Water-based industrial dip-coating paint and preparation process thereof

A preparation process and industrial technology, which is applied in the field of water-based industrial dip coating and its preparation process, can solve the problems that the influencing factors of the dip coating preparation process are rarely analyzed, and achieve the effects of improving grinding efficiency, good dispersion, and reducing grinding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

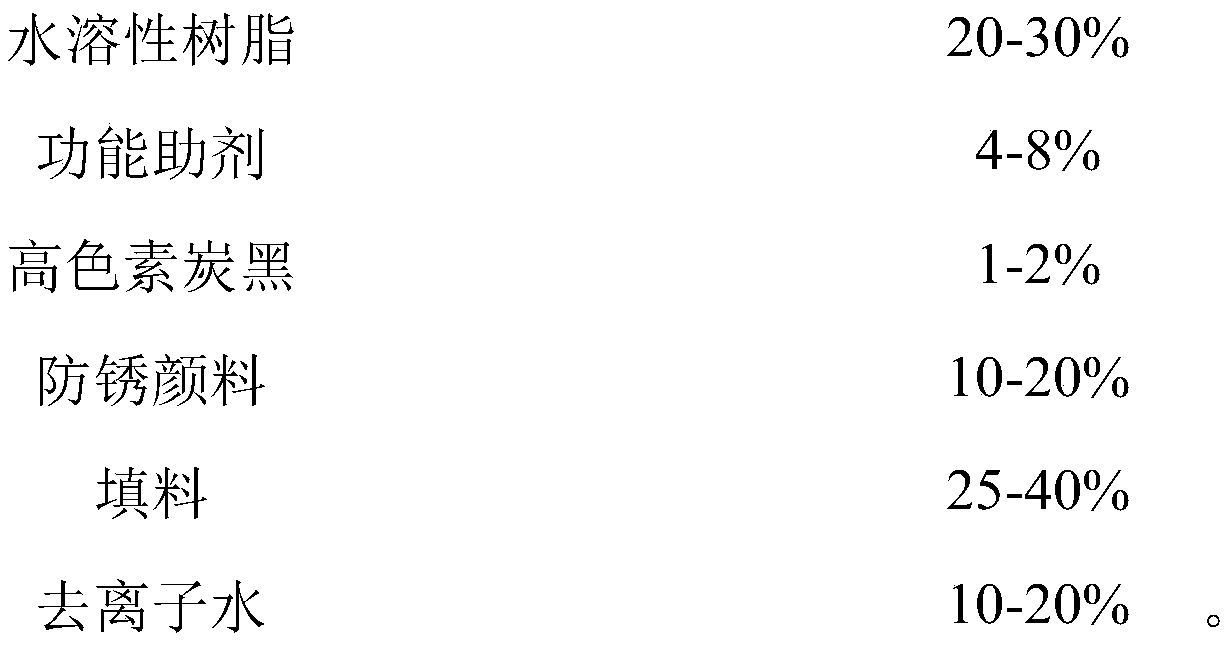

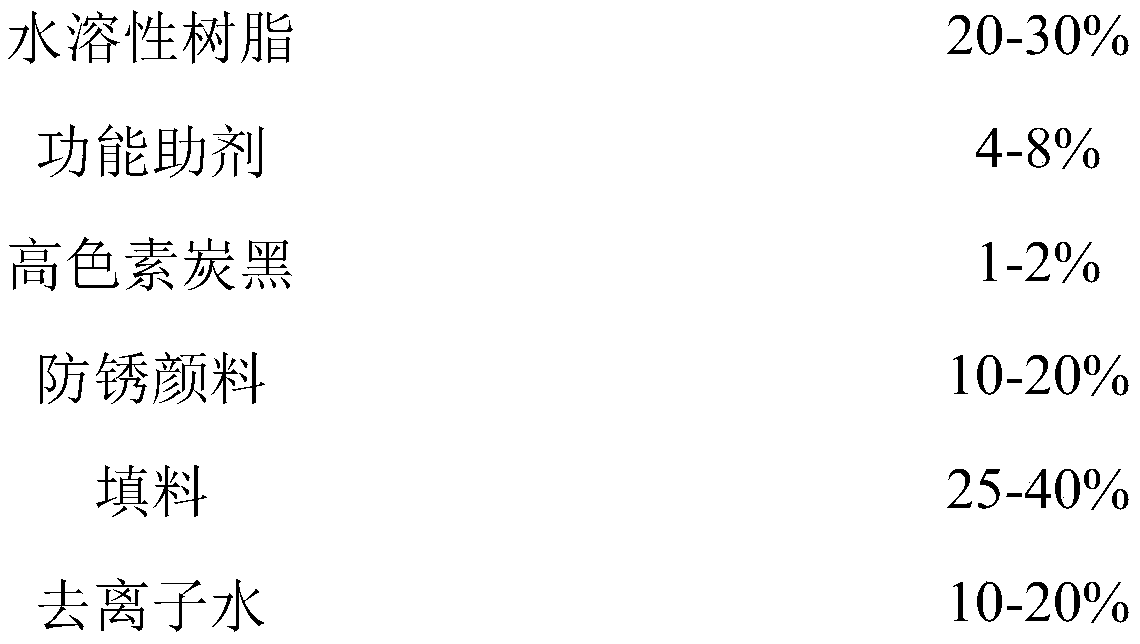

Method used

Image

Examples

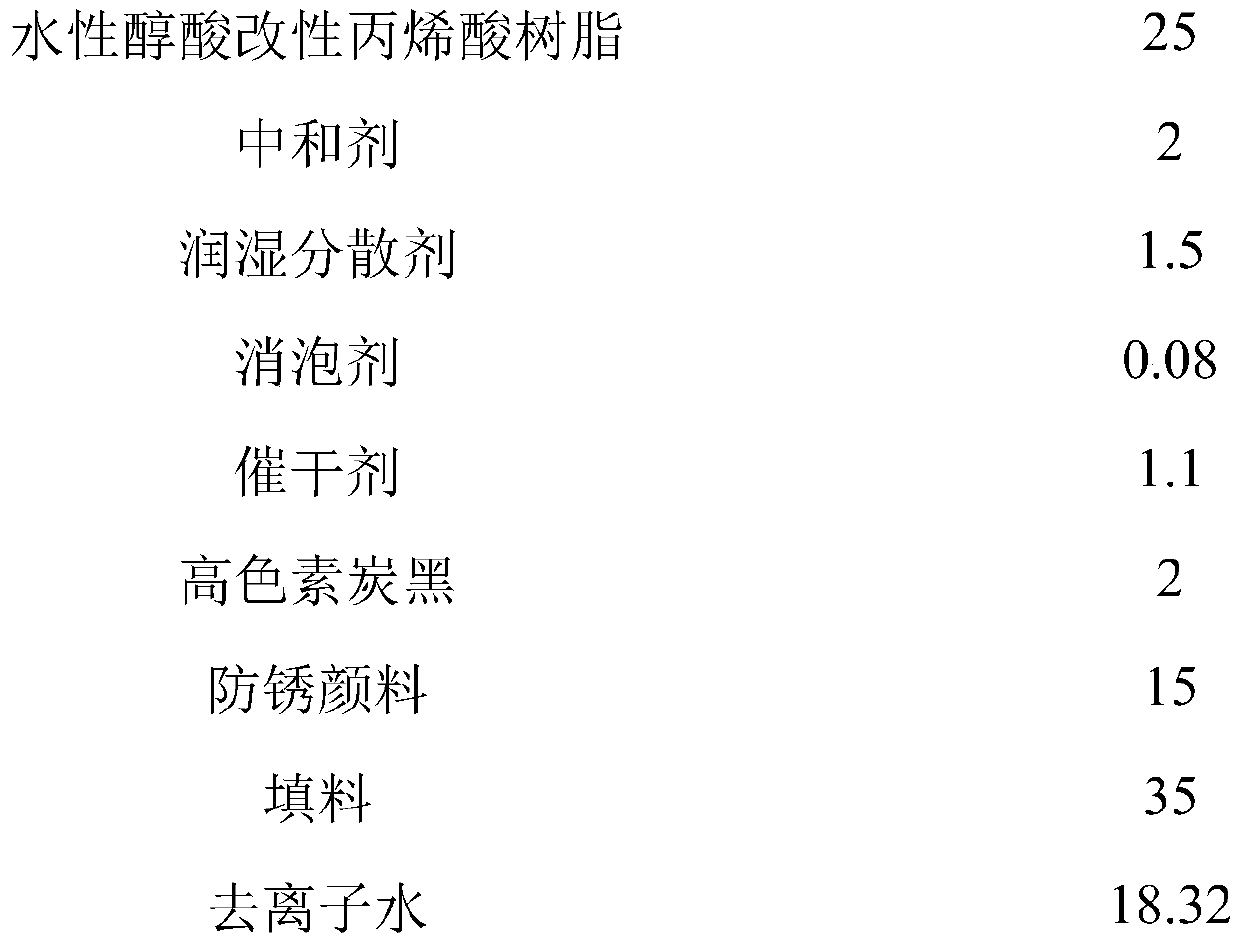

Embodiment 1

[0030] According to the preparation process of the above-mentioned formula water-based industrial dip coating:

[0031] Dispersion: Add water-based alkyd-modified acrylic resin, deionized water, neutralizer, wetting and dispersing agent, defoamer, drier, high-pigment carbon black, anti-rust pigment, and filler to the mixing tank in sequence according to the formula Medium, rotating speed 800r / min, disperse for 15min;

[0032] Grinding: Grind the dispersed slurry on a sand mill, and check the fineness every 15 minutes until the slurry fineness is ≤30 μm;

[0033] Thinning: put the slurry with qualified grinding fineness into the paint mixing container, and adjust to the required viscosity to obtain the water-based industrial dip coating.

Embodiment 2

[0035] According to the preparation process of the above-mentioned formula water-based industrial dip coating:

[0036] Dispersion: Add water-based alkyd-modified acrylic resin, deionized water, neutralizer, drier, defoamer, wetting and dispersing agent, high-pigment carbon black, antirust pigment, and filler to the mixing tank in sequence according to the formula Medium, rotating speed 800r / min, disperse for 15min;

[0037] Grinding: Grind the dispersed slurry on a sand mill, and check the fineness every 15 minutes until the slurry fineness is ≤30 μm;

[0038] Thinning: put the slurry with qualified grinding fineness into the paint mixing container, and adjust to the required viscosity to obtain the water-based industrial dip coating.

[0039] The above-mentioned Example 1 can be ground for 1.5 hours to reach the specified fineness of 30 μm, and Example 2 can be ground for 2 hours to reach the specified fineness of 30 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com