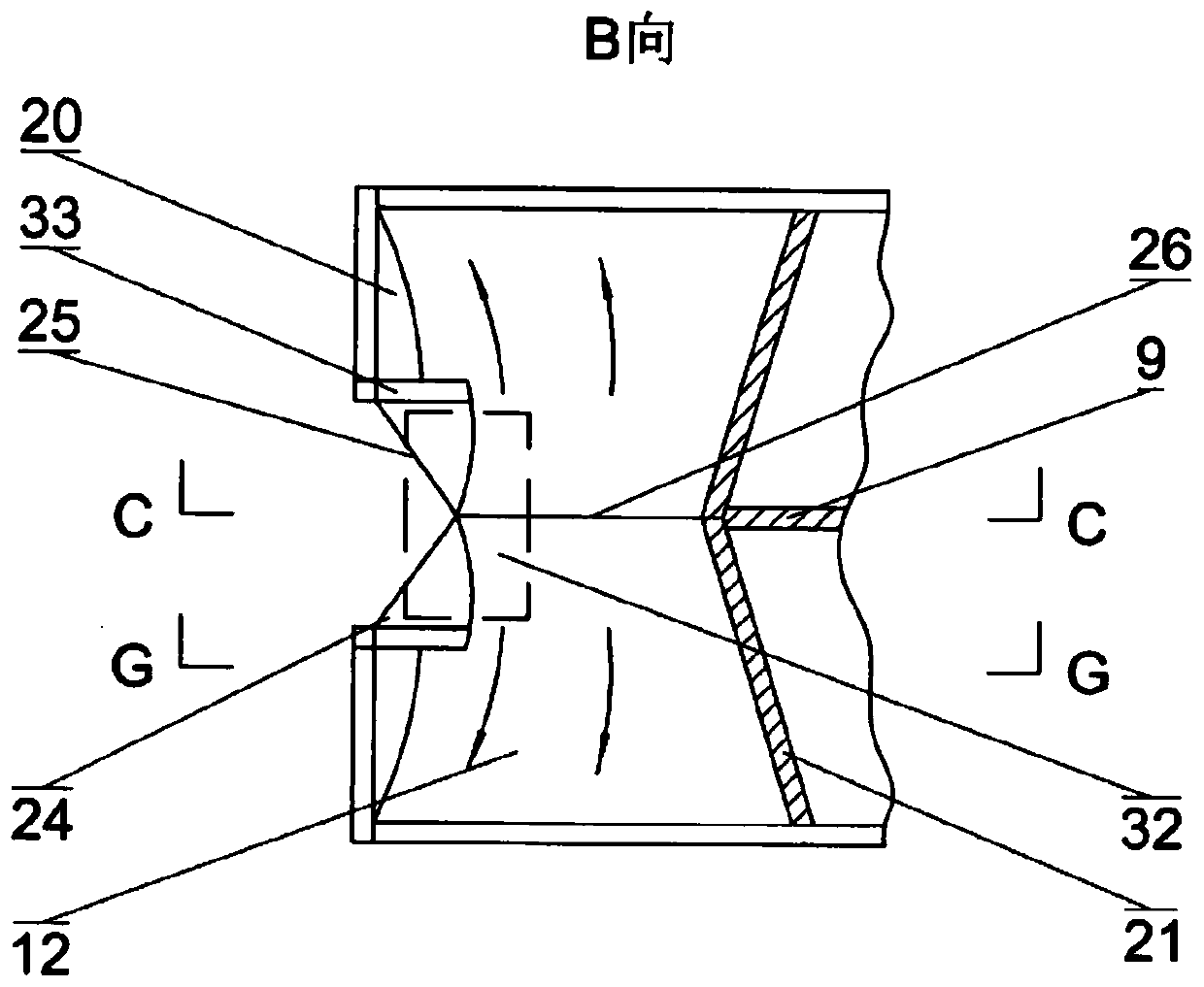

[0044] figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 A first embodiment of the invention is shown.

[0045] In this embodiment, the pressure water diversion chamber is connected with three rectangular pressure water diversion channels 2 arranged axially and horizontally, and respectively corresponding to the three runners installed on the main shaft 13 . One end of the main shaft 13 is indirectly rotationally connected to the main shaft of the generator through a speed increaser, and the other end is rotationally connected with a mechanical speed protection signal device.

[0046] As shown in the figure: the water outlet of the pressure water diversion channel 2 is equipped with a rectangular outlet 4, and the top of the outlet 4 is hinged with a rotary valve 16 that rotates according to the side shaft 17, and the top of the rotary valve 16 is provided with a transmission arm 7b. The arm 7 b is in transmission connection with the worm 31 , and the worm 31 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com