Modified titanium dioxide and preparation method and application thereof

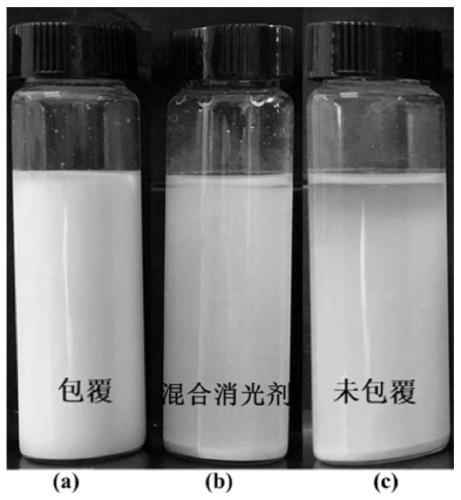

A titanium dioxide modification technology, applied in chemical instruments and methods, rayon manufacturing, textiles and papermaking, etc., can solve the problems of easy aggregation of titanium dioxide matting agent, poor weather resistance, etc., to reduce photodegradation ability and enhance hydrophilicity Sexuality, the effect of enhancing the binding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0072] This preparation example is used to prepare modified titanium dioxide, and the preparation method is as follows:

[0073] (1) Preparation of TiO 2 Dispersion liquid: first mix 20g of TiO 2 Slowly add 100mL deionized water to form TiO 2 suspension, sodium hexametaphosphate is contacted with water to form a concentration of 20wt% sodium hexametaphosphate solution, and then to the TiO 2 Add 0.2mL of the sodium hexametaphosphate solution to the suspension, and stir continuously for 1h at a stirring speed of 800rpm to obtain TiO 2 Concentration of 20wt% TiO 2 Dispersions;

[0074] (2) Add 0.06g tris (ie Tris) to the TiO 2 In the dispersion liquid, ultrasonic dissolution is prepared into a tris solution with a tris concentration of 5 mmol / L, and a hydrochloric acid solution with a hydrochloric acid concentration of 2 wt% is used to adjust the pH value of the tris solution 8.5, then add 0.1g levodopa at a stirring speed of 500rpm, add 0.05g catechol after dissolving, sti...

preparation example 2-7

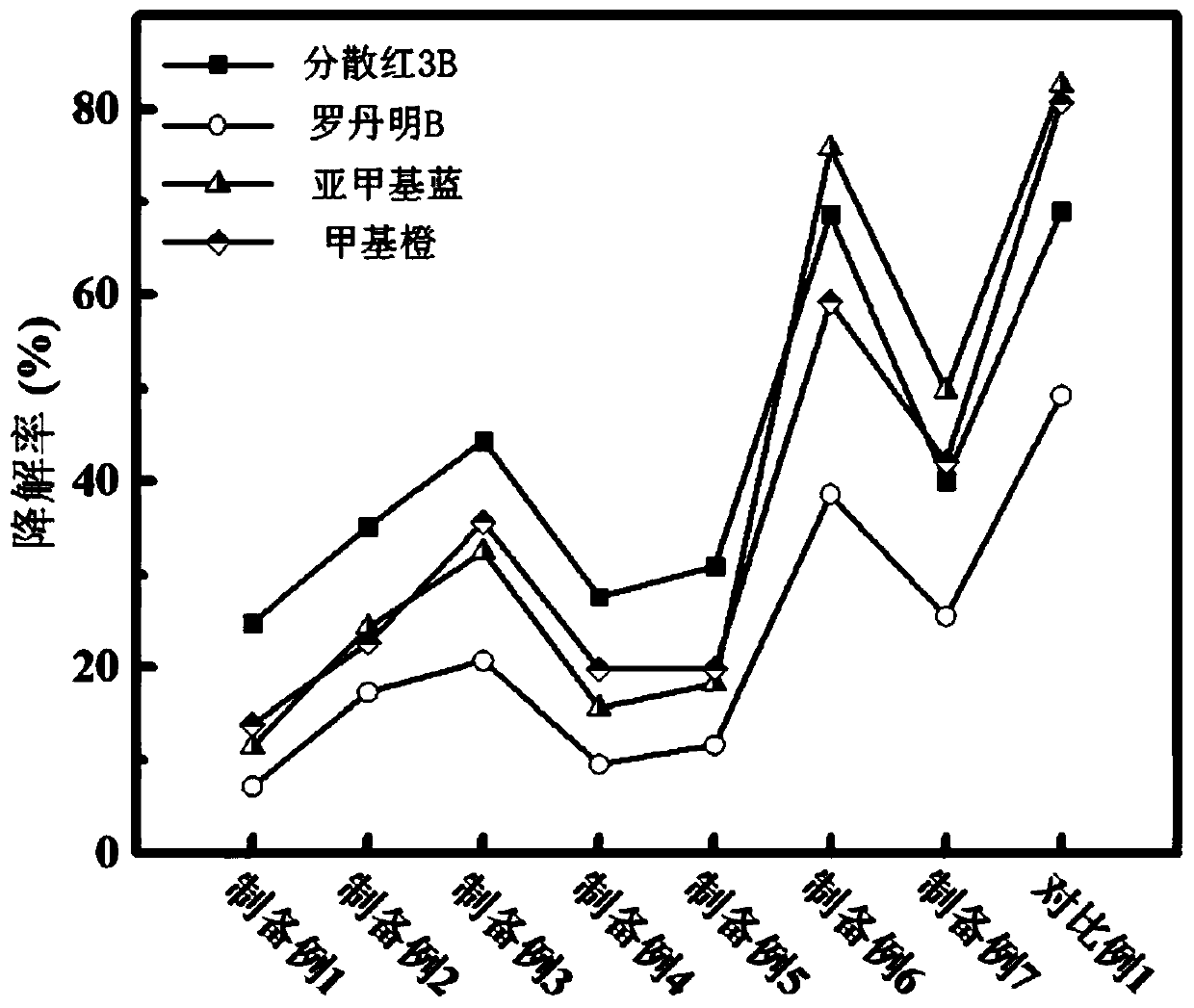

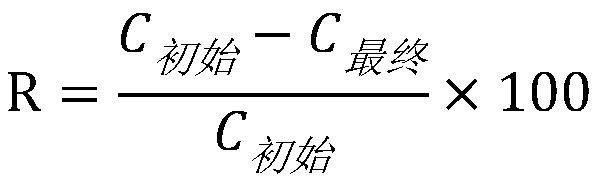

[0080] Prepare the modified titanium dioxide of this preparation example according to the method of preparation example 1, the difference is that the corresponding parameters in the following table 1 are used to replace the preparation parameters of preparation example 1, and the prepared modified titanium dioxide is used as a matting agent. Anti-ultraviolet performance, catalytic performance test, the results are shown in Table 1.

[0081] Table 1

[0082]

[0083] As can be seen from the results in Table 1, the modified titanium dioxide obtained from Examples 1-7 of the present invention has excellent anti-ultraviolet properties and lower catalytic activity; especially in the preferred range of levodopa consumption of the present invention , and the modified titanium dioxide prepared in Preparation Examples 1-5 within the preferred range of the molar ratio of the soluble barium salt to the soluble sulfate in the present invention has a more excellent effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com